Multi kw class blue laser system

A blue, spectral technology, applied in the direction of lasers, semiconductor lasers, laser components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

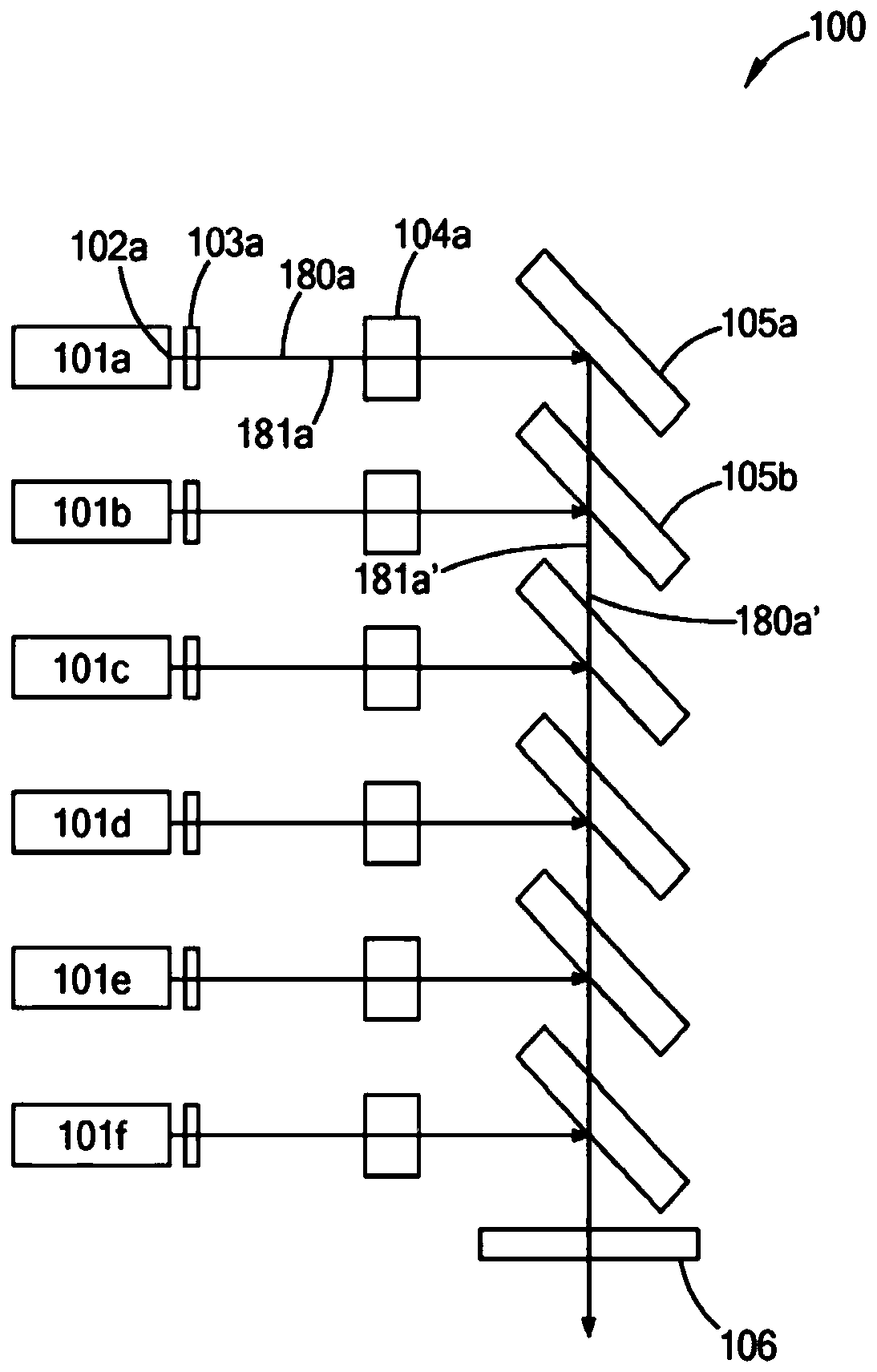

[0087] An embodiment of the assembly (eg, submodule) 100 is a six lens chip substrate (LCOS) structure, and in figure 2 is schematically shown in . In submodule 100, each LCOS has gain elements 101a, 101b, 101c, 101d, 101e, and 101f that each generate a laser beam (eg, 180a) that travels along a beam path (eg, 181a) (the laser beam is in the laser beam path on or coincident with the path of the laser beam, thus indicated by a single arrow). The ability to lock the gain elements 101a-101f as a single element is enhanced by a lower reflectivity (LR) end face coating, preferably on each of the GaN gain elements 101a-101f, such as 102a. Each of the gain elements 101a to 101f has a fast axis collimating lens, such as 103a; and a slow axis collimating lens, such as 104a. Each of the gain elements 101a to 101f has a turning mirror, eg 105a. In this way, the laser beam and the laser beam path respectively extend from the gain element (e.g. 101a) through the fast axis collimator (F...

example 1A

[0093] figure 2 Embodiments of the sub-module also include Zener diodes for reverse bias protection positioned along one or more and all of the beam paths.

example 1B

[0095] figure 2 In an embodiment of the sub-module, the slow axis collimating (SAC) lens 104 is separate from the turning mirror 105 . In one embodiment, the two can be combined by using an off-axis parabolic mirror approach, or the SAC lens can be mounted after the steering mirror, depending on the design goals of the sub-module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com