Honeycomb composite suspended ceiling board and mounting method thereof

A ceiling panel and honeycomb technology, applied in the field of honeycomb composite ceiling panel and its installation, can solve the problems of large variation range of surface structure strength of ceiling panel, loss of fixed installation performance of ceiling panel, unusable aluminum honeycomb panel, etc., and achieve structural strength. The effect of small change interval, light weight and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

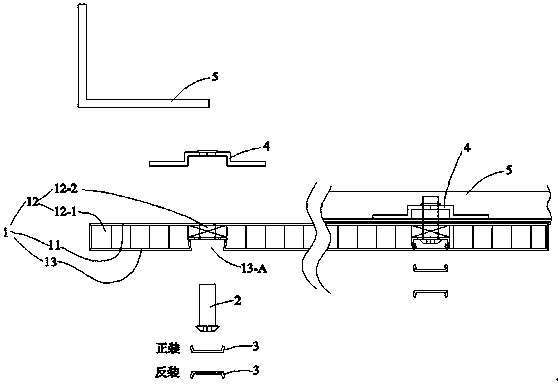

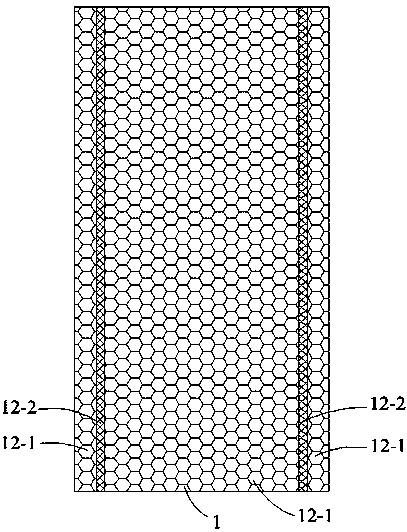

[0042] refer to figure 1 , figure 2 , image 3 , a honeycomb composite ceiling panel, including a ceiling panel 1, the ceiling panel 1 is a three-layer structure composed of a top panel 11, a middle layer 12 and a bottom panel 13, the top panel 11 and the bottom panel 13 are metal sheets, and high-quality alloy aluminum panels can be selected Or a high manganese alloy aluminum plate is used as the base material of the top plate 11 and the bottom plate 13, and most of the middle layer 12 is set as a honeycomb structure 12-1. The forming of the skin is fully automatic machine folding, and the front and back skins are tightly occluded at the installation edge.

[0043]The middle layer 12 of the suspended ceiling board 1 that is 5-15 cm away from the two long sides is set as a mounting part 12-2, and the mounting part 12-2 is in the shape of a strip parallel to the long sides, and its end face is square, with a width of 1.5-2.5 cm, the mounting part 12 - 2 and the honeycomb st...

Embodiment example 2

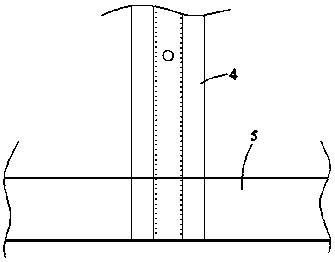

[0050] refer to Figure 4 , the ceiling plate 11 corresponding to the mounting part 12-2 is recessed inwardly to form a groove 11-A, and the depth of the groove 11-A is 1 / 3-1 of the thickness of the ceiling plate with the honeycomb structure 12-1 / 2, that is, the thickness of the ceiling board 1 with the mounting part 12-2 is compressed to 1 / 2-2 / 3.

Embodiment example 3

[0052] refer to Figure 5 The top plate 11 and the bottom plate 13 of the corresponding mounting part 12-2 of the suspended ceiling plate are both inwardly recessed to form a groove 11-A and a groove 13-A, and the groove 11-A, the groove 13-A The depth is 1 / 6-1 / 4 of the thickness of the ceiling panel with the honeycomb structure 12-1, that is, the thickness of the ceiling panel with the mounting part 12-2 is compressed to 1 / 2-2 / 3. The groove 13-A is a dovetail groove, and an edge-sealing decorative strip is provided in the groove 13-A to close the notch, and the edge-sealing decorative strip can be installed frontally or reversely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com