Polishing layer, polishing pad and preparation method

A polishing layer and polishing pad technology, which is applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc. Effect of meta wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

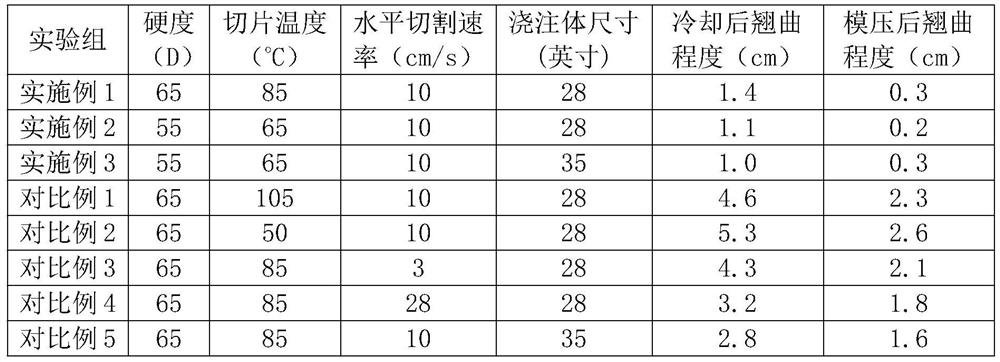

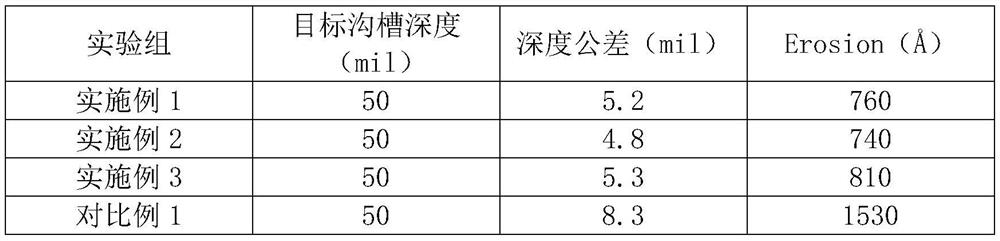

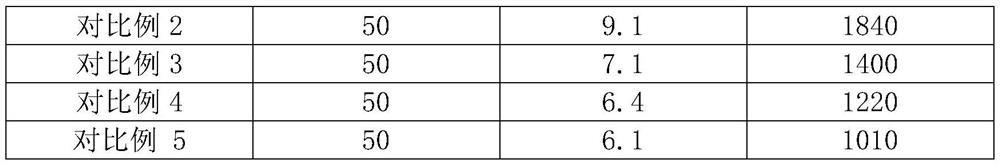

[0089] Casting body a (65D, 28 inches) is cooled to 90°C within 2 hours and taken out. Move the mold to a slicer to fix it, and adjust the horizontal moving speed of the slicer knife to 10cm / min. The cast body was heated with an infrared lamp and kept at 90°C. Start slicing after 10 min of incubation. The sliced sample was placed flat and cooled at 25°C for 12 hours. The Shore hardness was tested to be 65D. The die was pressed flat for 12 hours to measure the warpage of the die before and after molding (the five points with the largest warpage and the distance between the five points on the horizontal plane) mean height difference), the results are shown in Table 1.

Embodiment 2

[0091] The pouring body b (55D, 28 inches) was cooled to 65°C within 2 hours and then taken out. Move the mold to a slicer to fix it, and adjust the horizontal moving speed of the slicer knife to 10cm / min. The cast body was heated with an infrared lamp and kept warm to 65°C. Start slicing after 10 min of incubation. The sliced samples were placed flat and cooled at 25°C for 12 hours. The Shore hardness was tested to be 55D. The dies were pressed flat for 12 hours to measure the warpage of the die before and after molding. The results are shown in Table 1.

Embodiment 3

[0093] The casting body b (55D, 35 inches) was cooled to 65°C within 2 hours and then taken out. Move the mold to a slicer to fix it, and adjust the horizontal moving speed of the slicer knife to 10cm / min. The cast body was heated with an infrared lamp and kept warm to 65°C. Start slicing after 10 min of incubation. The sliced samples were placed flat and cooled at 25°C for 12 hours. The Shore hardness was tested to be 55D. The dies were pressed flat for 12 hours to measure the warpage of the die before and after molding. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com