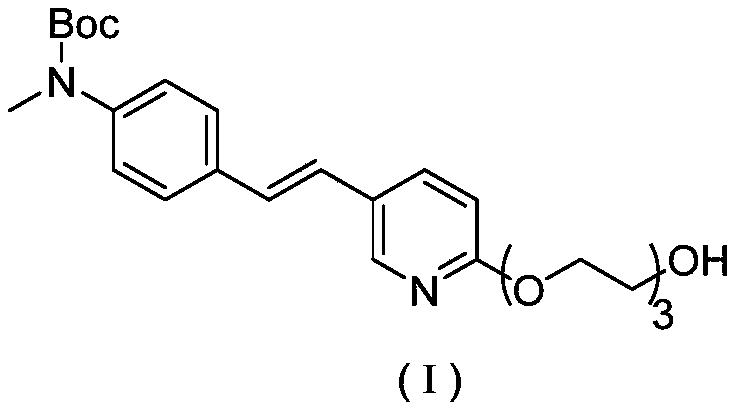

Synthesis method of AV-45 intermediate

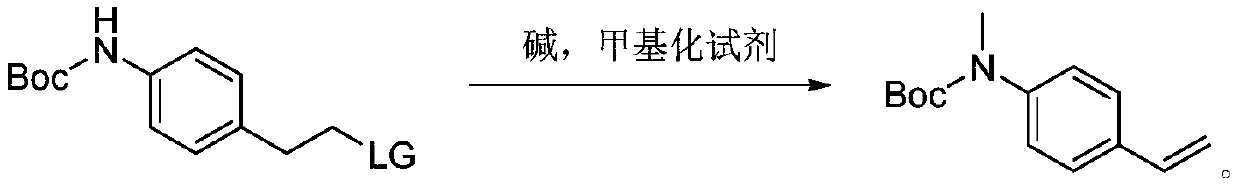

A synthesis method and tert-butyl technology are applied in the preparation of amino compounds from amines, organic chemistry, etc., can solve problems such as low yield, long reaction route, inconvenient post-processing, etc., and achieve high yield, low cost, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

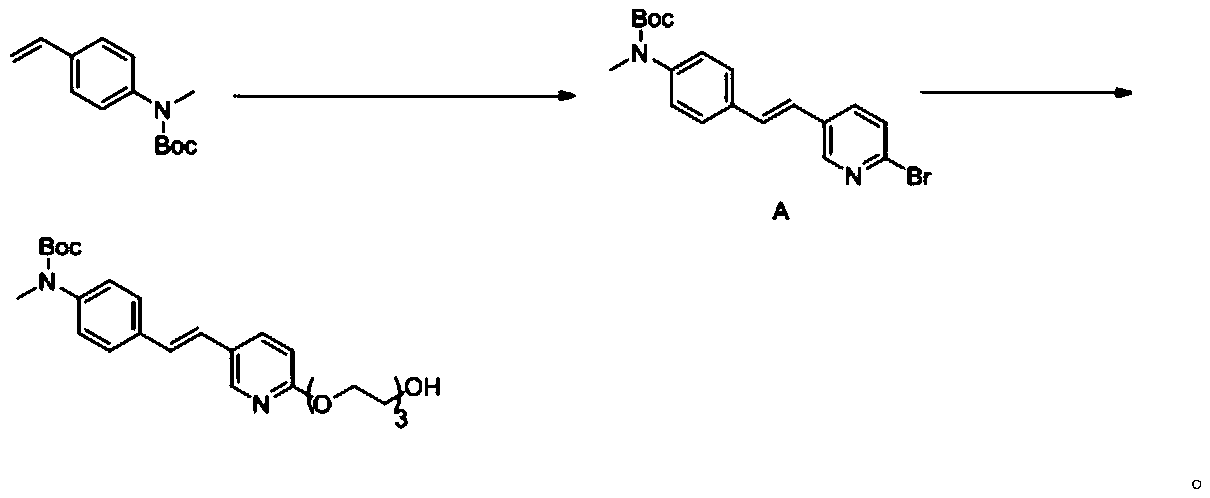

[0048] Under nitrogen protection, tert-butyl-N-methyl-4-vinylphenylcarbamate (5.13g, 22mmol), 2-bromo-5-iodopyridine (5.66g, 20mmol), TBAB (12.9 g, 40mmol), K 2 CO 3 (6.91g, 50mmol), Pd(OAc) 2 (224mg, 1.0mmol) was suspended in 150mL DMF and reacted at 65°C for 3 hours. Cool down to room temperature, add 300 mL of water, and extract with ethyl acetate (300 mL×3). The organic phases were combined and washed with saturated brine (500 mL×2). The organic phase was dried over anhydrous sodium sulfate. After concentration under reduced pressure, the crude product was recrystallized from dichloromethane / n-hexane to obtain 6.43 g of white solid, with a yield of 82.6%.

Embodiment 2

[0050] Under nitrogen protection, tert-butyl-N-methyl-4-vinylphenylcarbamate (5.13g, 22mmol), 2-bromo-5-iodopyridine (5.68g, 20mmol), PdCl 2 (177mg, 1.0mmol), TBAB (645mg, 2mmol), K 2 CO 3 (2.76g, 20mmol) was suspended in 100mL DMF and reacted at 65°C for 3 hours. Cool down to room temperature, add 200 mL of water, and extract with ethyl acetate (200 mL×3). The organic phases were combined and washed with saturated brine (500 mL×2). The organic phase was dried over anhydrous sodium sulfate. After concentration under reduced pressure, the crude product was recrystallized from acetonitrile to obtain 6.03 g of a white solid with a yield of 77.4%.

Embodiment 3

[0052] Under nitrogen protection, tert-butyl-N-methyl-4-vinylphenylcarbamate (5.13g, 22mmol), 2-bromo-5-iodopyridine (5.68g, 20mmol), Pd(OAc ) 2 (224mg, 1.0mmol), TBAB (645mg, 2mmol), K 2 CO 3 (2.76g, 20mmol) was suspended in 100mL DMF and reacted at 65°C for 3 hours. Cool down to room temperature, add 200 mL of water, and extract with ethyl acetate (200 mL×3). The organic phases were combined and washed with saturated brine (500 mL×2). The organic phase was dried over anhydrous sodium sulfate. After concentration under reduced pressure, the crude product was recrystallized from acetonitrile to obtain 5.87 g of a white solid with a yield of 75.4%.

[0053] Step (2): Intermediate A is condensed with triethylene glycol to obtain a compound of formula (I)

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com