Construction device and method for underwater grouting

A technology for underwater grouting and construction equipment, which is applied in the direction of cement mixing equipment, unloading equipment, clay preparation equipment, etc., can solve the problems of not having, not having fast fixing mechanism, not having fast and uniform mixing of raw materials, etc., to achieve the guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

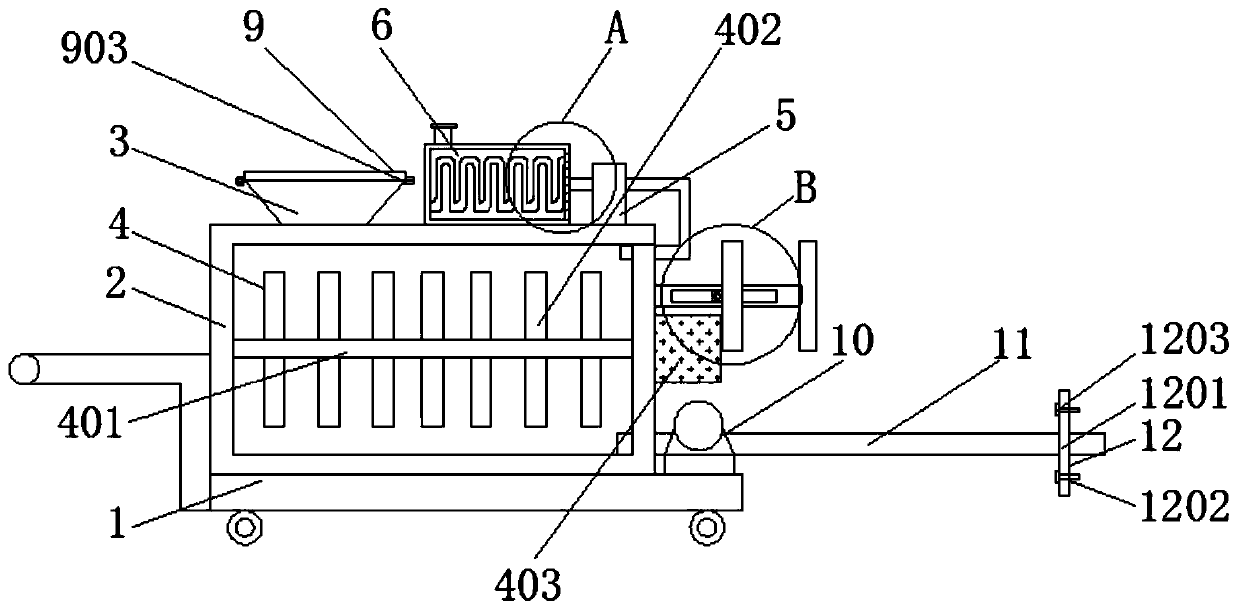

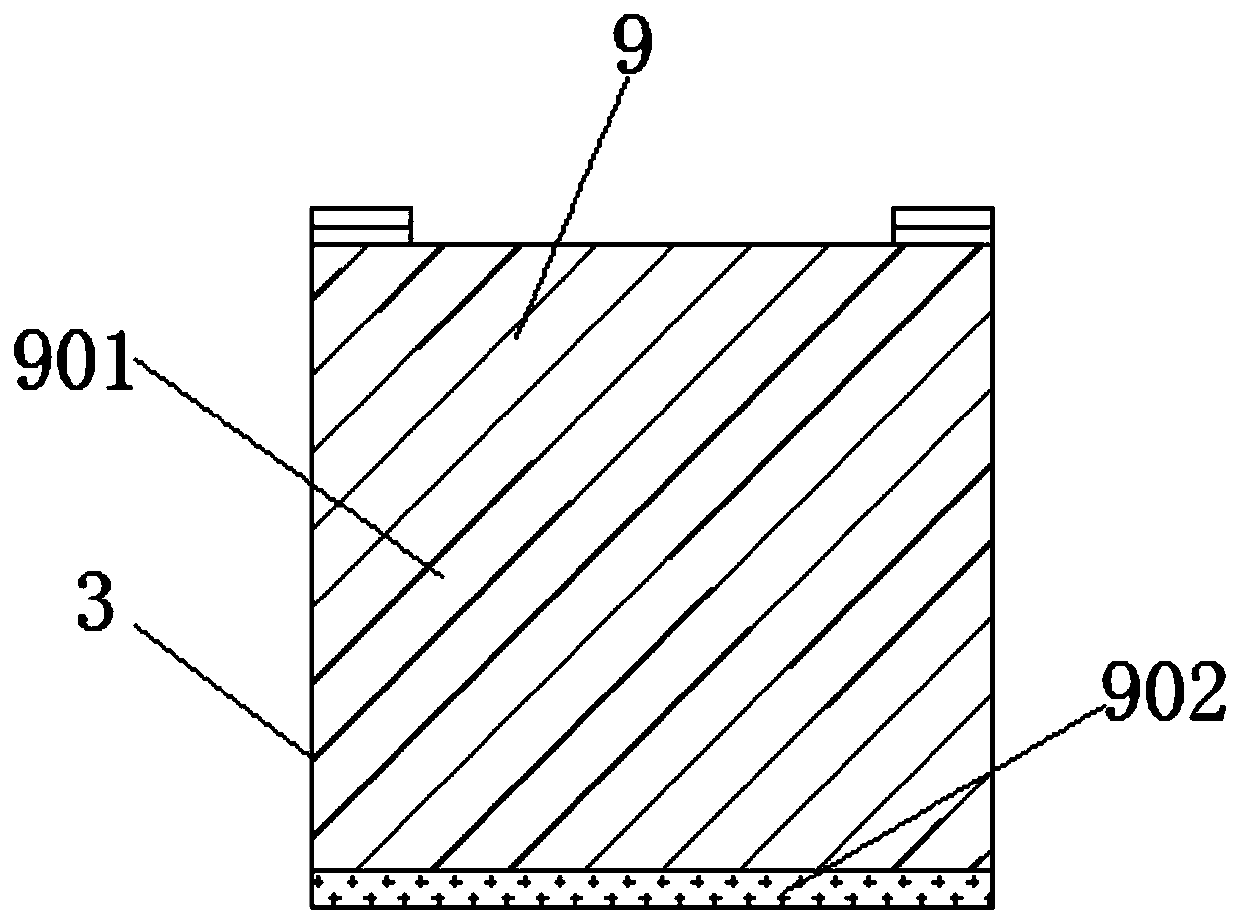

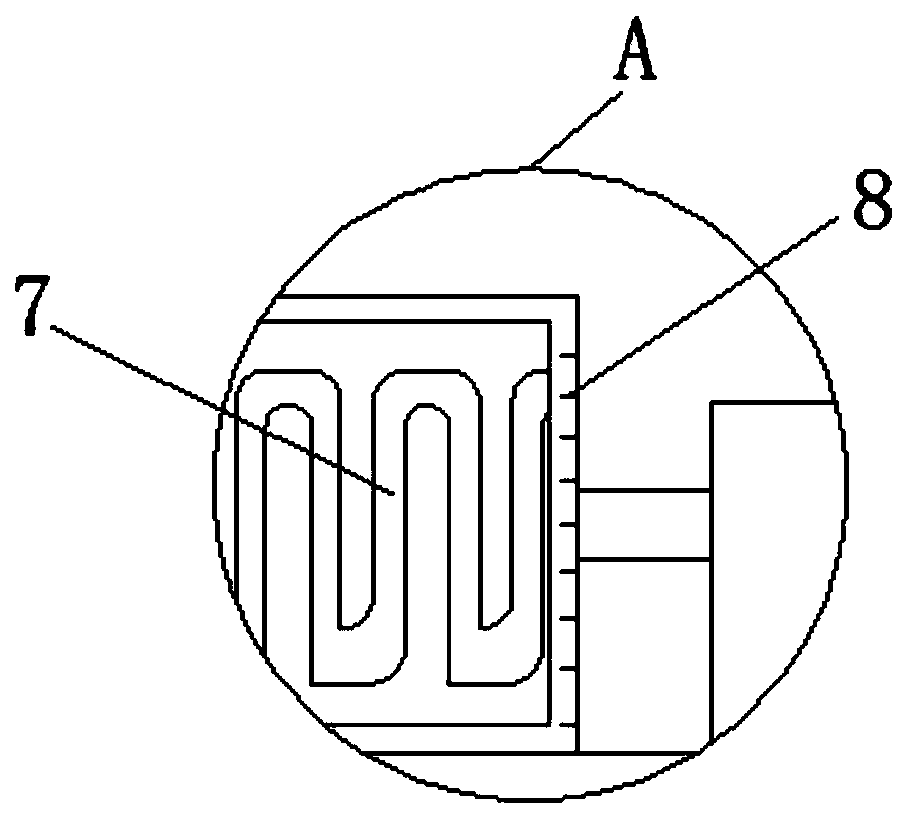

[0033] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 It is a schematic diagram of the overall structure of a construction device for underwater grouting; figure 2 It is a schematic diagram of the structure of the opening and closing mechanism when viewed from above; image 3 It is a schematic diagram of the enlarged structure at A; Figure 4 Schematic diagram of the enlarged structure at B. A construction device for underwater grouting, comprising a load plate 1, a stirring tank 2, a feed port 3, a stirring mechanism 4, a stirring shaft 401, a stirring paddle 402, a motor 403, a water pump 5, a water tank 6, a heating pipe 7, and a scale line 8. Opening and closing mechanism 9, cover plate 901, magnetic strip 1 902, magnetic strip 2 903, feeding pump 10, grouting pipe 11, fixing mechanism 12, fixing plate 1201, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com