Non-explosive simulated explosive roll dynamic load loading device and test method thereof

A technology of loading device and dynamic load, which is applied to weapon accessories, blasting cylinders, offensive equipment, etc., can solve the problems of limited detonation energy, complicated test operation, destructive and dangerous detonation process, etc., to achieve convenient operation, controllable time, The effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

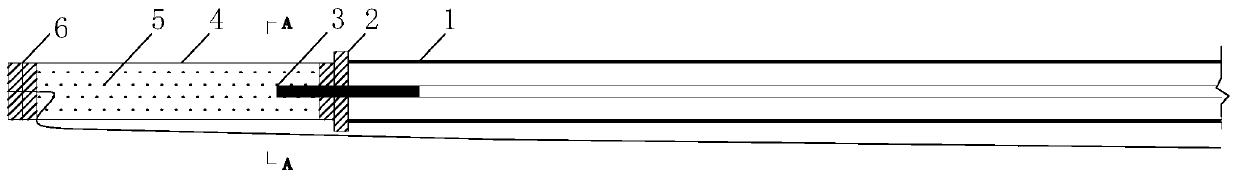

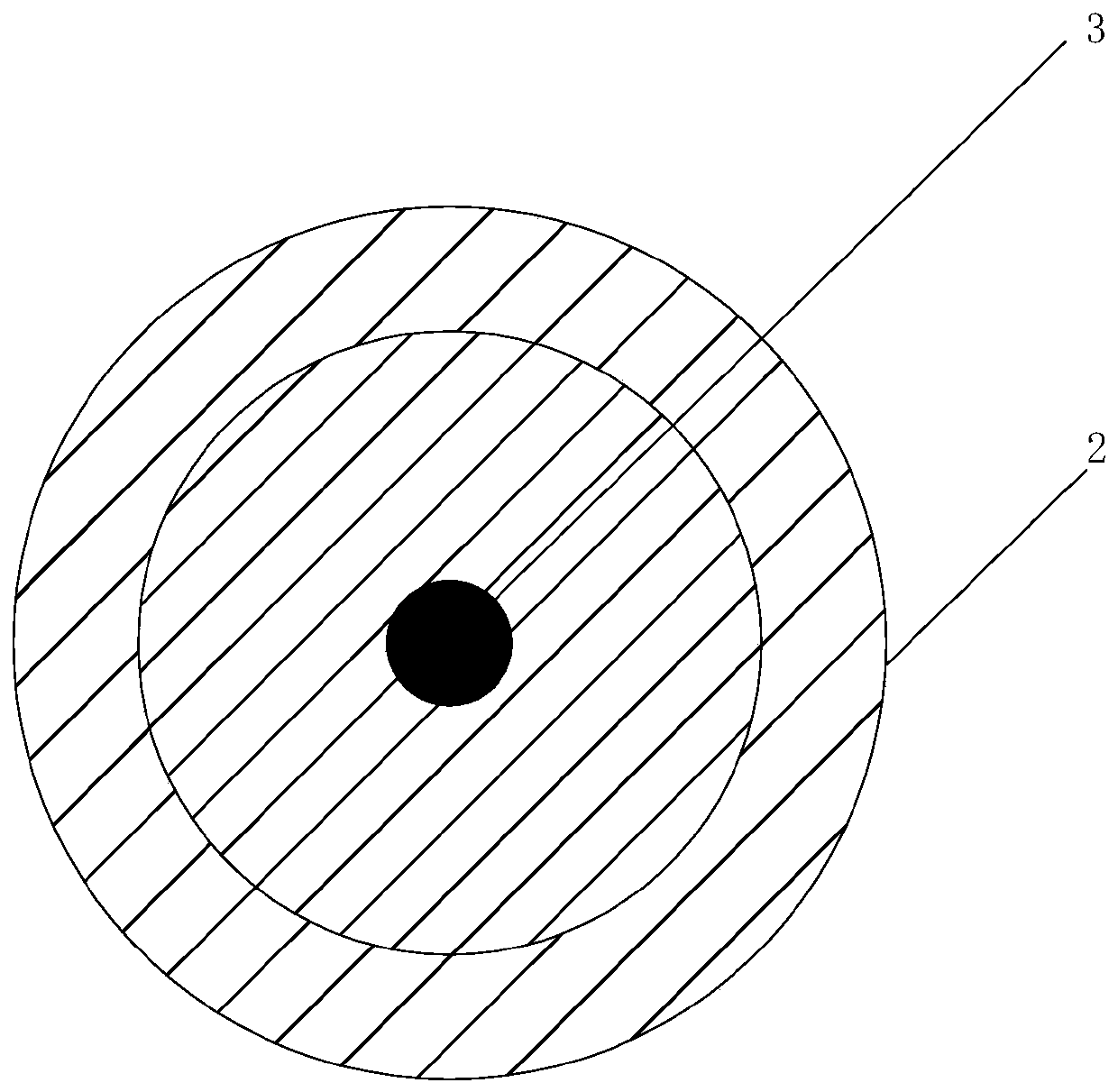

[0026] refer to figure 1 and figure 2 , a non-explosive simulated explosive rolling load loading device, including PVC pipe 1, saturated brine 5, PC pipe 4, cylindrical rubber cap 6 with metal wires, T-shaped rubber cap 2 with holes, portable shock source electric spark discharge head 3. The PVC pipe 1 has an outer diameter of 2.4cm, an inner diameter of 2.0cm, and a length of 2.5m. It is used as a safety lever to protect the high-voltage insulated wires connected to the spark discharge head, and to avoid contact between the human body and the high-voltage insulated wires of the spark discharge. Saturated brine 5 is prepared by using purified water at 20°C and iodized salt at a ratio of less than 100:36. The PC pipe 4 has an outer diameter of 2.2 cm, an inner diameter of 2.0 cm, and a length of 10 cm, and is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com