A heavy-duty fast press

A press and heavy-duty technology, applied to pressure vessels used in chemical processes, etc., can solve problems such as poor safety, limited development, and serious equipment loss, and achieve structural optimization, increase gas temperature and pressure, and compact structural layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

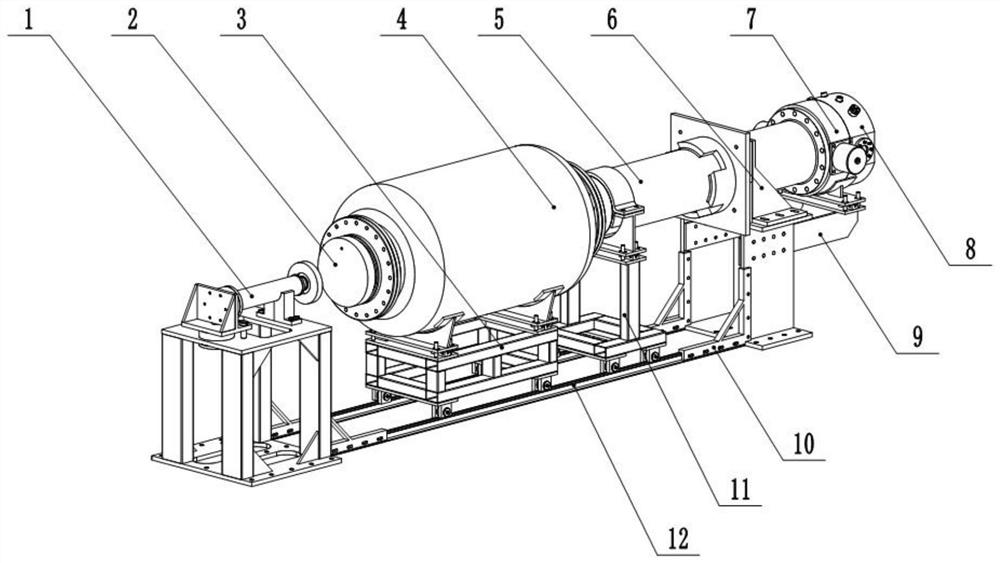

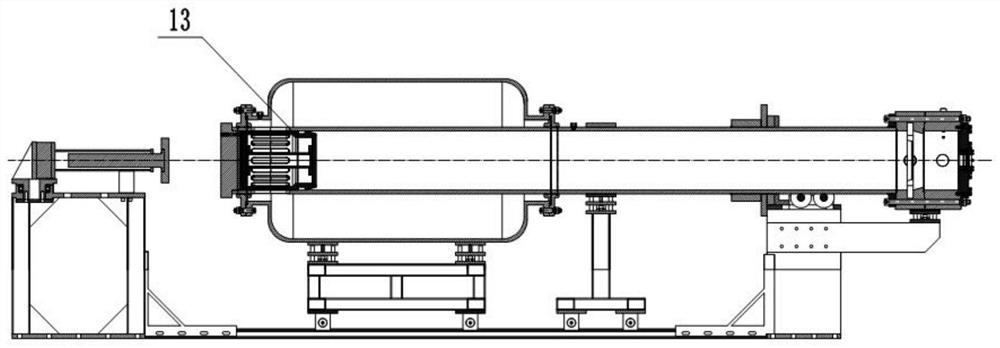

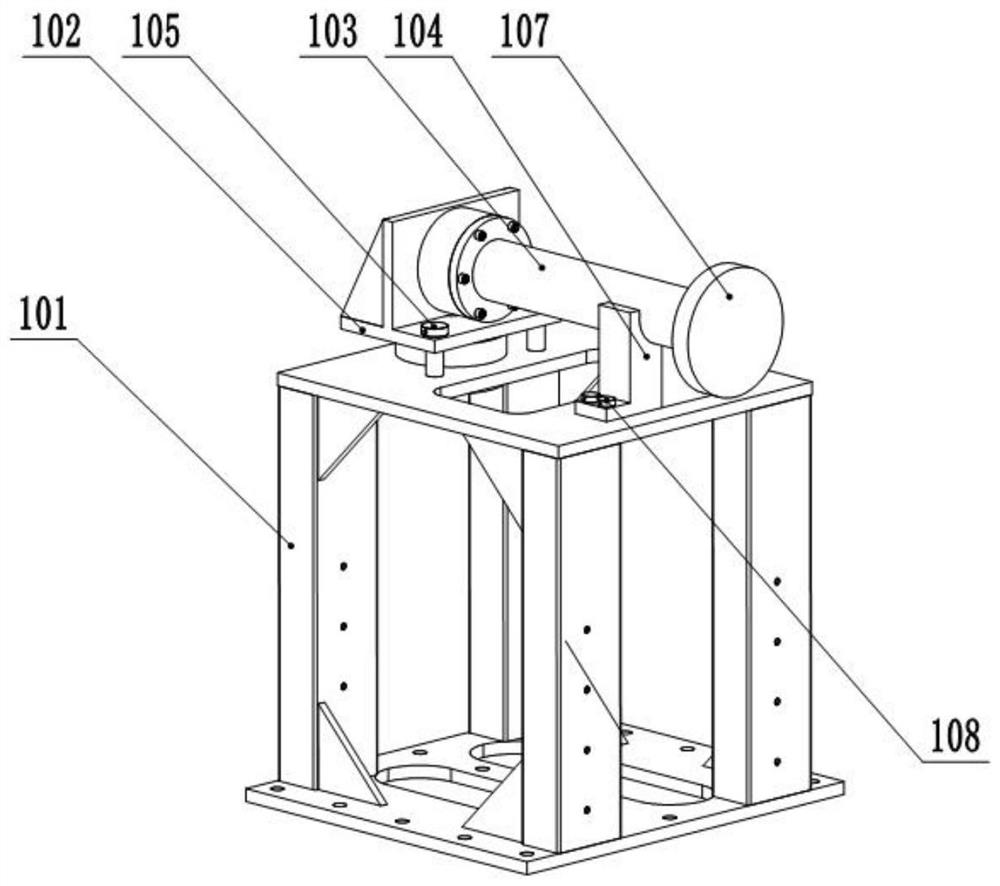

[0052] like Figure 1-13As shown, a heavy-duty quick press includes a hydraulic push assembly 1, a nylon plug 2, a high-pressure tank support assembly 3, a high-pressure tank 4, a compression tube 5, a compression tube thrust assembly 6, a heavy piston backstop assembly 7, an experimental cabin Assembly 8, experimental cabin support assembly 9, triangular fixing frame 10, compression pipe support assembly 11, steel rail 12, and heavy piston 13, the nylon plug 2, high pressure tank 4, compression pipe 5, heavy piston stop assembly 7 and experiment The cabin assemblies 8 are arranged and connected in sequence to form a closed experimental device. The hydraulic push assembly 1 is located on the left side of the high pressure tank 4, the compression pipe 5 penetrates into the central hole of the high pressure tank 4, the nylon plug 2 is installed on the left end face of the compression pipe 5, the high pressure The tank 4 is supported by the high-pressure tank support assembly 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com