Advanced support structure for shallow buried and dark excavated tunnel in water-rich miscellaneous fill area and construction method

A technology of shallow buried excavation and advanced support, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as instability, loose settlement of miscellaneous fill structures, etc., to improve bearing capacity and reduce surface subsidence As well as the risk of roof fall and the effect of improving safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

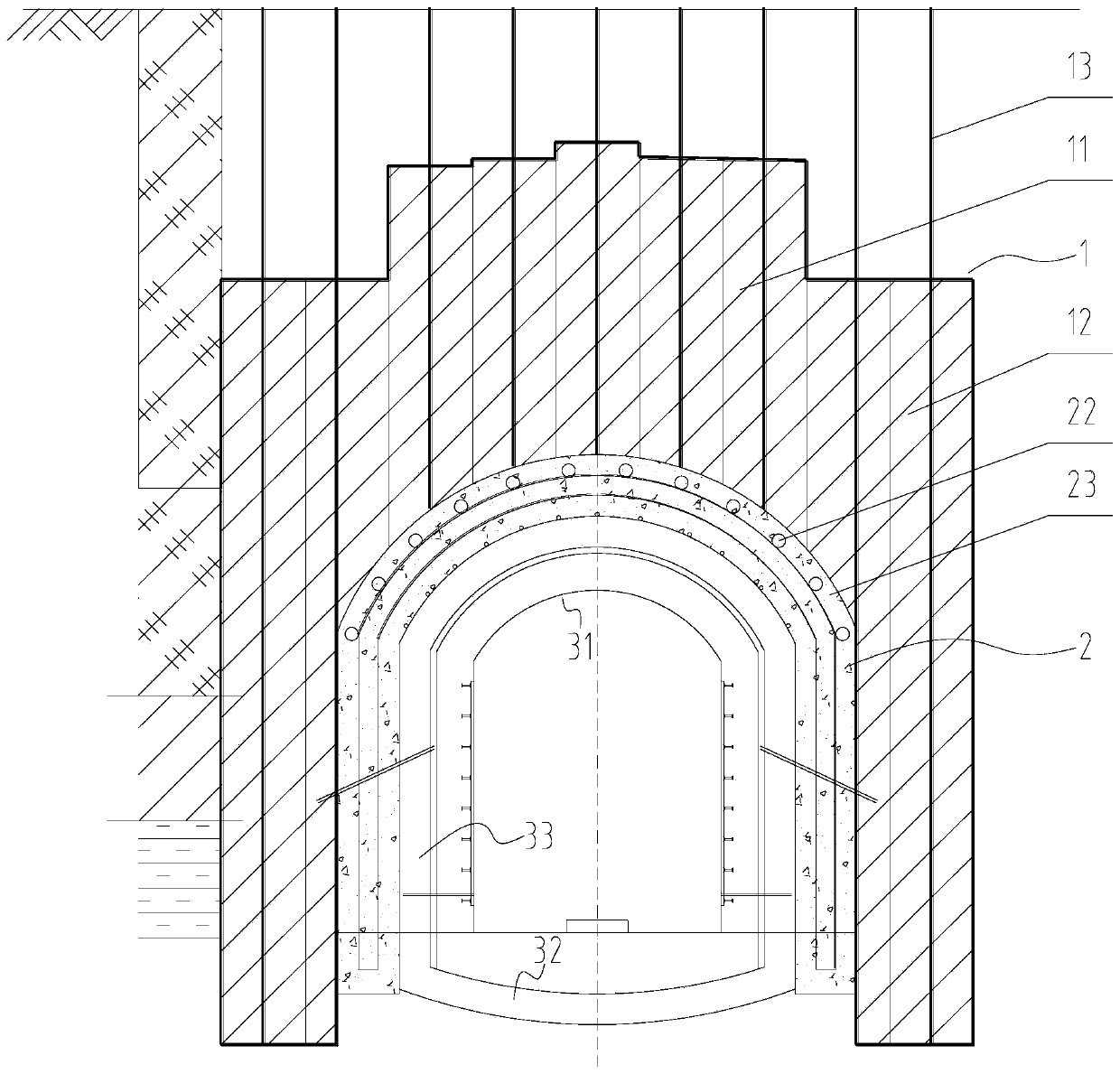

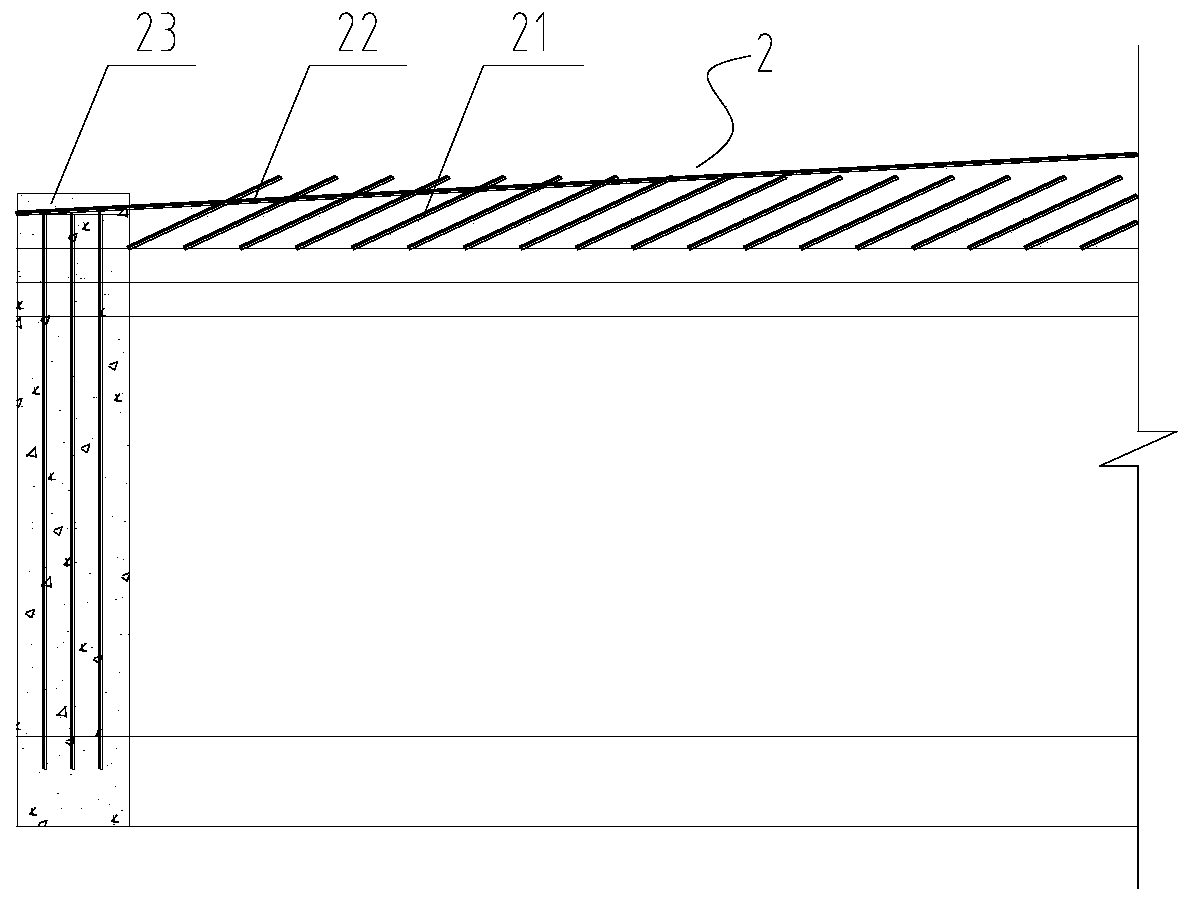

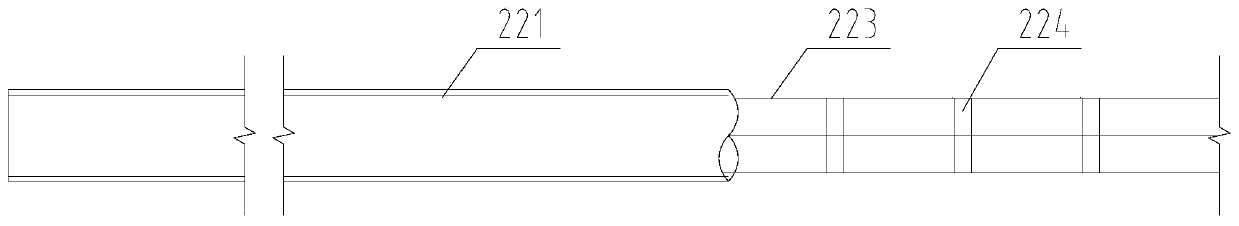

[0026] Advanced support structure for shallow buried tunnels in water-rich miscellaneous fill areas, such as figure 1 and figure 2 As shown, it includes a cave body advance support structure 2 for the tunnel body and a surface reinforcement structure 1 outside the tunnel; the cave body advance support structure 2 includes a small grouting conduit 21 and an advance large pipe shed 22, so The advanced large pipe shed 22 runs through the whole line from one end of the tunnel to the other end along the longitudinal direction of the tunnel; the small grouting conduits 21 are arranged in rows on the top of the tunnel along the longitudinal direction of the tunnel from one end to the other end of the tunnel; vertically, the surface reinforcement structure 1 is arranged in the surrounding rock above the large pipe shed 22 in advance.

[0027] The advanced su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com