Contaminated site risk management and control collaborative remediation system based on functional barrier

A technology of collaborative restoration and pollution restoration, applied in the field of environmental pollution restoration, can solve the problems of difficult restoration, secondary pollution, high pollution, etc., and achieve the effect of meeting the repair period requirements, facilitating installation and replacement, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

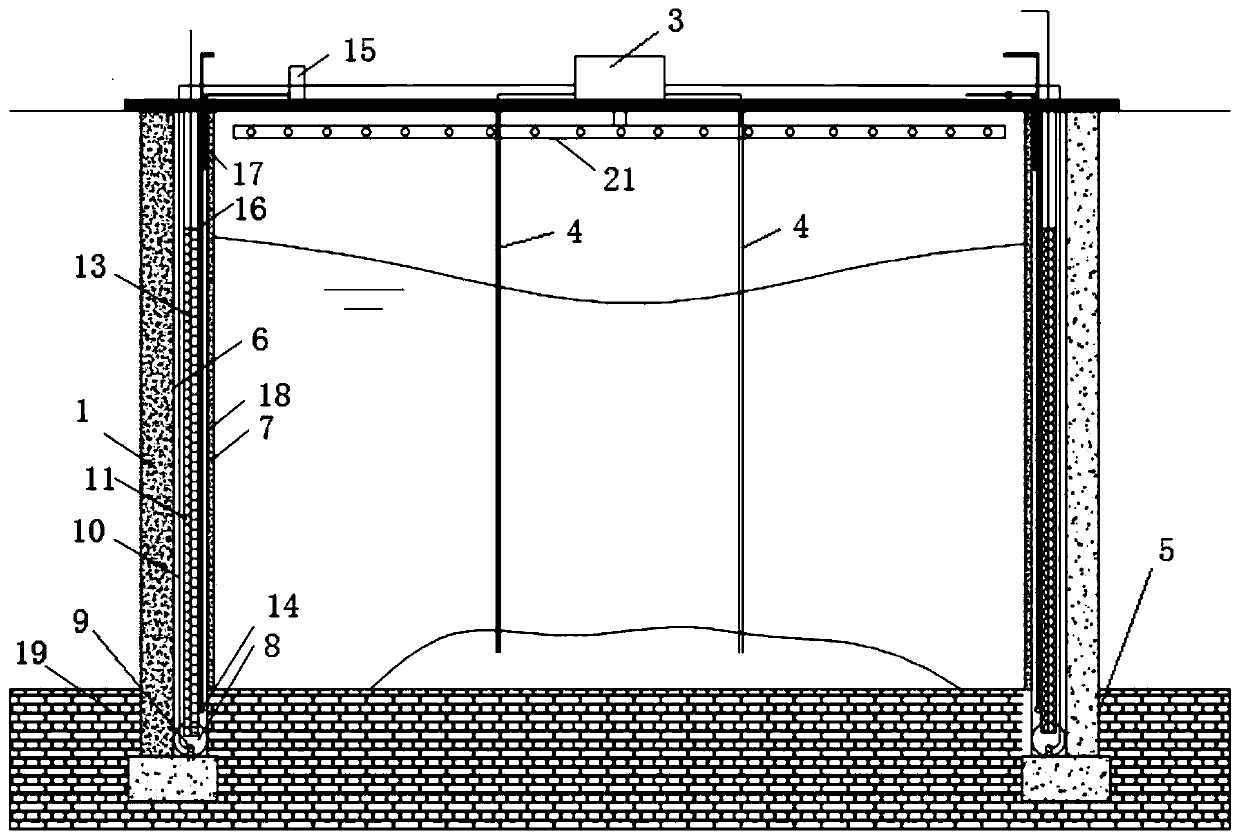

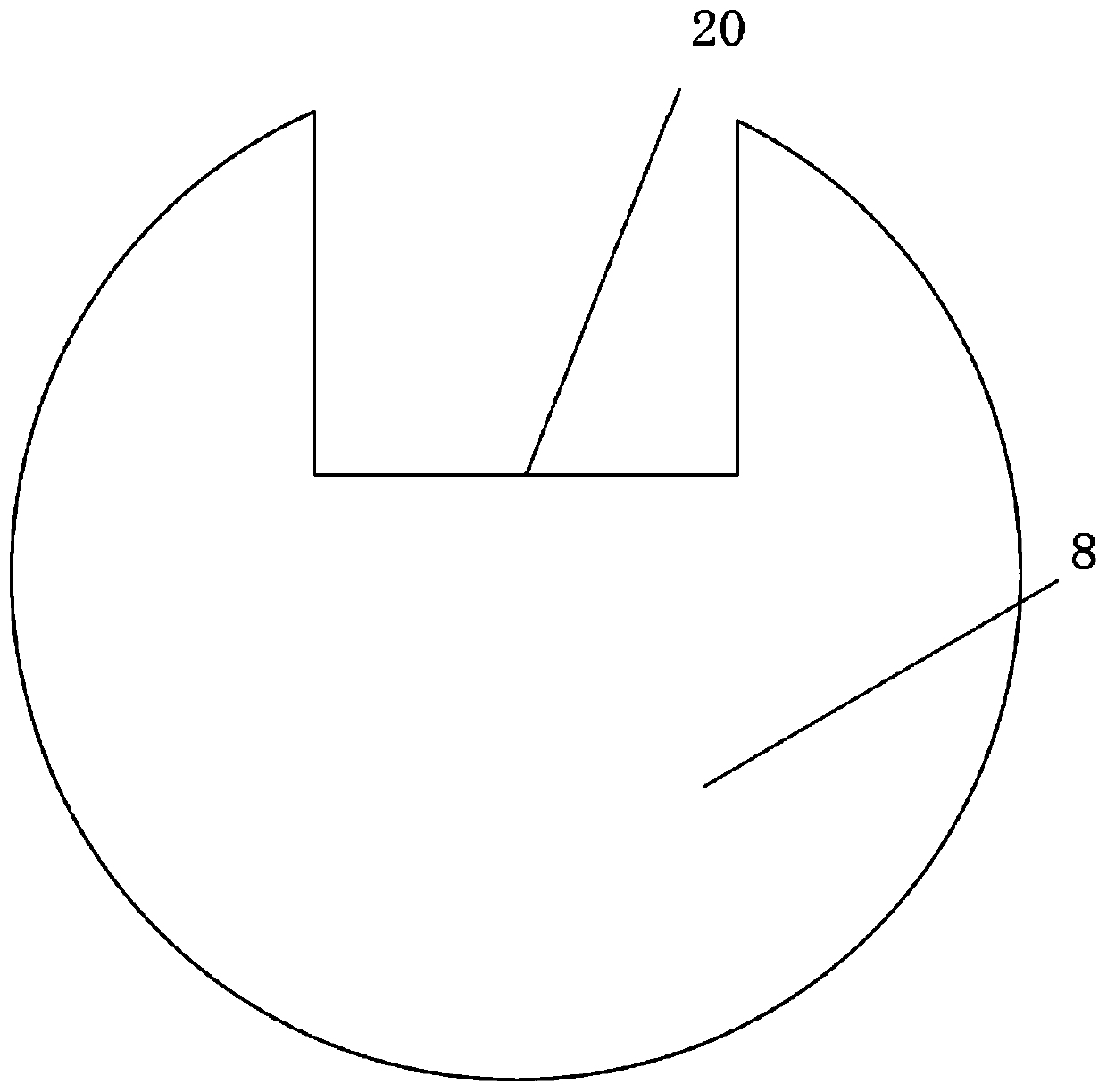

[0043] Such as Figure 1 to Figure 7 As shown, in order to achieve the above purpose, the present invention discloses a collaborative repair system for risk management and control of contaminated sites based on functional barriers; including pollution barrier area 1, pollution repair area 2, water treatment system 3 and recharge system; polluted groundwater is treated by water System 3 is recharged by the recharge system after purification.

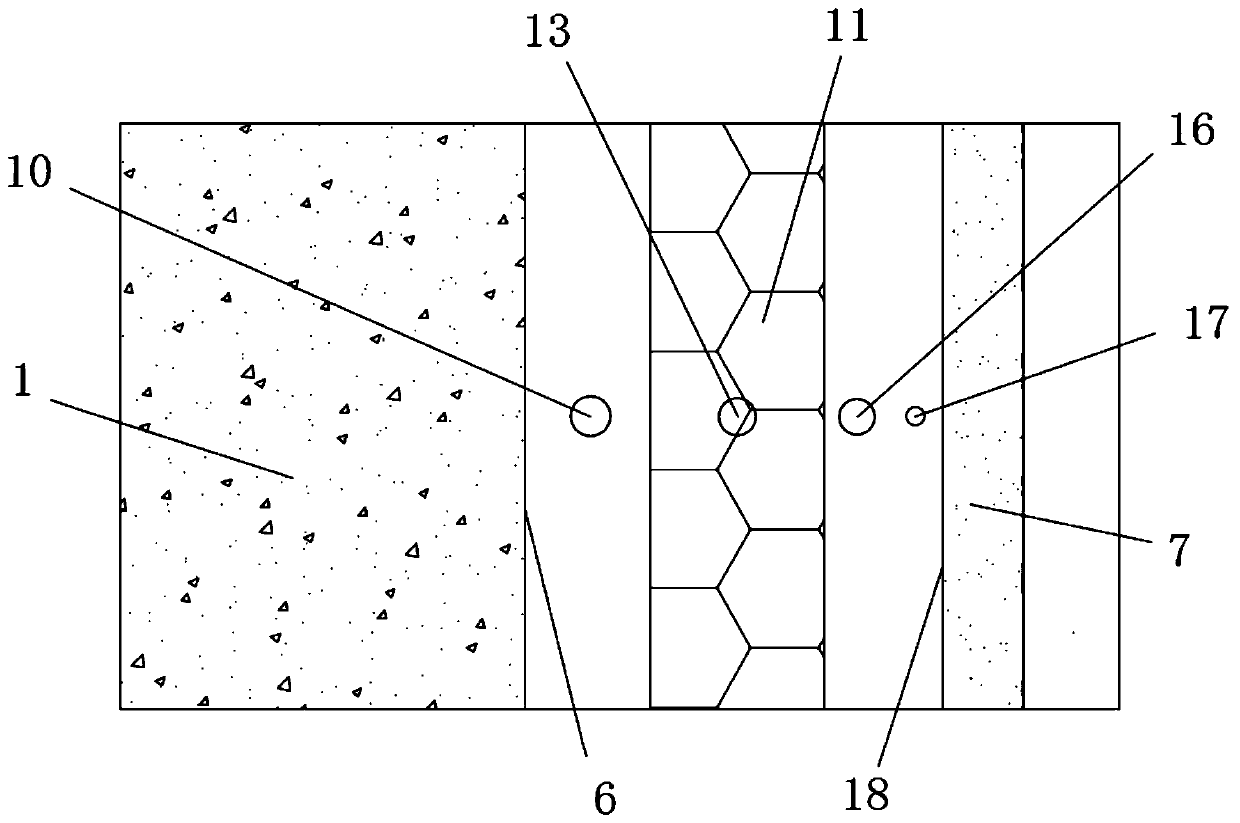

[0044] A ring trench 5 is arranged around the polluted site, and a pollution barrier area 1 and a pollution repair area 2 are arranged in the ring trench 5; the pollution barrier area 1 and the pollution repair area 2 are separated by a support plate 6;

[0045] The pollution barrier area 1 is located on the outside of the ring trench 5, and uses bentonite plus HDPE anti-seepage membrane structure to form a water seal. ;

[0046] The pollution remediation area 2 is located on the inner side of the ring field trench 5, including the coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com