Dust treatment system for calcium carbonate production

A technology of dust treatment and calcium carbonate, applied in the direction of using liquid separation agent, chemical/physical process, mixer, etc., can solve the problems of inability to handle calcium carbonate powder, affecting water source and soil quality, etc., to avoid affecting water source and soil quality, saving energy The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

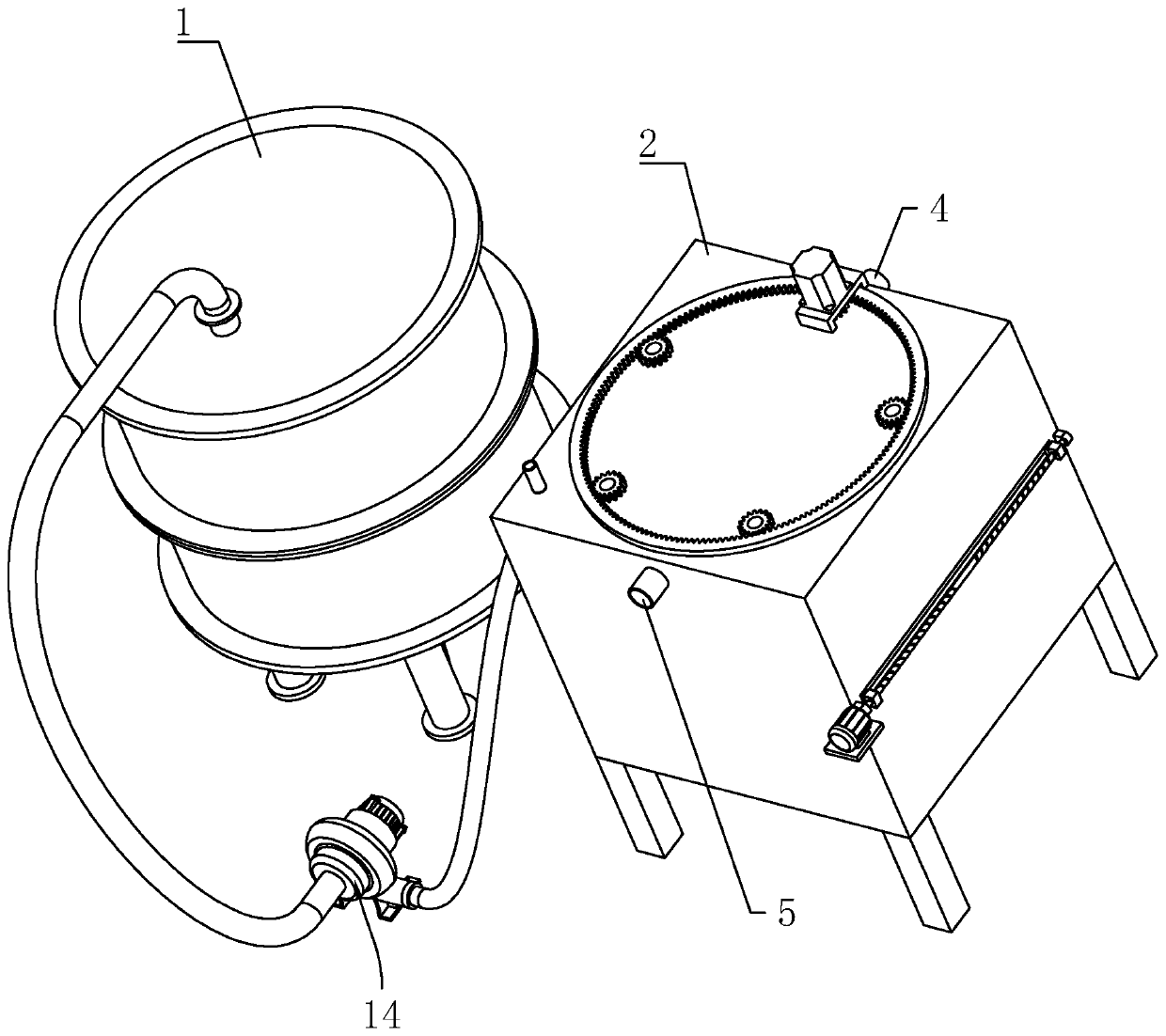

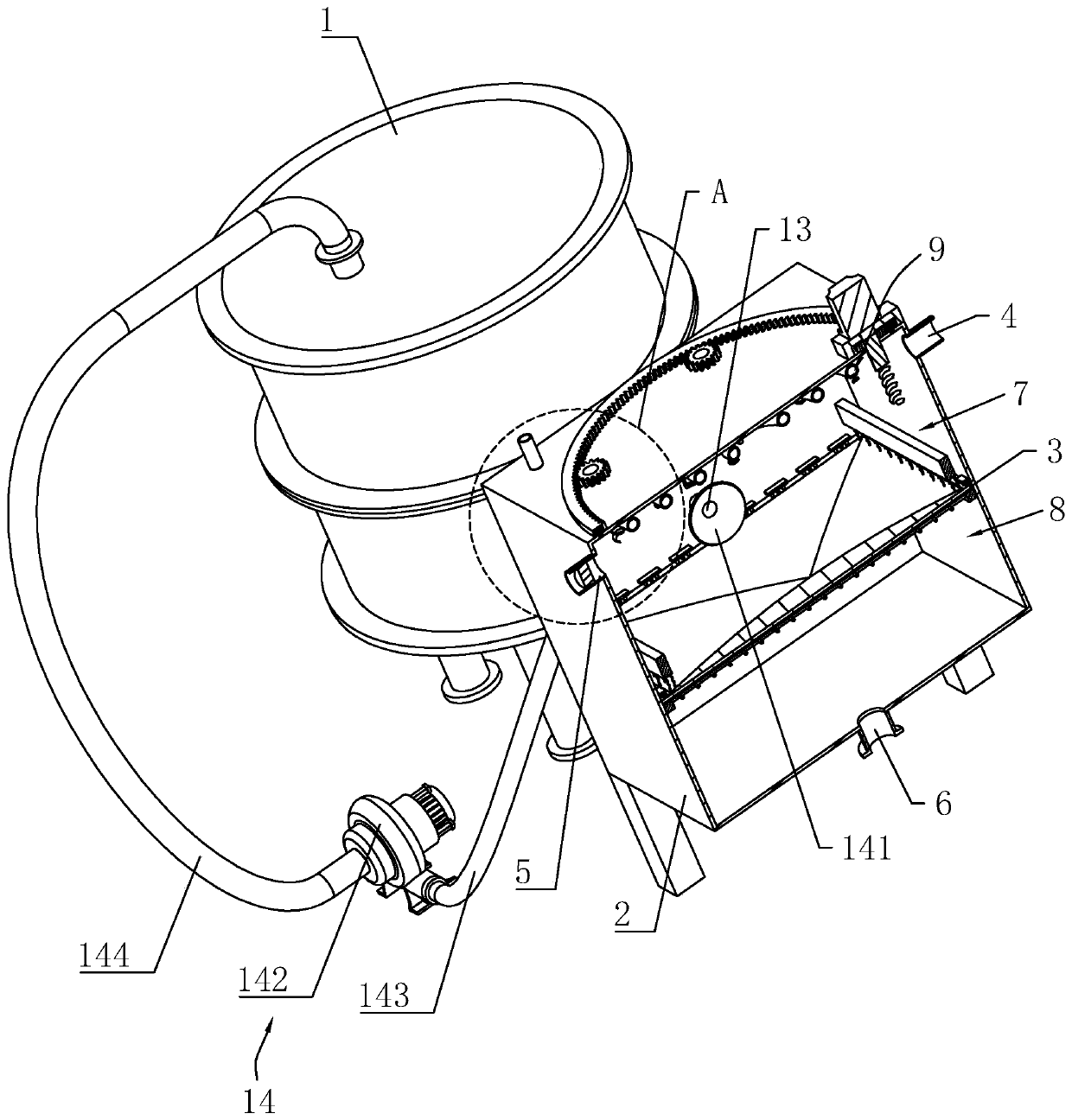

[0044] refer to figure 1 , a dust treatment system for calcium carbonate production, comprising a dust collection box 2 and a disc dryer 1, the upper end sidewall of the dust collection box 2 is respectively provided with a dust inlet pipe 4 and an exhaust pipe 5, during actual processing, the The dust pipe 4 is connected with an air pump (not shown in the figure), and the dust generated during calcium carbonate production can be sucked into the dust collection box 2 inside.

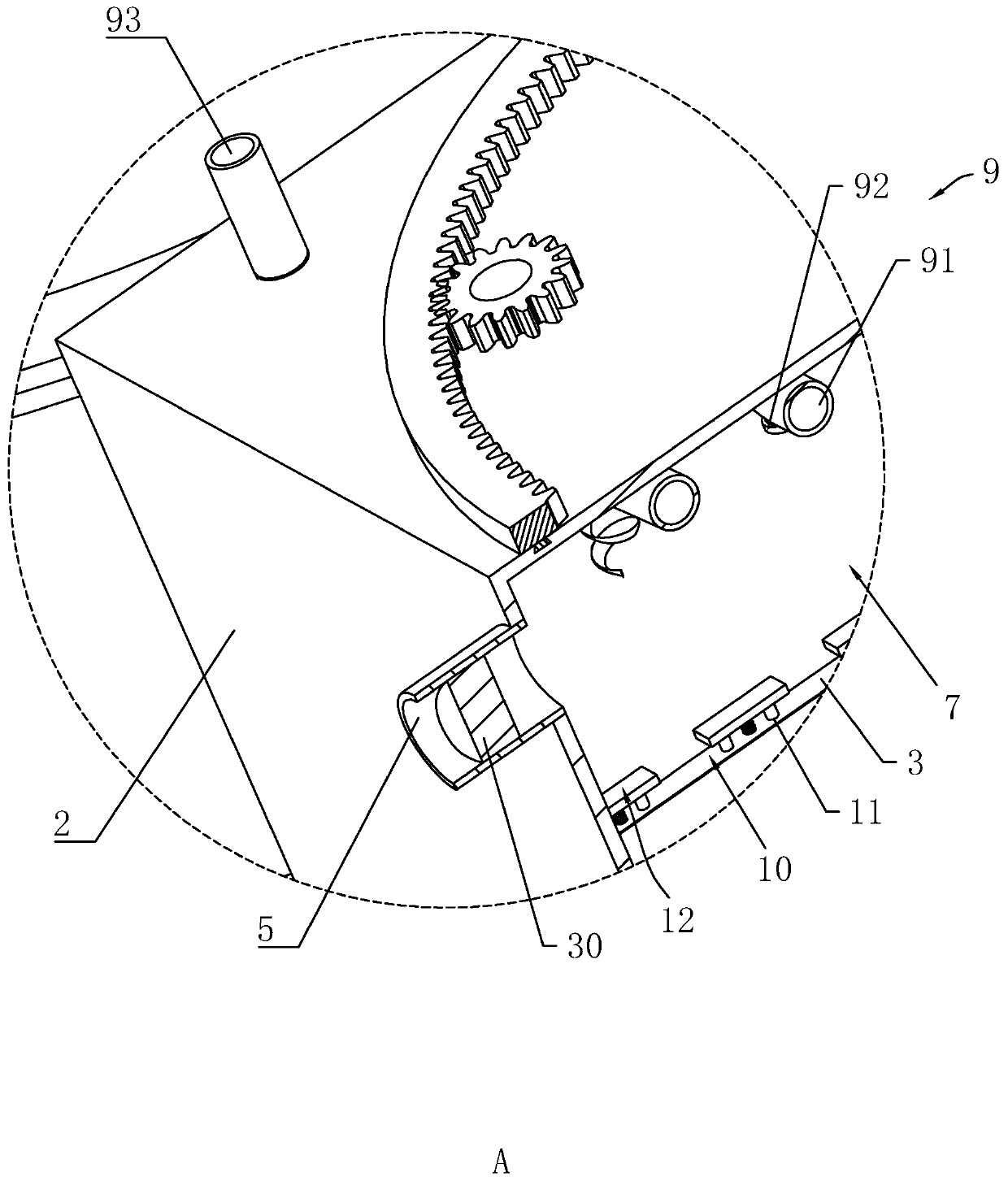

[0045] refer to figure 1 with figure 2 , the inner top wall of the dust collection box 2 is provided with an atomized dust suppression part 9, and the middle part of the inner wall of the dust collection box 2 is equipped with a dust filter plate 3, and the upper and lower surfaces of the dust filter plate 3 are respectively connected with the inner top wall and the inner bottom wall of the dust collection box 2. A dust-suppression chamber 7 and a drainage chamber 8 are enclosed between them, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com