Preparation method of Q460 hot rolled round steel for rare earth low-temperature-resistant automobile part

A technology for auto parts and low temperature resistance, which is applied in the field of preparation of Q460 hot-rolled round steel for rare earth and low temperature resistant auto parts, can solve the problems of high manufacturing cost, complex chemical composition and high production cost, and achieves improved processing performance and welding. Performance, obvious metamorphism, obvious purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

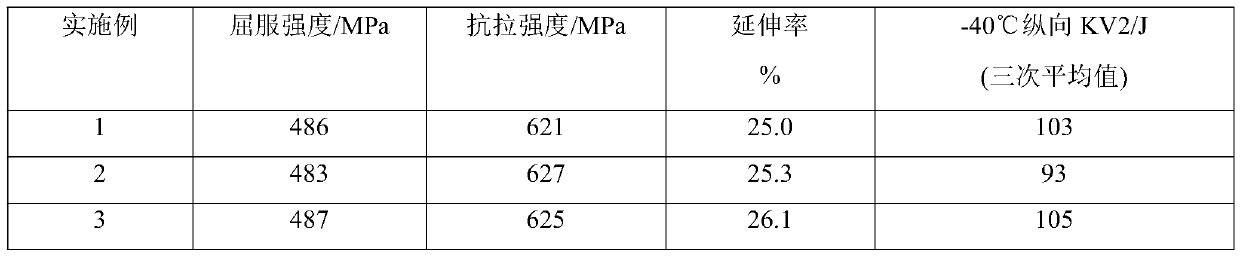

Examples

Embodiment Construction

[0027] A preparation method of Q460 hot-rolled round steel for rare earth low-temperature resistant auto parts, the chemical composition of the Q460 hot-rolled round steel is: C: 0.12-0.15%, Mn: 1.40-1.55%, Si: 0.30- 0.40%, V: 0.80-1.00%, Ni: 0.20-0.40%, RE: 0.01-0.02%, P: ≤0.010%, S: ≤0.005%, the rest is iron and unavoidable trace chemical elements;

[0028] Its steelmaking process is: converter—external refining—VD vacuum treatment—continuous casting; steel rolling process is: billet heating—high pressure water dephosphorization—Ф850mm blanking machine—Ф700mm×3+Ф550mm×4 continuous rolling unit rolling Manufacturing—sawing—slow cooling—nondestructive testing—stacking—inspection—grinding—bundling—storage—delivery; the technical parameters controlled in the rolling process are: heating temperature 1200—1250°C, holding time ≥ 2.5 hours; start rolling temperature ≤ 1150°C; finish rolling temperature ≤ 850°C; slow cooling time ≥ 48 hours; the structure after rolling is ferrite + p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elongation after break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap