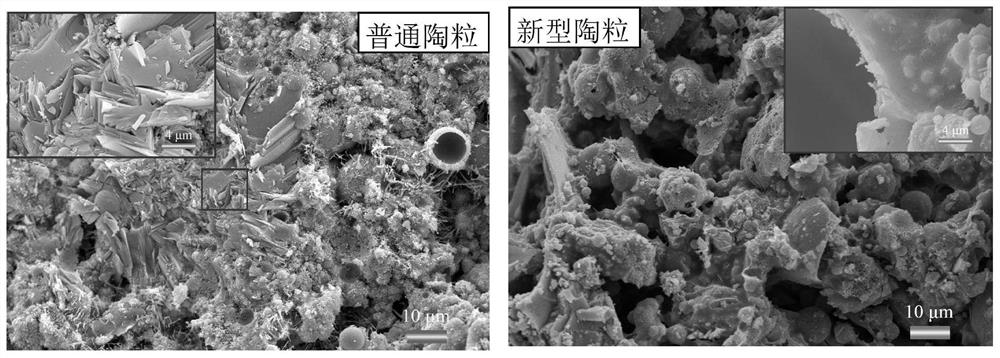

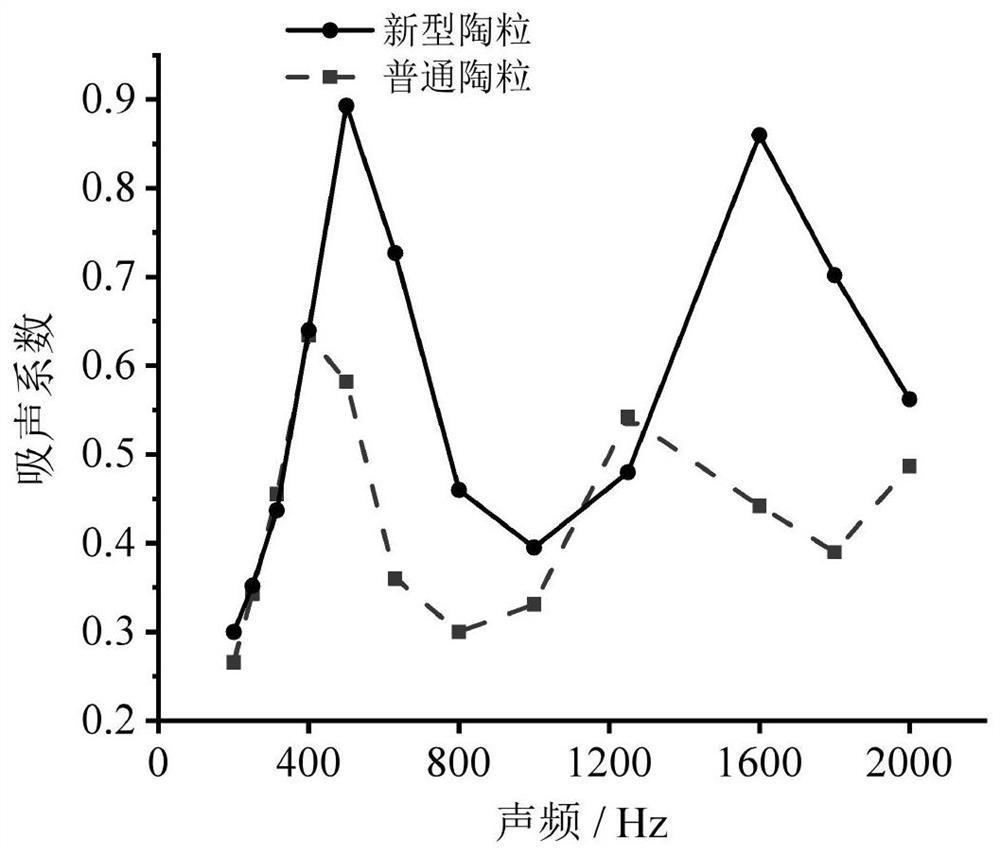

A preparation method and product of porous ceramsite and its application in sound-absorbing panels for concrete subway tracks

A porous pottery and concrete technology, applied in ceramic products, rails, applications, etc., can solve the problems of large emissions, poor performance of sinter-free ceramsite, and no sound absorption and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

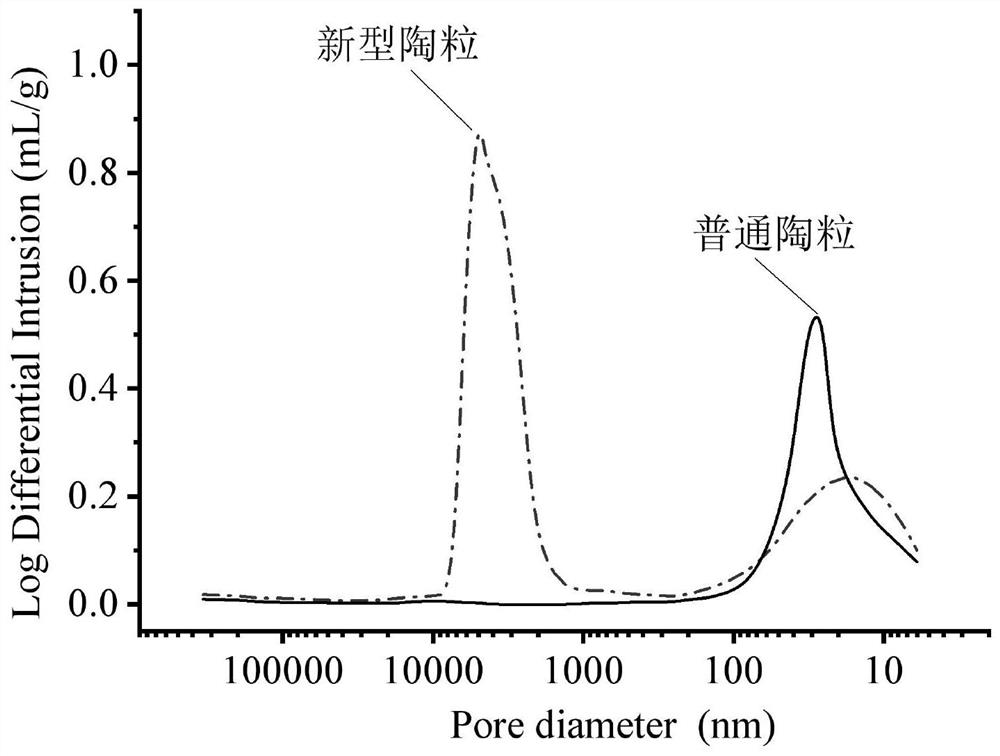

[0069] The present embodiment provides a kind of preparation method and product of porous ceramsite:

[0070] (1) After mixing fly ash, cement, lime and gypsum evenly (the average particle size of the starting powder of fly ash, cement, lime and gypsum is 22 μm, and the mass ratio of fly ash, cement, lime and gypsum is 25 :5:2:1), ball milling (mass ratio of grinding balls to mixture 12:1, ball milling speed is 50rpm, ball milling time is 30min), and the starting powder after ball milling is obtained, and its average particle size is 13 μm;

[0071] (2) The original expanded perlite raw material (through a 90-mesh sieve) is ball milled (the mass ratio of the grinding ball to the expanded perlite is 12:1, the ball milling speed is 50rpm, and the ball milling time is 6min) to obtain expanded perlite powder after ball milling as a pore-forming material;

[0072] (3) The starting powder after ball milling and the expanded perlite powder after ball milling are mixed evenly in the ...

Embodiment 2

[0091] (1) After mixing fly ash, cement, lime and gypsum evenly (the average particle size of the starting powder of fly ash, cement, lime and gypsum is 22 μm, and the mass ratio of fly ash, cement, lime and gypsum is 25 :5:2:1), ball milling (mass ratio of grinding balls to mixture 12:1, ball milling speed is 50rpm, ball milling time is 30min), and the starting powder after ball milling is obtained, and its average particle size is 13 μm;

[0092] (2) Granulate the initial powder after ball milling in (1). The first 30s of granulator speed is 45rpm. After the powder turns into uniform fine sand, adjust the granulator speed to 30rpm. The total time is controlled as For 25 minutes, the pure aqueous solution is sprayed to evenly wet the powder mixture during the granulation process. The mass ratio of pure water to the mixed raw materials is 1:5 to obtain spherical pellets;

[0093] (3) Put the spherical pellets prepared in (2) into an autoclave, heat up to 110°C at a rate of 5°C...

Embodiment 3

[0095] (1) After mixing fly ash, cement, lime and gypsum evenly (the average particle size of the starting powder of fly ash, cement, lime and gypsum is 22 μm, and the mass ratio of fly ash, cement, lime and gypsum is 25 :5:2:1), ball milling (mass ratio of grinding balls to mixture 12:1, ball milling speed is 50rpm, ball milling time is 30min), and the starting powder after ball milling is obtained, and its average particle size is 13 μm;

[0096] (2) Granulate the initial powder after ball milling in (1). The first 30s of granulator speed is 45rpm. After the powder turns into uniform fine sand, adjust the granulator speed to 30rpm. The total time is controlled as 25min, the blowing agent solution is sprayed to uniformly wet the powder mixture (a certain amount of ammonium bicarbonate is transferred to the container with water to obtain a concentration of 2.0wt.% blowing agent solution) while the granulation process is performed. And the mass ratio of mixed raw material is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com