Device used for coating fabric with salt powder and coating method

A salt powder and coating technology, applied in the field of chemical fiber coating equipment, can solve problems such as difficulties, high production costs, time-consuming chemical methods, etc., and achieve the effect of small ventilation pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

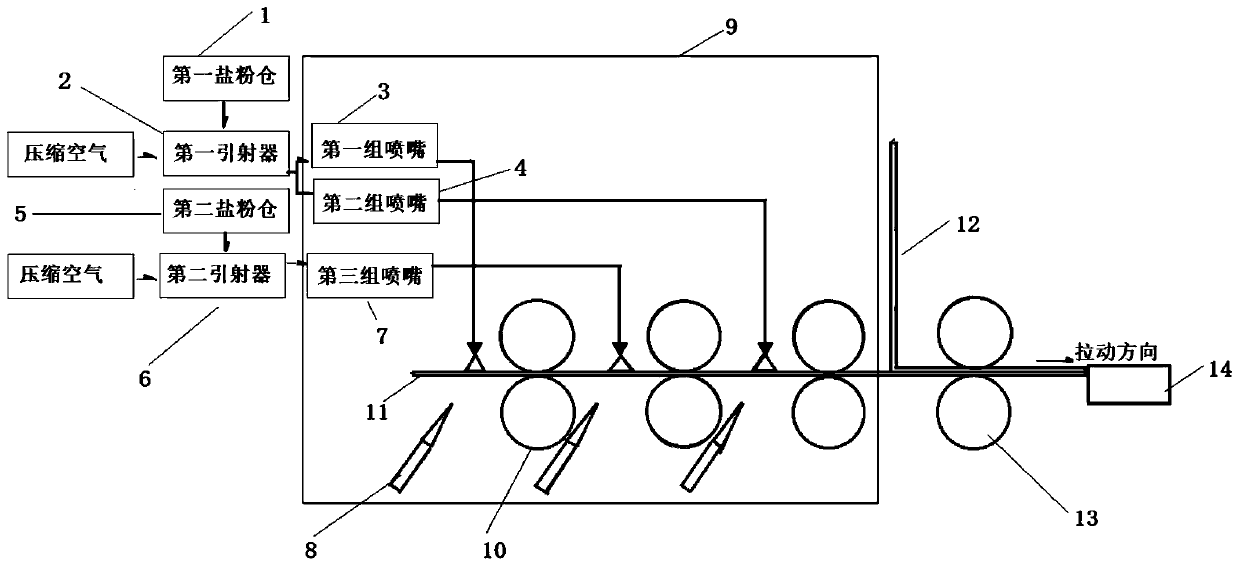

[0037] The present invention will be further described now in conjunction with accompanying drawing.

[0038] In this embodiment, the "salt powder", "salt powder layer" and "salt powder jet" all refer to sodium chloride salt powder or sodium chloride granular layer.

[0039] The invention provides a device for coating salt powder on fabrics, such as figure 1 As shown, it includes: the first salt powder bin 1, the first ejector 2, the first nozzle group 3, the second nozzle group 4, the second salt powder bin 5, the second ejector 6, and the third nozzle group 7. Three steam nozzles 8, temperature control chamber 9, three first pair of pressing rollers 10 and second pair of pressing rollers 13;

[0040] The first salt powder bin 1 is located above the first ejector 2, and introduces large-grained salt powder into the first ejector 2; the first ejector 2 is connected with the first nozzle group 3 located in the temperature control chamber 9 Connected with the second nozzle gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com