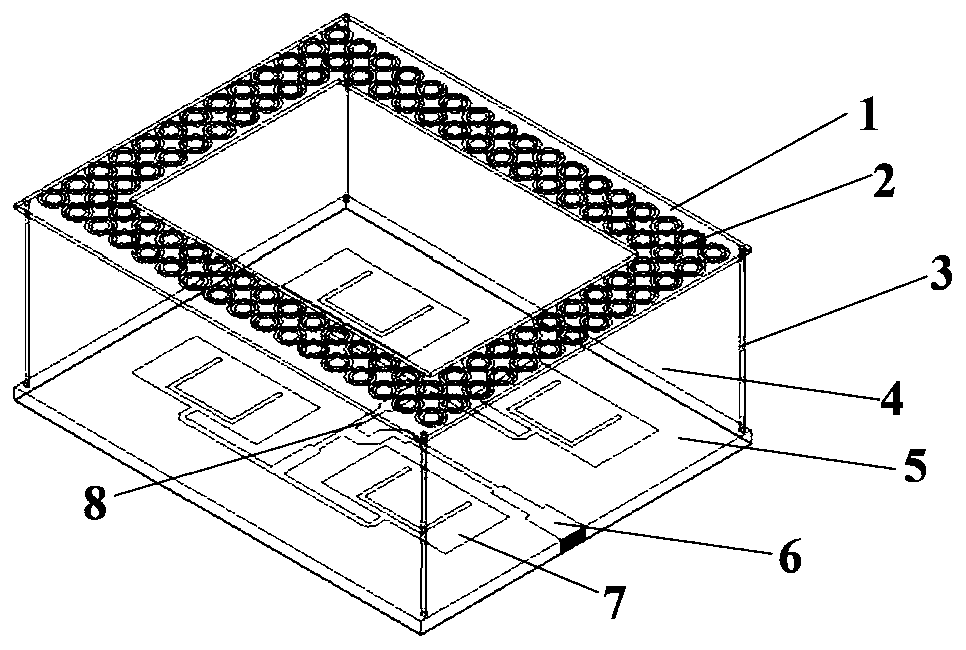

ISM frequency band microstrip array antenna with negative permeability material and manufacturing method

A technology of negative magnetic permeability material and microstrip array, which is applied to devices, antennas, electrical components, etc. that make the antenna work in different bands at the same time, can solve the problems of complex impedance matching network, low bandwidth and gain of microstrip antenna, etc. Reach the effect of reducing half-power beam width, reducing side radiation, and suppressing side radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] First, the specific parameter information in this embodiment is described:

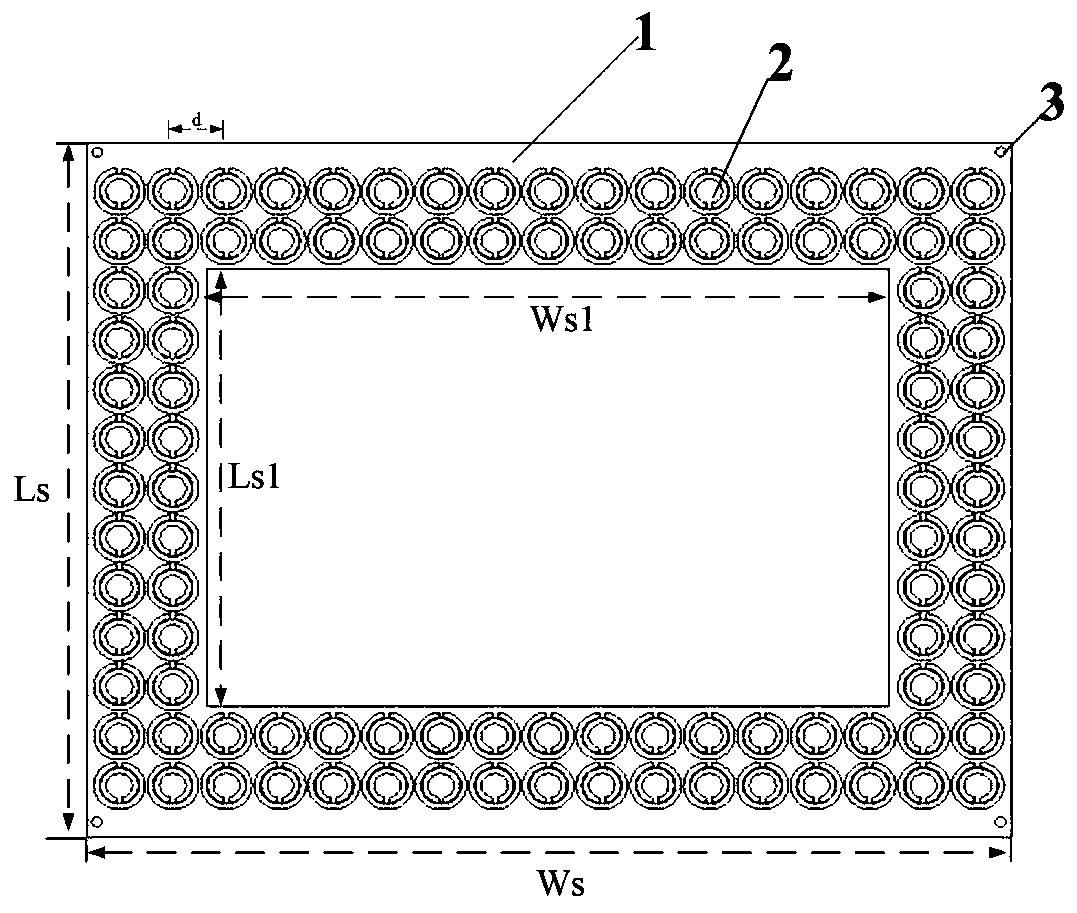

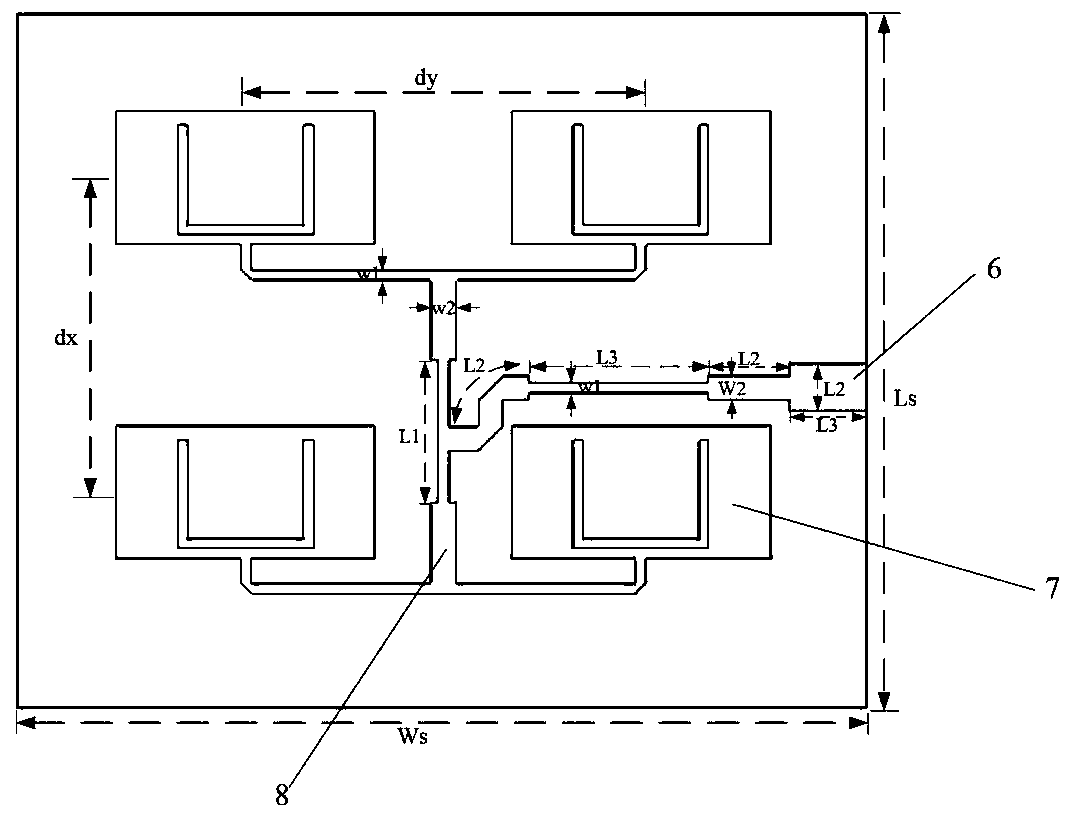

[0061] In this embodiment, four U-shaped slot array antennas 7 are etched, and the feed network 8 is a one-to-four feed network; the length of the first dielectric substrate 1 and the second dielectric substrate 5 are both Ls=143.2 mm, and the width is equal to Ws=175.7mm, the size of the rectangular through hole of the first dielectric substrate is: length Ls1=90.2mm, width Ws1=129.7mm. Wherein the first dielectric substrate 2 and the second dielectric substrate 5 are both epoxy resin (FR4) substrates, the dielectric constant is 4.4, the dielectric loss tangent is tanδ=0.02, and the thicknesses of the first dielectric substrate 2 and the second dielectric substrate 5 are respectively 1.6mm and 5mm.

[0062] See you again image 3 , the length of the rectangular patch of the U-shaped slot array antenna 7 is Lp=27.6mm, and the width is Wp=53.7mm; and along the U-shaped slot opening direction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com