Plastic-coated metal bar production line

A production line and metal strip technology, which is applied in the field of plastic packaging production, can solve problems such as poor stability, thin-walled features, and metal strips that cannot be effectively supported, so as to reduce the occupied area, ensure wall thickness, and improve space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

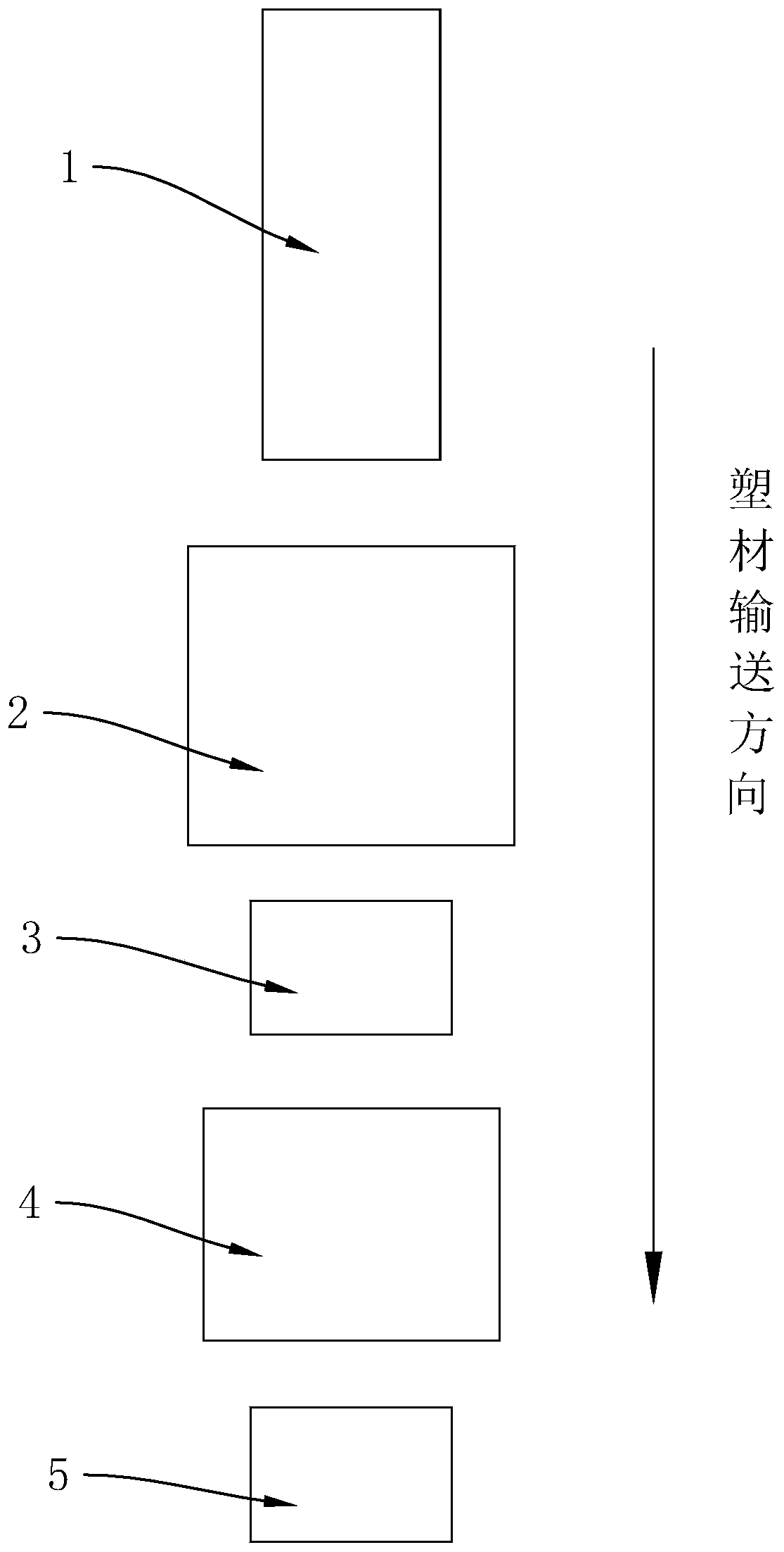

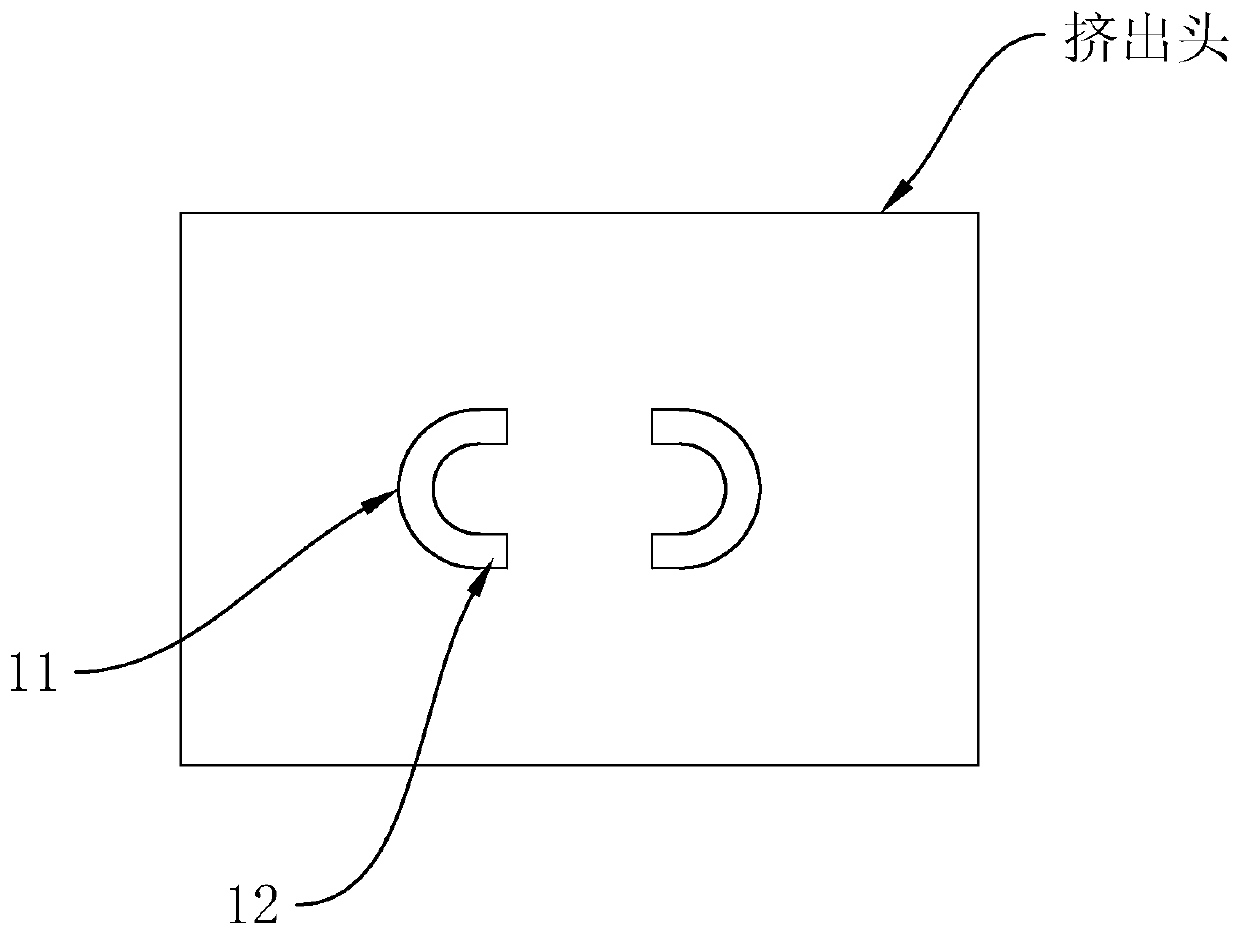

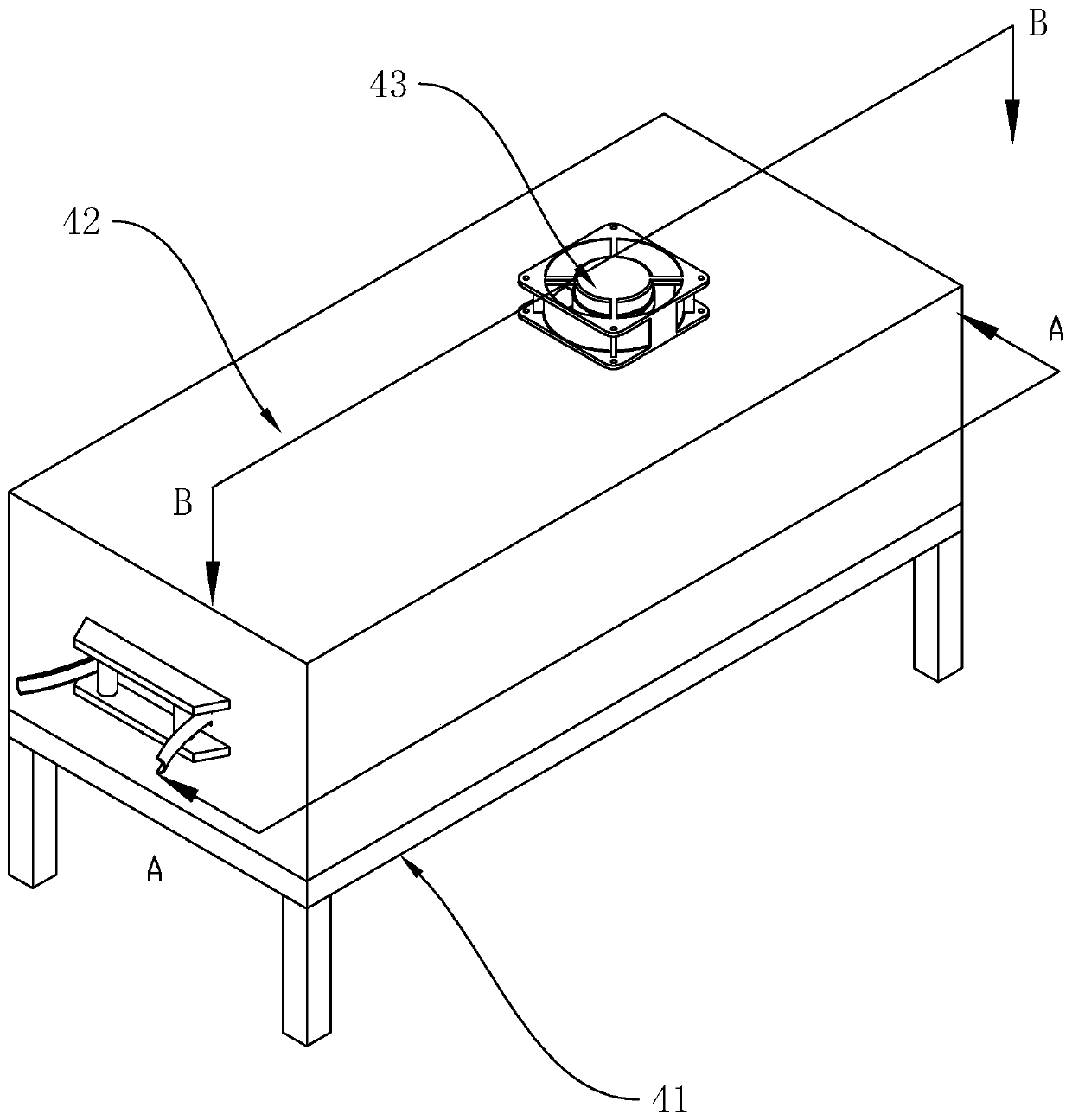

[0048] refer to figure 1 , which is a plastic-coated metal strip production line disclosed in the present invention, comprising a plastic-coating unit 1, a cooling unit 2, an unwinding unit 3, a heat-welding unit 4 and a winding unit 5 arranged in sequence; the plastic-coating unit 1 is set as a double Screw extruder, the overmolding unit 1 is used to extrude two semi-annular plastic materials with a cross-section in the shape of "U", the cooling unit 2 is set as a circulating cooling water tank, and the cooling unit 2 is used to put the overmolding unit 1. The extruded semi-circular plastic material is cooled and solidified. The unwinding unit 3 is set as a pay-off frame. The unwinding unit 3 is used to unwind the metal strip, and the unwinding unit 3 unwinds the metal strip through the overheating welding Unit 4, the heat welding unit 4 is used to wrap two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com