Multi-channel laser galvanometer motion control system with multiple connection modes

A motion control system, laser galvanometer technology, applied in general control systems, control/adjustment systems, program control, etc., can solve the problems of limited working range of galvanometer processing equipment, inconvenient switching of motion modes, etc., to simplify system design and The effect of the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

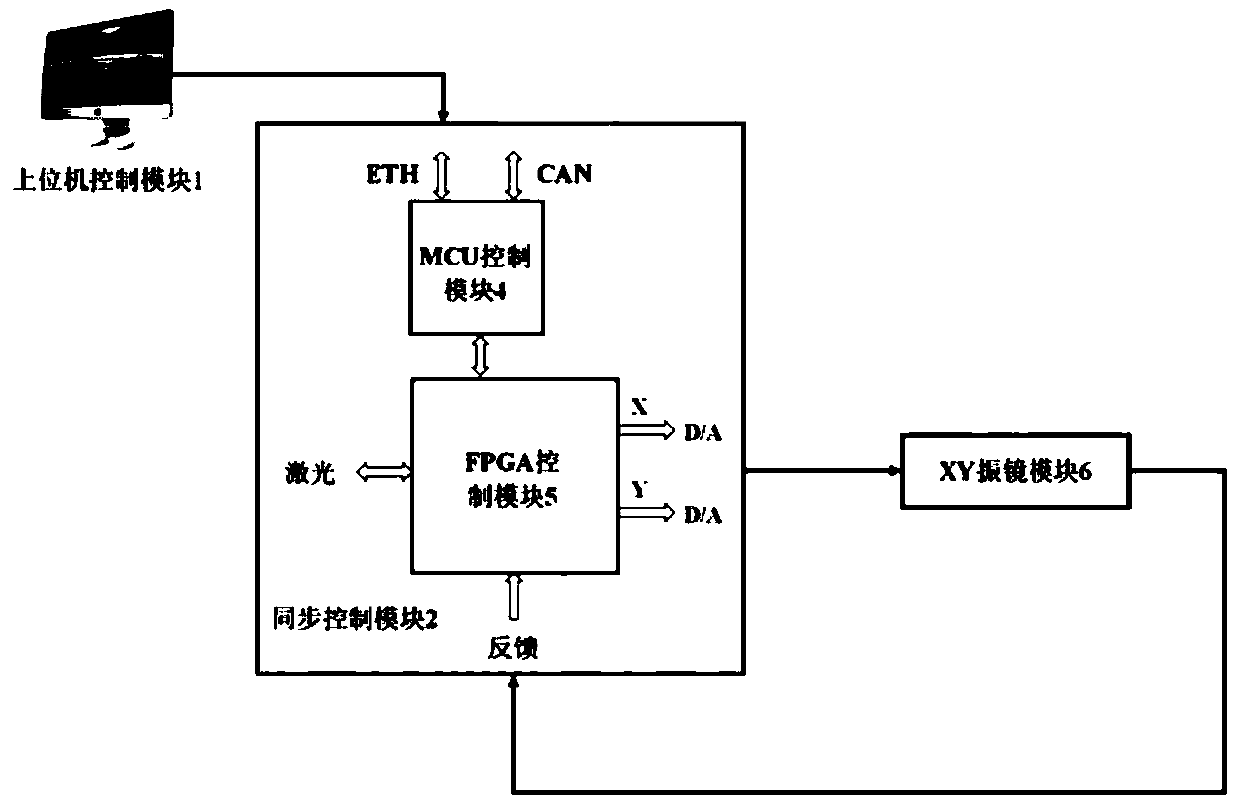

[0019] Such as figure 2 As shown, a dual-channel motion control scheme of a multi-channel laser galvanometer motion control system with multiple connection modes includes a host computer control module 1, a synchronization control module 2 and a servo drive module 3. Synchronous control module 2 can be divided into MCU control module 4 and FPGA control module 5; the servo drive module is now XY galvanometer module 6, including galvanometer XY dual-axis channels. The host computer control module 1 sends trajectory commands and receives feedback signals to the MCU control module 4 in the synchronization control module 2 through the ETH Ethernet communication interface; the MCU control module 4 exchanges servo control input and output signals with the FPGA control module 5 through the SPI interface; The FPGA control module 5 implements closed-loop control through a custom control algorithm, and communicates with the servo drive module through a D / A interface.

[0020] The host comp...

Embodiment 2

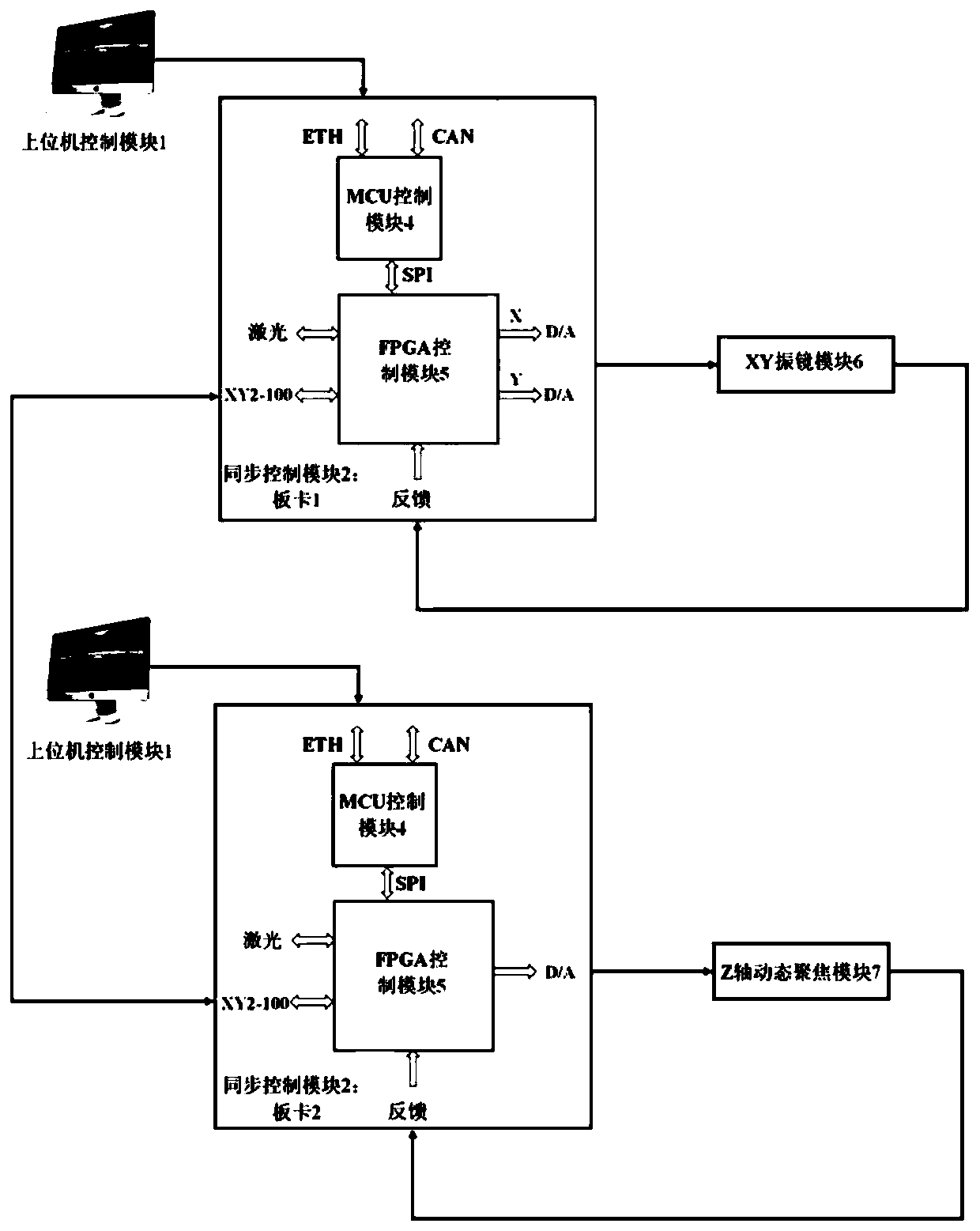

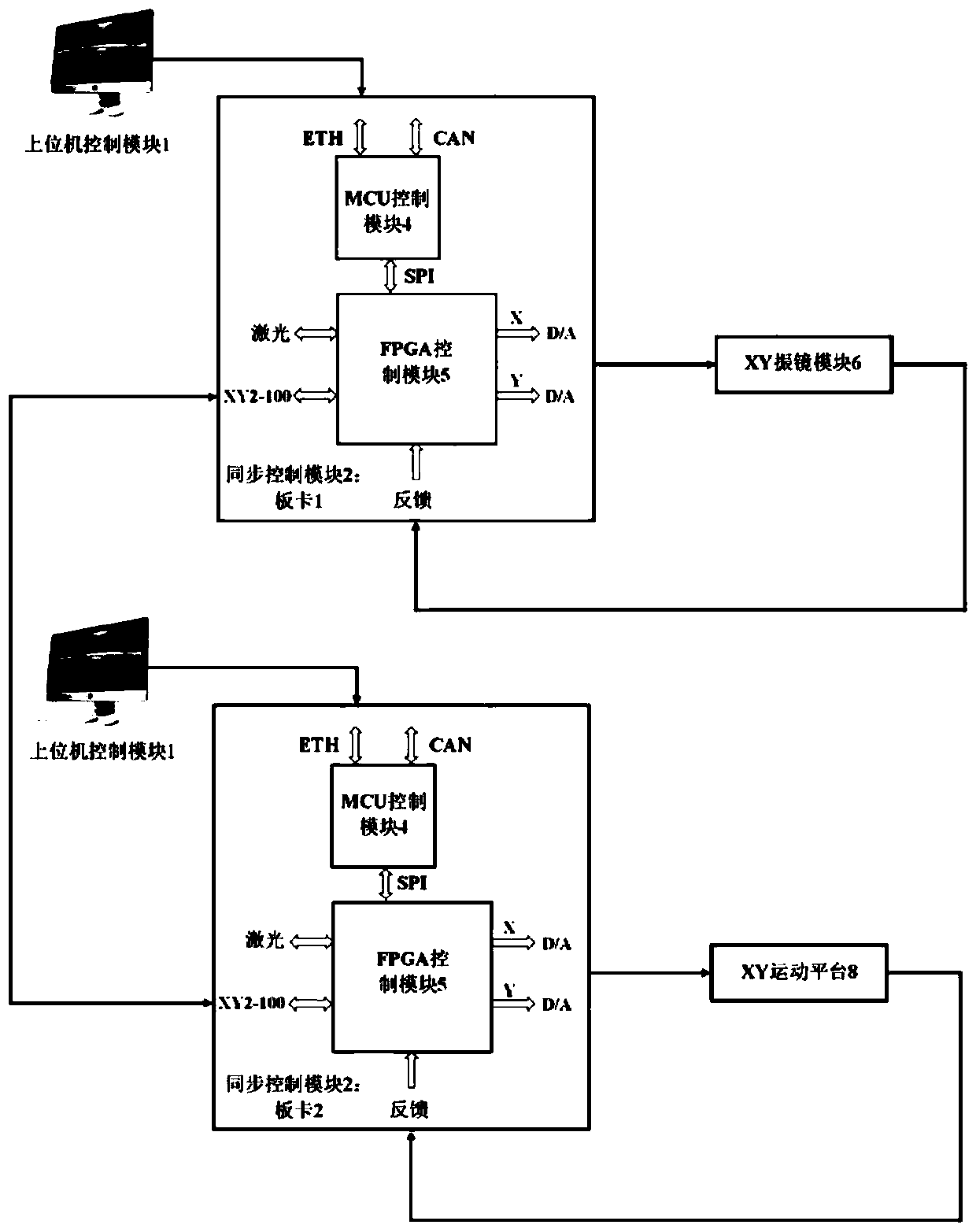

[0026] Such as figure 2 As shown, a three-channel motion control scheme of a multi-channel laser galvanometer motion control system with multiple connection modes includes a host computer control module 1, a synchronization control module 2 and a servo drive module 3. Synchronous control module 2 can be divided into MCU control module 4 and FPGA control module 5; the servo drive module is now XY galvanometer module 6 and Z-axis dynamic focus module 7, including galvanometer XY dual-axis channels and Z-axis channels. The host computer control module 1 sends trajectory commands and receives feedback signals to the MCU control module 4 in the synchronization control module 2 through the ETH Ethernet communication interface; the MCU control module 4 exchanges servo control input and output signals with the FPGA control module 5 through the SPI interface; FPGA control module 5 realizes closed-loop control through a custom control algorithm, and communicates with the servo drive modu...

Embodiment 3

[0033] Such as image 3 As shown, a four-channel motion control scheme of a multi-channel laser galvanometer motion control system with multiple connection modes includes a host computer control module 1, a synchronization control module 2 and a servo drive module 3. Synchronous control module 2 can be divided into MCU control module 4 and FPGA control module 5; the servo drive module is now XY galvanometer module 6 and XY motion platform 8, including galvanometer XY dual-axis channels and motion platform XY dual-axis channels. The host computer control module 1 sends trajectory commands and receives feedback signals to the MCU control module 4 in the synchronization control module 2 through the ETH Ethernet communication interface; the MCU control module 4 exchanges servo control input and output signals with the FPGA control module 5 through the SPI interface; FPGA control module 5 realizes closed-loop control through a custom control algorithm, and communicates with the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com