Electromagnetic ultrasonic longitudinal guided wave probe of an interpolation type full-coil structure and nondestructive testing method

An electromagnetic ultrasonic and ultrasonic guided wave technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problem of low probe conversion efficiency and signal-to-noise ratio Problems such as unreachable probes and uneven magnetic field distribution achieve the effects of improved detection capability, low manufacturing cost, and strong signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

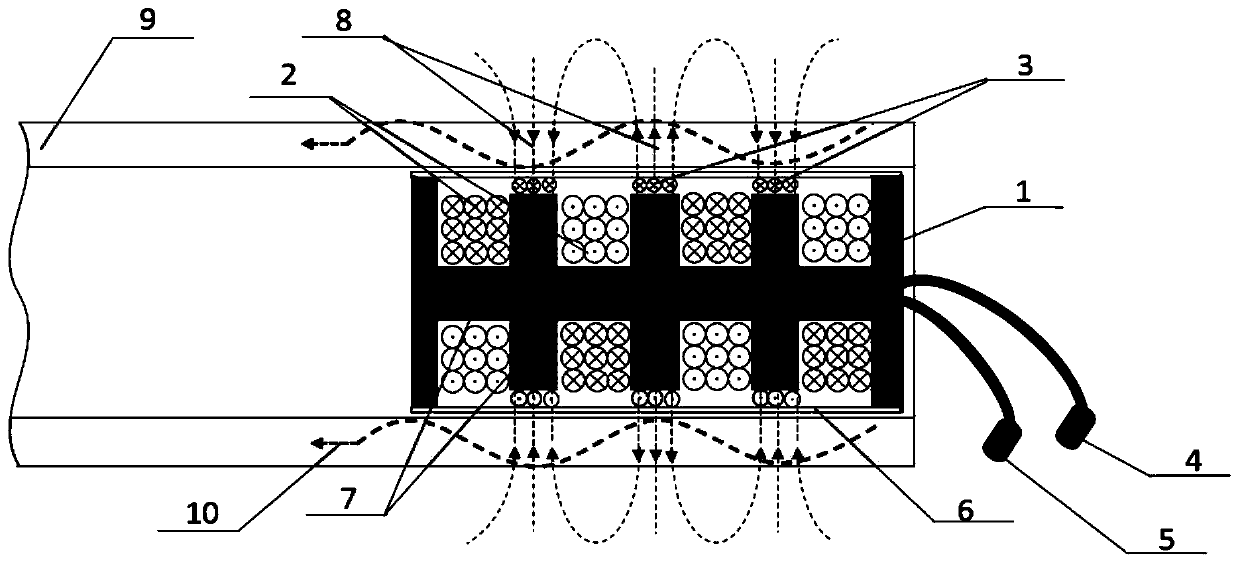

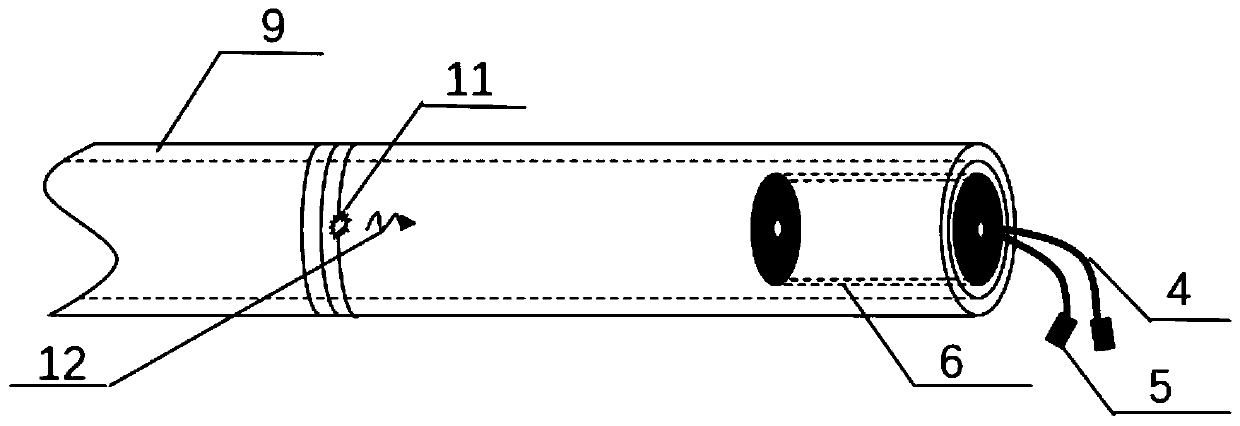

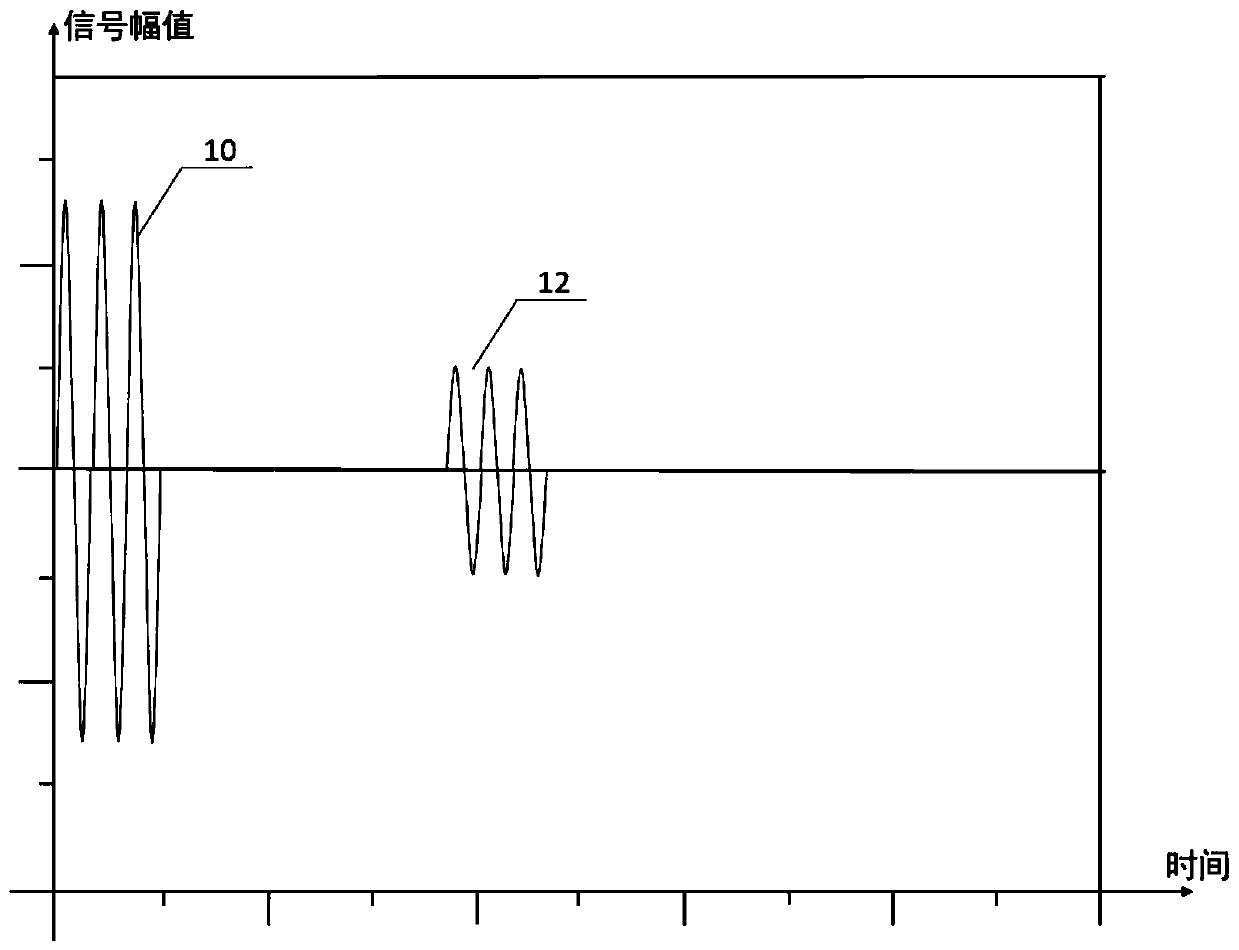

[0019] Embodiment: combine below figure 2 , image 3 The application of the probe of the present invention is further described. The invention proposes an electromagnetic ultrasonic longitudinal guided wave probe with an interpolated full-coil structure, which is used for detecting pipe wall defects of non-ferromagnetic small-diameter metal pipes. When testing, first directly insert the interpolated full-coil structure electromagnetic ultrasonic longitudinal waveguide probe such as figure 2 The shown insertion is at one end of the pipe to be tested 9 , and there is no need for complete contact and liquid couplant between the probe and the pipe wall of the pipe to be tested 9 . The interpolated electromagnetic ultrasonic longitudinal guided wave probe excites the longitudinal mode guided wave propagating along the axial direction of the pipe on the pipe wall of the tested pipe 9. image 3 The position and size of the defect can be evaluated by analyzing the time and amplit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com