Boiling-resistant sour and hot beef tallow hotpot condiment and preparation method thereof

A technology of hot pot bottom material and hot and sour butter, which is applied in the food field, can solve the problems of rapid change in acidity and unsustainable sourness, and achieve the effects of slow change in acidity, enhanced acidity, rounded sourness and no sharp sourness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

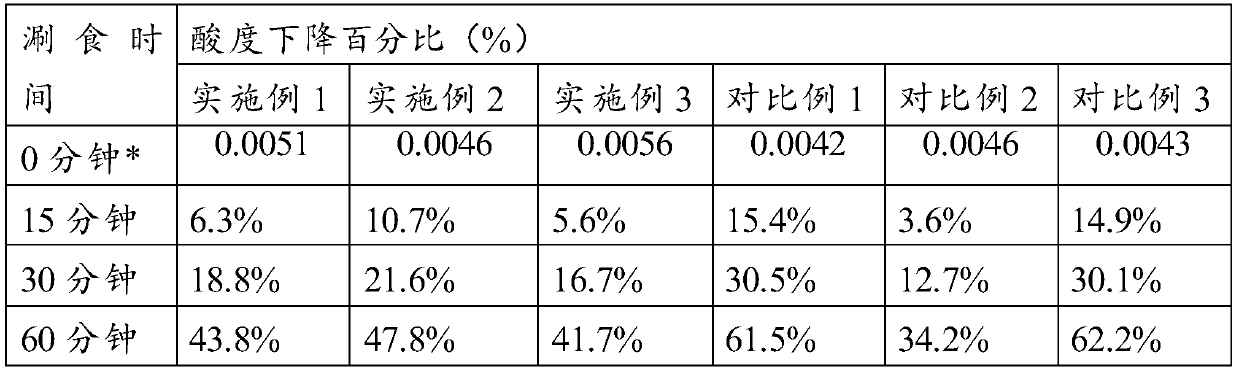

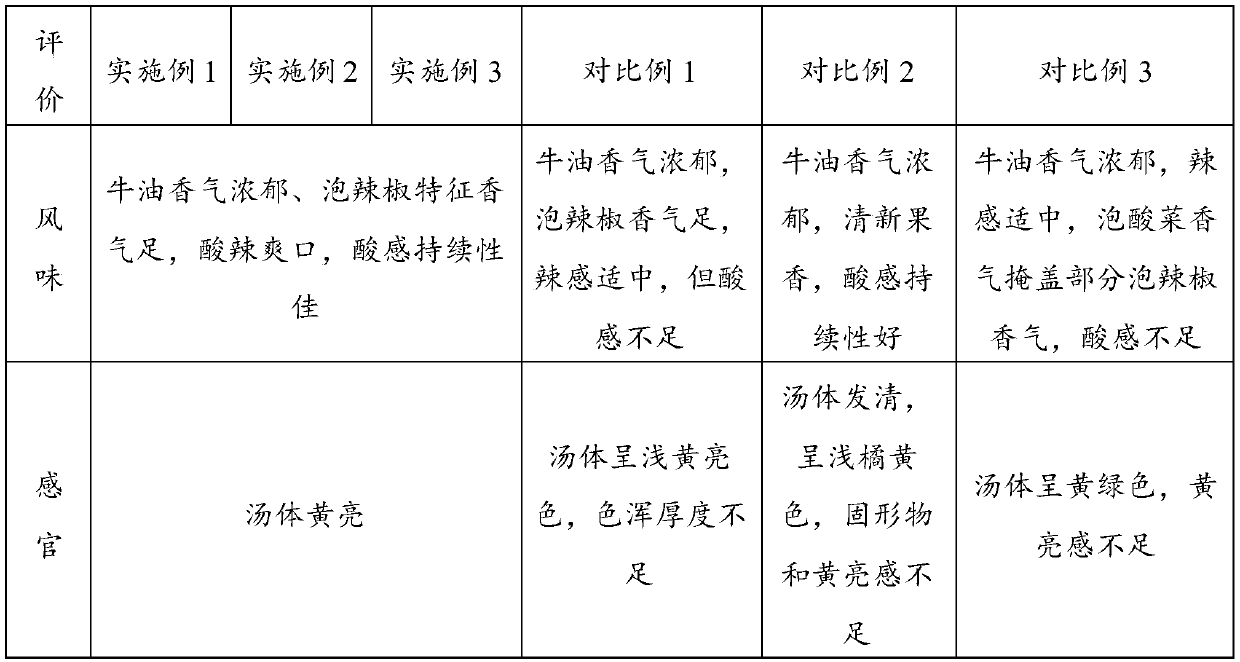

[0032] The preparation raw material of hot and sour butter hot pot base material provided by the present invention adopts salted yellow pepper, which not only has unique fermented sour taste and fermentation aroma, but also has obvious recognition in taste and smell, but the sour taste of salted pepper is in The hot pot base is not enough, and the sourness is not prominent when eating. In this production method, seabuckthorn fruit raw materials are added at the same time, which synergistically enhances the sourness of the product, coordinates the acidity and spiciness of the product, and gives the product a sour taste. At the same time, the acidity of seabuckthorn changes slowly after being heated, which can delay the decline in acidity during the hot and sour hot pot bottom material. speed.

[0033] In some specific embodiments of the present invention, the mass ratio of described salted yellow pepper and seabuckthorn is 32.5:3;

[0034] In some specific implementations of t...

Embodiment 1

[0066] A method of making salted yellow pepper sauce hot and sour butter hot pot base:

[0067] (1) Raw material pretreatment: total acid is 1.1g / 100g, 32.5kg of salted yellow pepper is crushed into 5-6mm particles, 6kg of garlic is crushed into 5-6mm particles, 5kg of salted ginger is crushed into 4-5mm particles, 0.7kg of Chinese prickly ash, 0.8kg of white pepper, and 0.5kg of cumin are crushed into 3mm particles;

[0068] (2) Steaming: Heat 53kg of butter to 115°C, add 6kg of fresh garlic and fry for 8 minutes until the surface turns yellow, add spice powder, and fry for 1 minute;

[0069] (3) Make hot and sour butter hot pot bottom material: Add 5kg salted ginger, 32.5kg salted yellow pepper and stir-fry for 10 minutes until the water vapor is dry; add 5kg of edible salt, 7kg of monosodium glutamate, 8kg of white sugar, beef Mix 5kg powder, 1.2kg citric acid, and 3kg seabuckthorn evenly; fill, and cool for 35 minutes at 2°C to shape.

Embodiment 2

[0071] A method of making salted yellow pepper sauce hot and sour butter hot pot base:

[0072] (1) Raw material pretreatment: total acid is 1.1g / 100g, 30kg of salted yellow pepper is crushed into 5-6mm particles, 4kg of garlic is crushed into 5-6mm particles, 4kg of salted ginger is crushed into 4-5mm particles, Chinese prickly ash is crushed into 5-6mm particles, 0.5kg, white pepper 0.7kg, cumin 0.4kg crushed into 3mm particles;

[0073] (2) Steaming: Heat 51kg of butter to 110°C, add 4kg of fresh garlic and fry for 5 minutes until the surface turns yellow, add spice powder, and fry for 1 minute;

[0074] (3) Make hot and sour butter hot pot bottom material: Add 4kg salted ginger, 30kg salted yellow pepper and fry for 8 minutes until the water vapor is dry; add 4kg of edible salt, 6kg of monosodium glutamate, 7kg of white sugar, beef powder 4kg, 1.1kg citric acid, and 2kg seabuckthorn are stirred evenly; filled, and cooled for 30 minutes at 0°C to shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com