Surface protectant for semiconductor wafer

A surface protectant, semiconductor technology, applied in the manufacture of semiconductor/solid state devices, surface etching compositions, polishing compositions containing abrasives, etc., can solve the problems of scratches, scratches, easy agglomeration, etc. , The effect of reducing scratches, high flatness and low defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

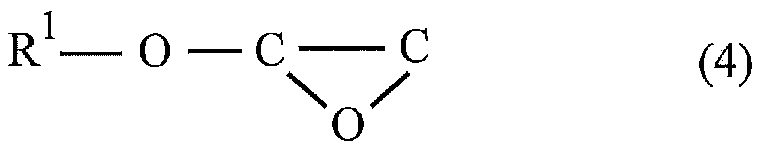

[0086] 4 mol of 2,3-epoxy-1-propanol (trade name "Glycidol", manufactured by Daicel Co., Ltd.) was added to 1 mol of lauryl alcohol to obtain compound (A1) (C 12 h 25 O-(C 3 h 6 o 2 ) 4 -H, molecular weight: 482).

[0087] The obtained compound (A1) was diluted with water so that the concentration of the obtained compound (A1) became 15% by weight, and a semiconductor wafer surface protective agent (A1) was obtained.

Embodiment 2

[0089] The consumption of 2,3-epoxy-1-propanol was changed to 10mol, except that, compound (A2) was obtained in the same manner as in Example 1 (C 12 h 25 O-(C 3 h 6 o 2 ) 10 -H, molecular weight: 926).

[0090] The obtained compound (A2) was diluted with water so that the concentration of the obtained compound (A2) became 15 weight%, and the semiconductor wafer surface protective agent (A2) was obtained.

Embodiment 3

[0092] The consumption of 2,3-epoxy-1-propanol was changed to 6mol, except that, compound (A3) was obtained in the same manner as in Example 1 (C 12 h 25 O-(C 3 h 6 o 2 ) 6 -H, molecular weight: 630).

[0093] The obtained compound (A3) was diluted with water so that the concentration of the obtained compound (A3) became 15 weight%, and the semiconductor wafer surface protective agent (A3) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com