Precise metering method and metering device for fluid delivery system based on artificial intelligence

A technology of a fluid conveying system and a metering method, applied in the field of precise metering method and metering device of a fluid conveying system based on artificial intelligence, can solve the problems of non-selective installation, inadequate metering work, medium leakage, etc., to reduce installation size and cost, improve operational safety, and improve the effect of metering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

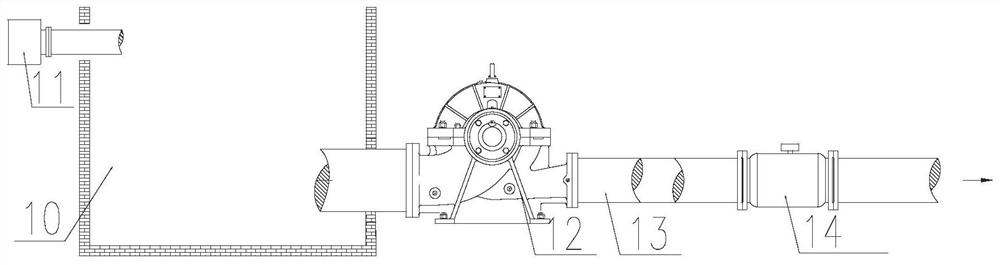

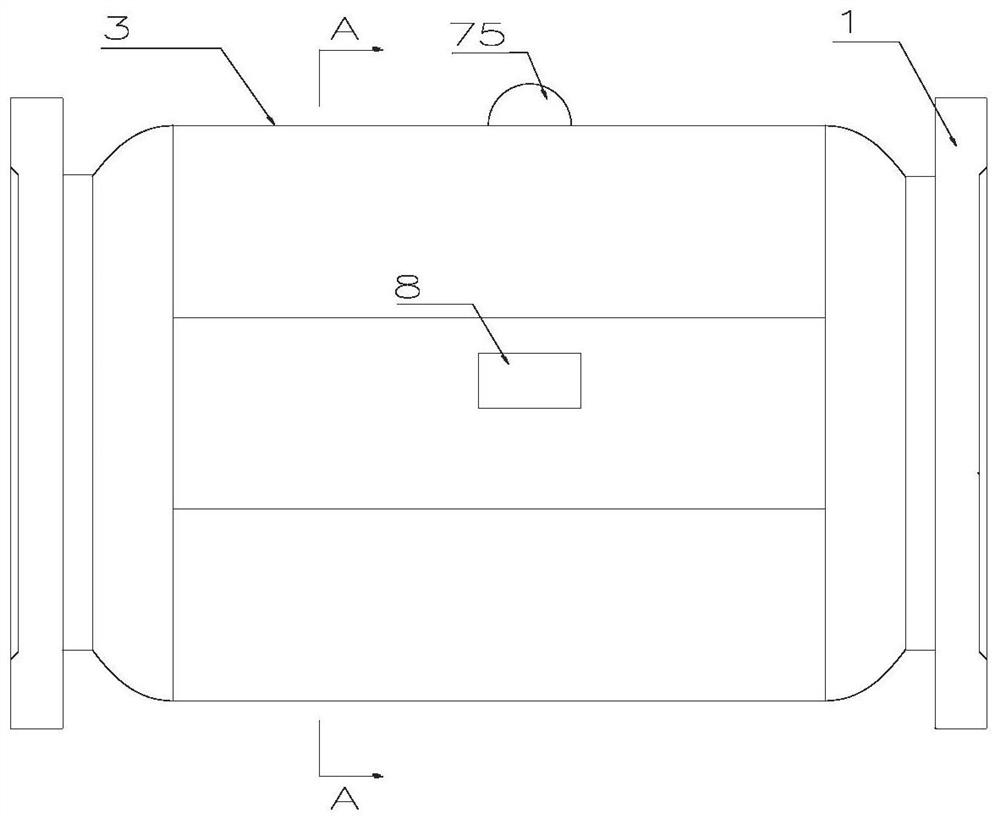

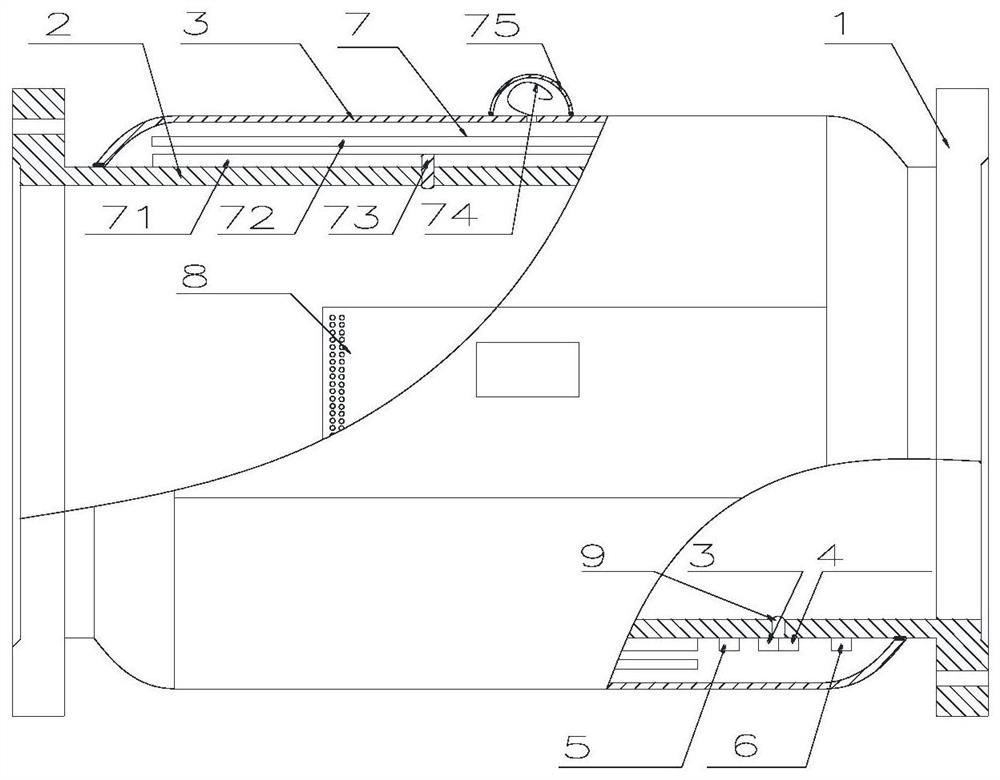

[0056] The following will combine Figure 1-Figure 8 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0057] The flow rate Q in the present invention refers to the volumetric flow rate. In the same fluid system, after a fluid delivery system is established and operated, the hardware or flow-through components will not change. Wet parts refer to the surface of the object in contact with the conveying medium. The invention is suitable for an open fluid system, that is, the conveying medium is in contact with the external environment, and the pressure of the external environment does not change. In the present invention, the fluid delivery system is referred to as the fluid system for short. This type of fluid system accounts for a large part, such as: tap water system, industrial cooling water system, fresh air system, boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com