A small dredging device with hydropower dual energy supply

A dredging device and energy supply technology, which is applied in mechanically driven excavators/dredgers, construction, earthmoving machines/shovels, etc. problems such as poor effect, to achieve the effect of facilitating later transportation, improving the dredging effect, and reducing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

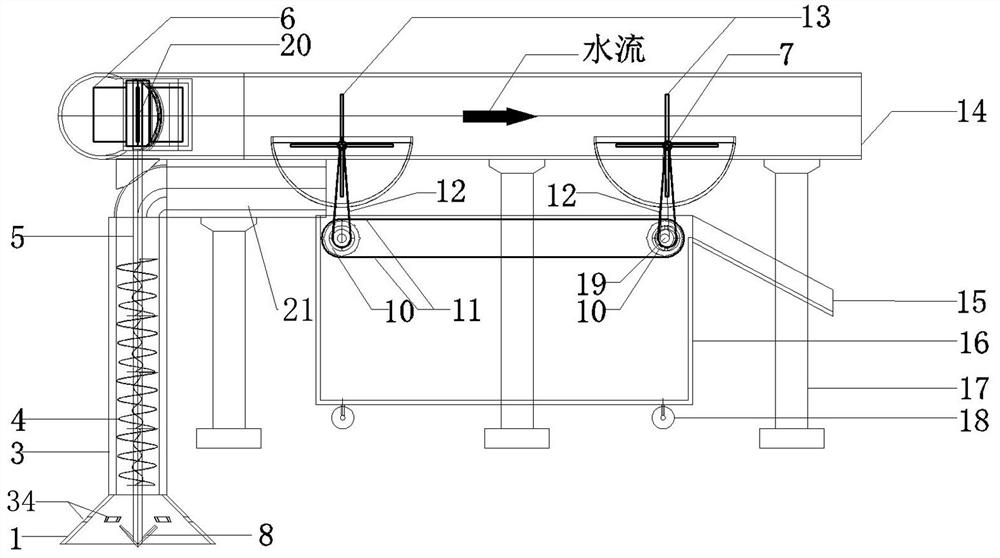

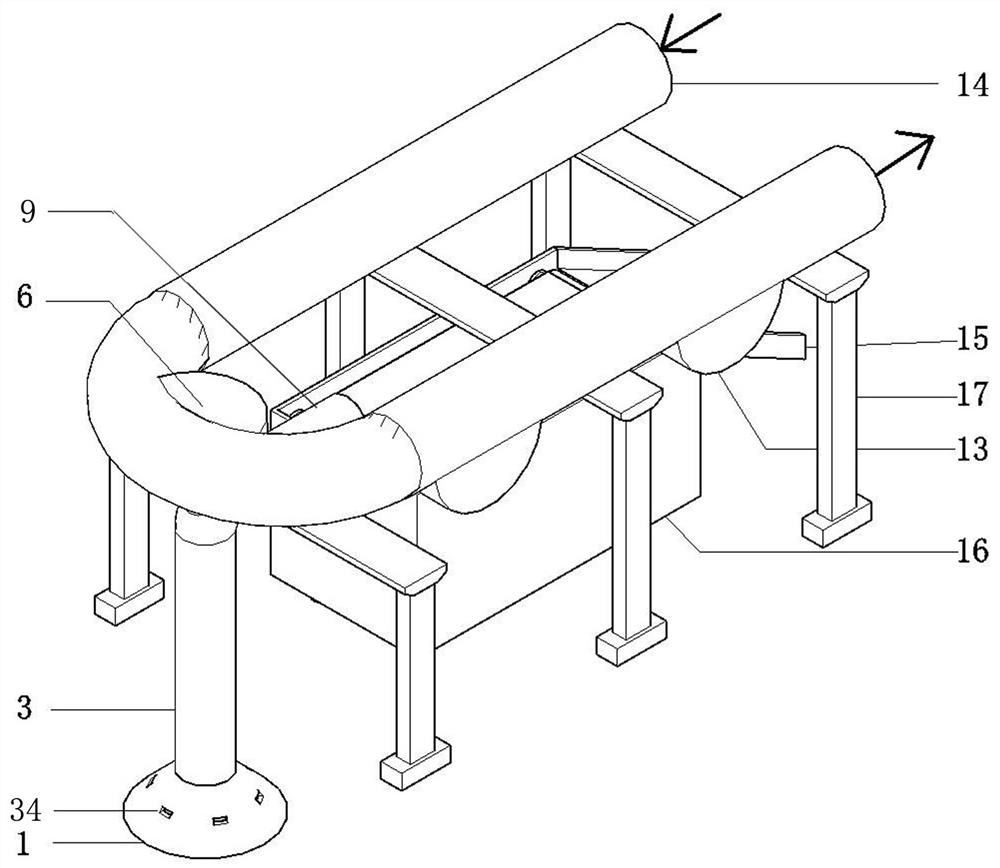

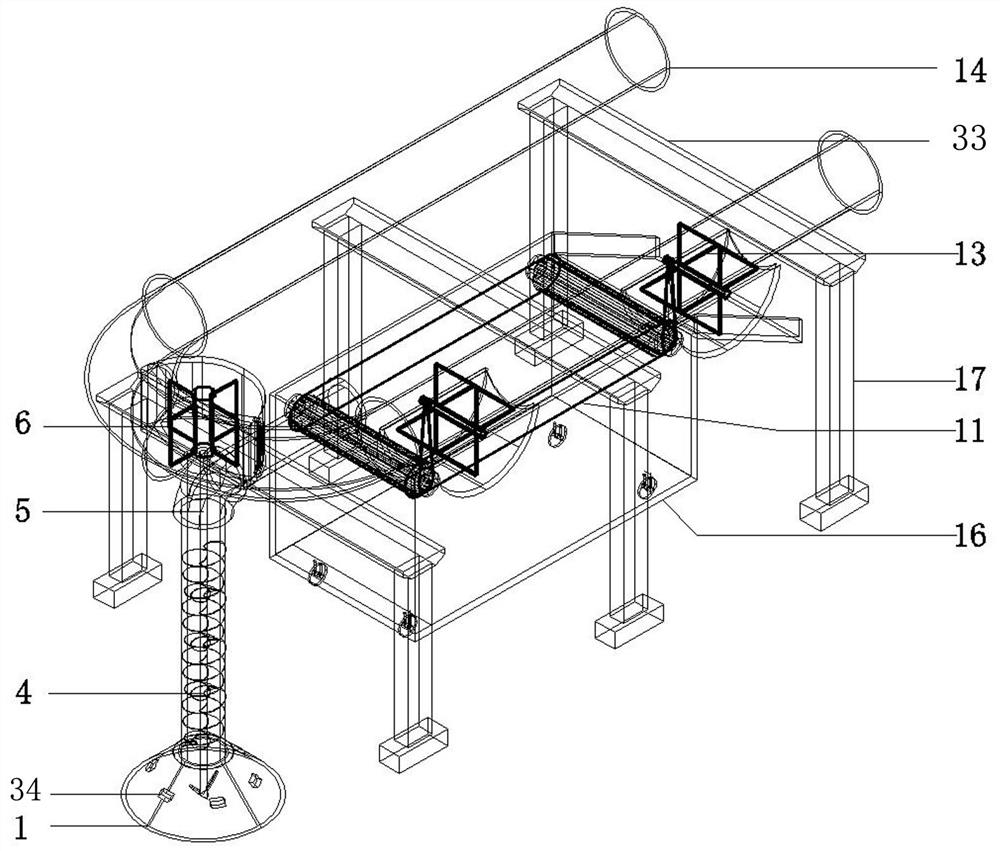

[0027] Embodiment 1: This embodiment provides a small-scale dredging device with dual power supply of water and electricity, such as Figure 1-4 As shown, the small dredging device includes a fixed bracket 17, a water delivery pipeline 2, a silt suction mechanism and a sludge treatment mechanism, the water delivery pipeline 2 is provided with a water collection box 16, the bottom of the water collection box is provided with a drain outlet, and the bottom is provided with Roller 18; Wherein fixed bracket comprises support leg 32 and lateral support plate 33, and water pipeline is U-shaped pipeline, and it is horizontally placed on the horizontal support plate 33 of fixed bracket 17; Water pipeline 2 comprises three parts, is water inlet pipe respectively 29. The connecting pipe 30 and the outlet pipe 31. The connecting pipe 30 is the front end of the entire water delivery pipe 2. A vertical water wheel installation cavity 22 is provided in the middle of the connecting pipe 30. T...

Embodiment 2

[0033] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that, as Figure 5 As shown, in order to further ensure the silt suction effect of the silt suction mechanism, a drive gear 24 with a small wheel diameter is provided under the rotating shaft 20 of the vertical impeller 6, and a driven gear 25 with a large wheel diameter is meshed on the side of the drive gear. The transmission shaft 5 is coaxially connected with the driven gear 25, and the transmission ratio of the driving gear and the driven gear is controlled between 1:5-1:10. When the vertical water wheel 6 is impacted and rotated by the water flow, the driving gear of the small wheel diameter drives the driven gear of the large wheel diameter to drive the transmission shaft to rotate, which can increase the agitation force of the transmission shaft, enhance the agitation effect of the transmission shaft, and ensure the suction The silt in the mud hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com