Photoetching mask optimization method and device for graphic image joint optimization and electronic equipment

A joint optimization, graphics and image technology, which is applied to the exposure device of the photoplate making process, the photoplate making process of the pattern surface, optics, etc., can solve the problem of unsatisfactory imaging of the mask plate, and achieve the effect of improving the final optimization effect and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

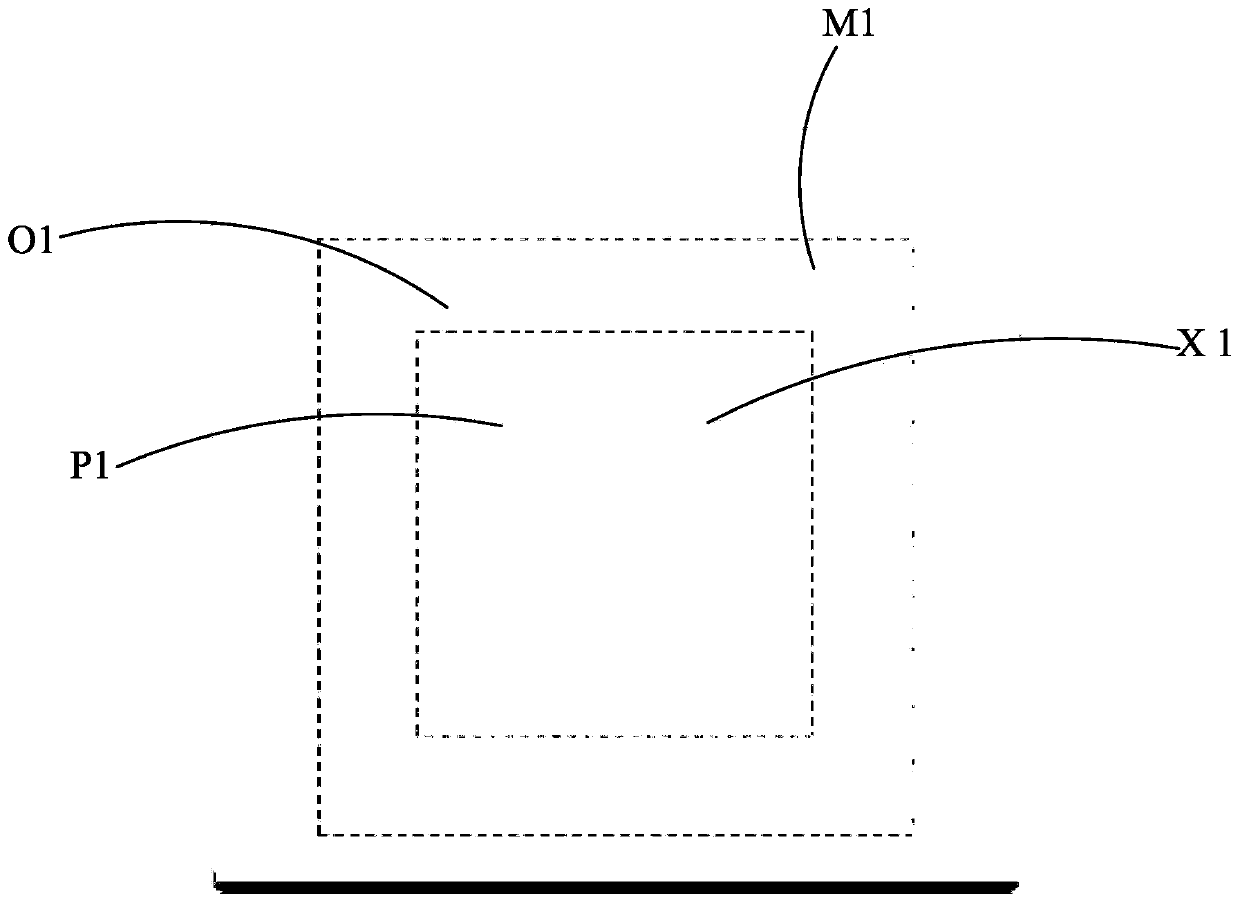

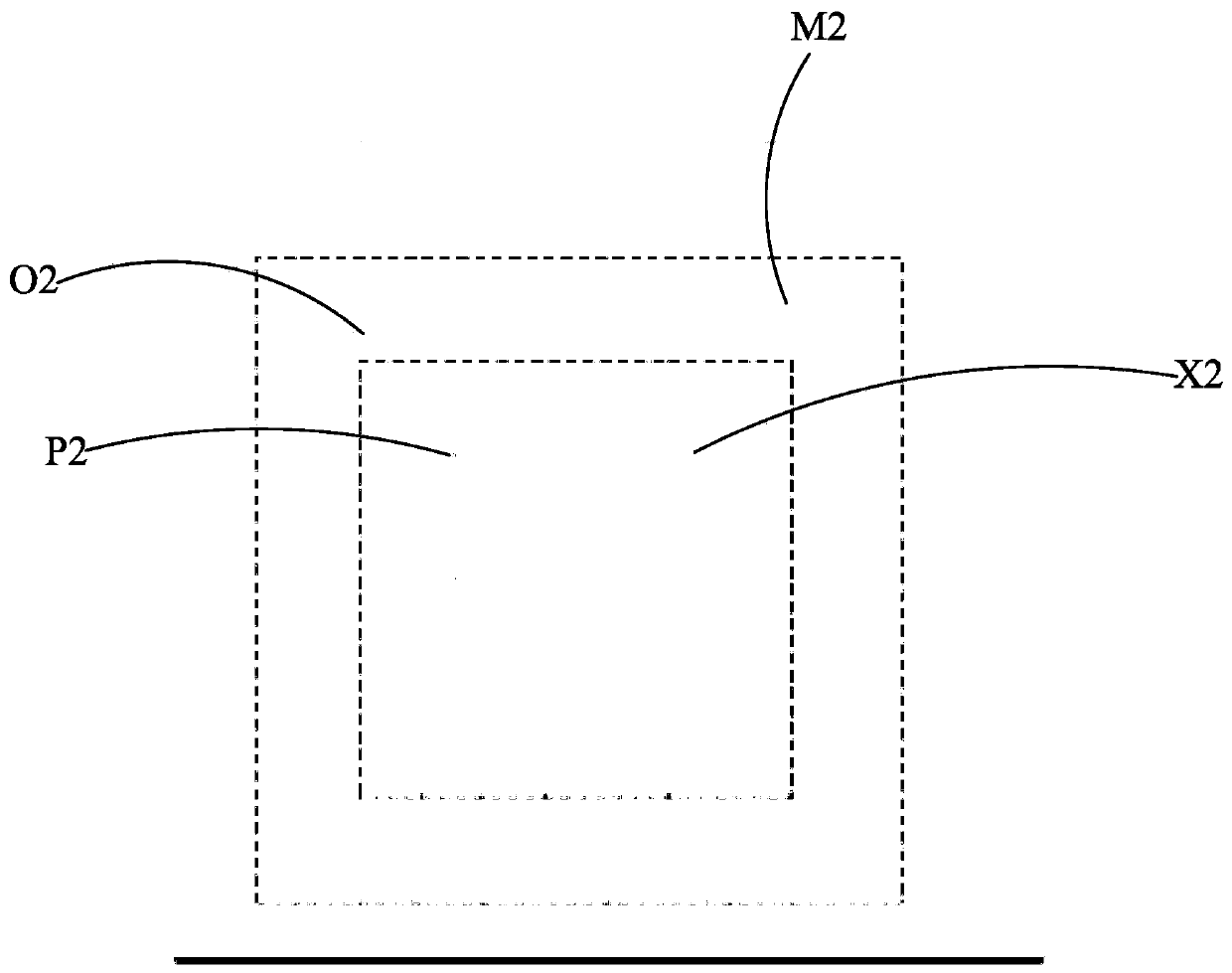

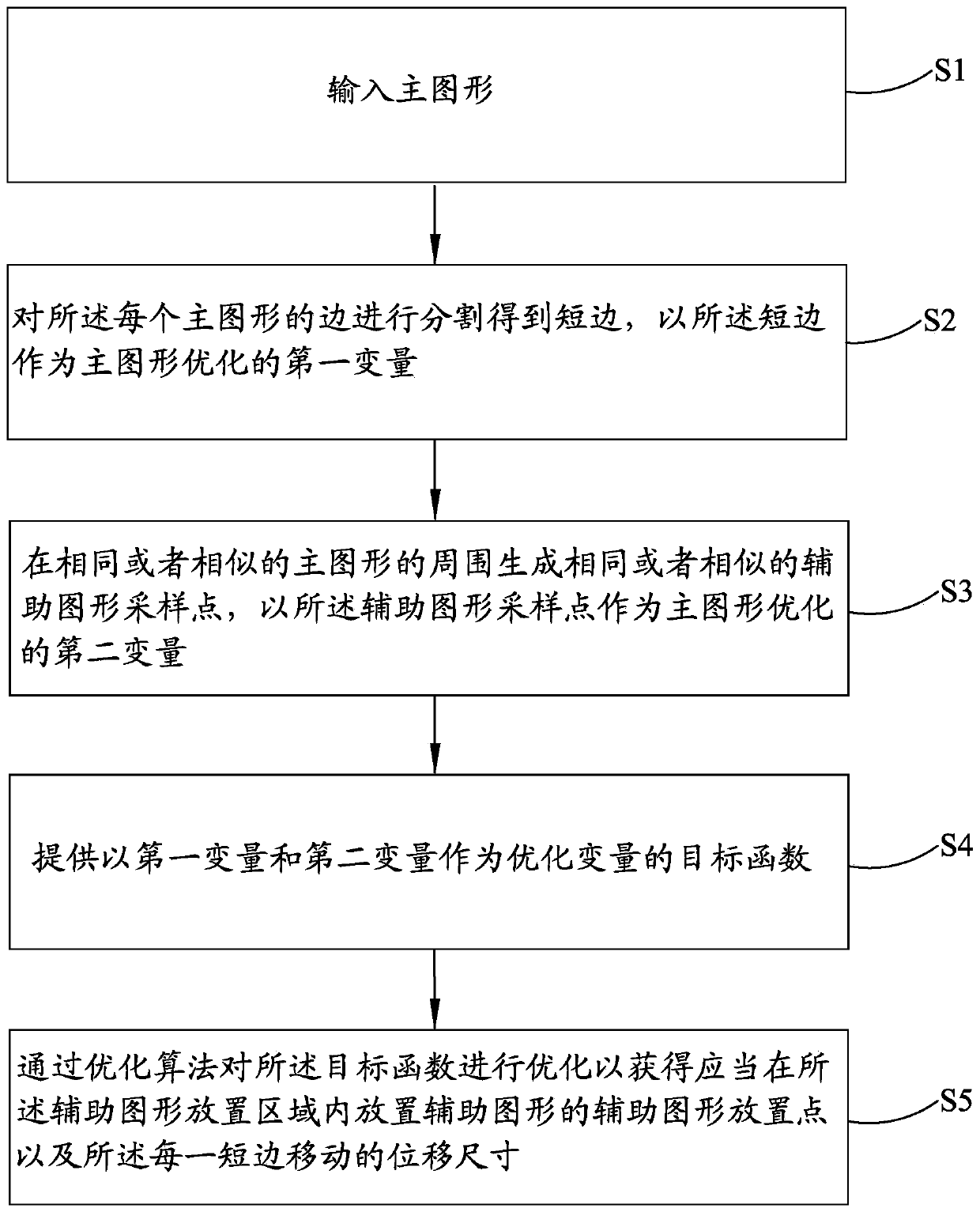

[0051] In order to eliminate the influence of the optical proximity effect, the main pattern on the initial mask is different from the desired lithographic pattern, and the main pattern needs to be processed by Optical Proximity Correction (OPC, Optical Proximity Correction). In the range of 90nm, the line width of the main pattern is even only 1 / 3 of the light wavelength. In addition to the above-mentioned necessary optical proximity correction processing, it is usually necessary to set sub-size auxiliary patterns around the main pattern, that is, sub-resolution auxiliary patterns. Technology (SRAF, Sub-resolution assistant feature). These auxiliary patterns are only set on the photolithographic mask, and the patterns will not be transferred to the semiconductor device after the actual exposure, but only increase the depth of focus adjacent to the main pattern and improve the exposure accuracy. Therefore, in this step, the auxiliary graphics placement area is an area for plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com