Nonstop refrigeration house plate cutting machine capable of improving cutting efficiency

A technology for cutting efficiency and cold storage boards, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems affecting the quality of cold storage boards, the cutting surface is not complete, and the cutting efficiency is affected, so as to achieve accurate cutting and slow down the extrusion force , the effect of improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

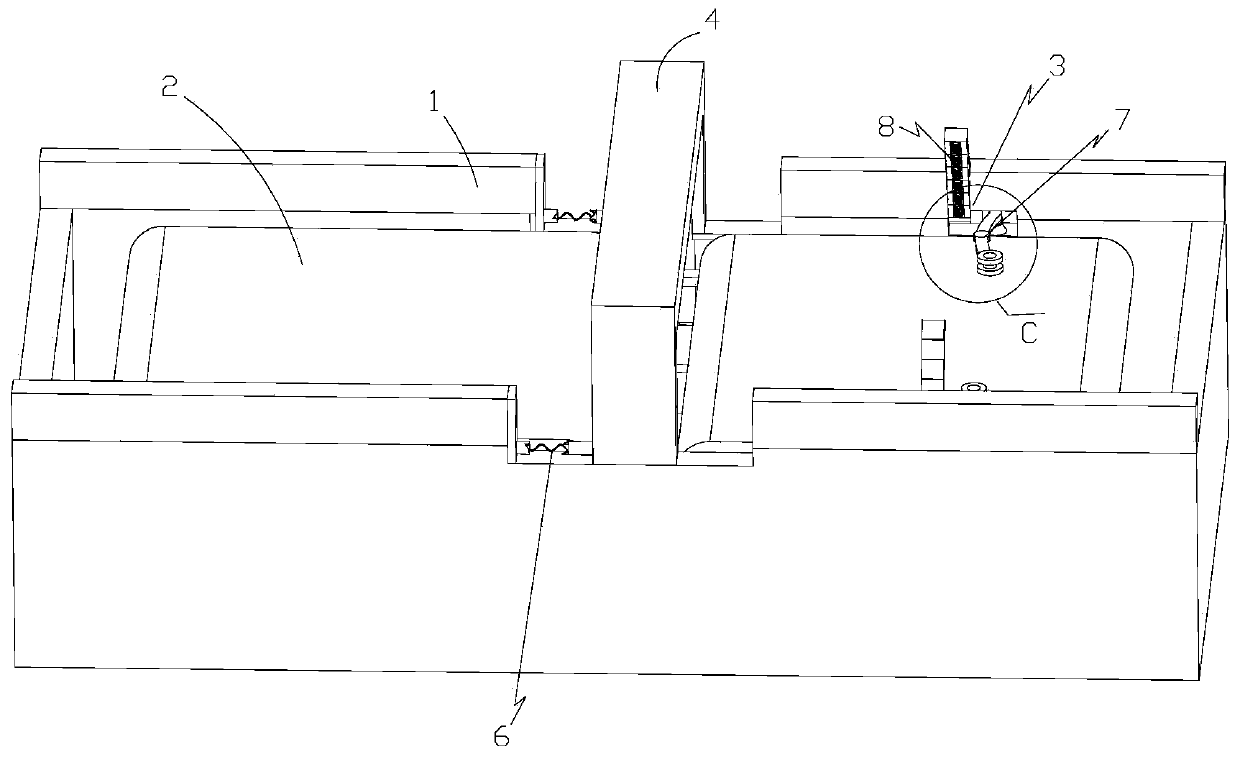

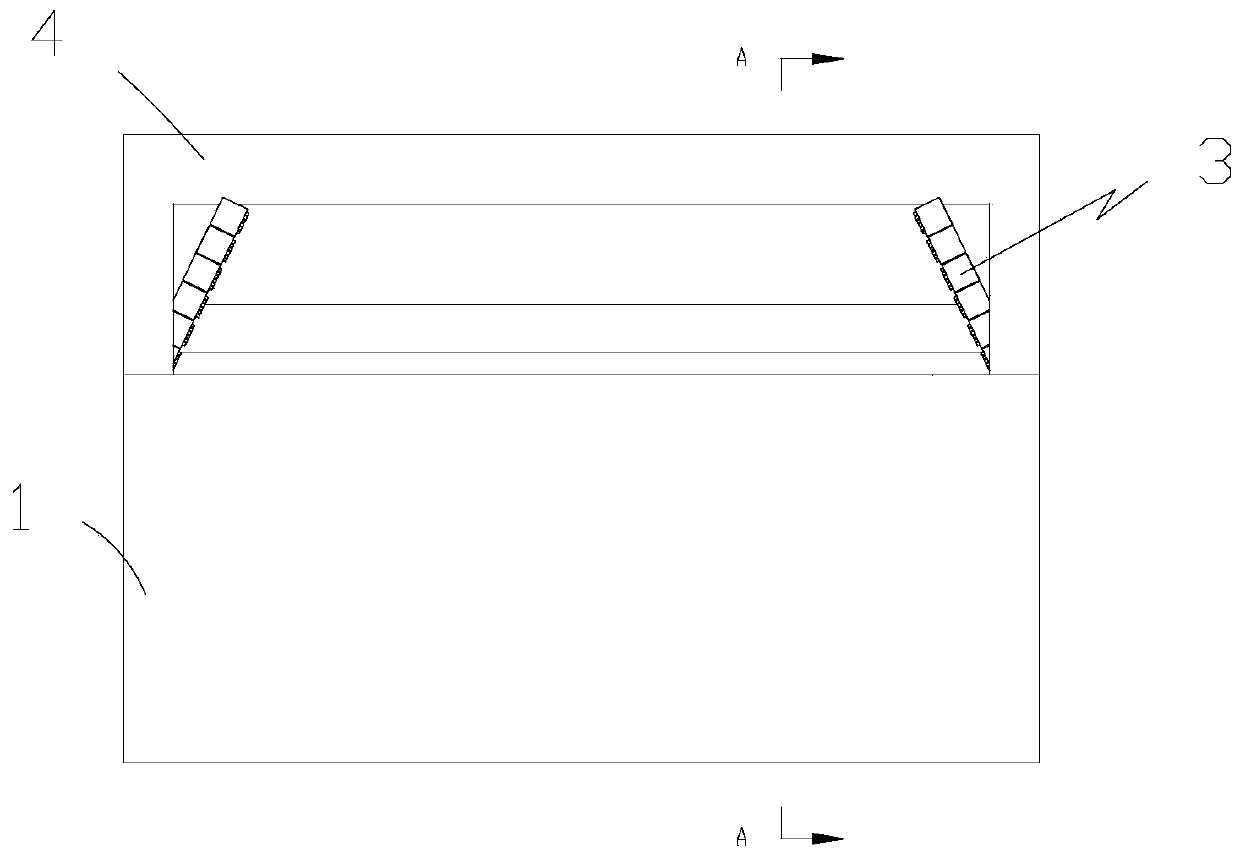

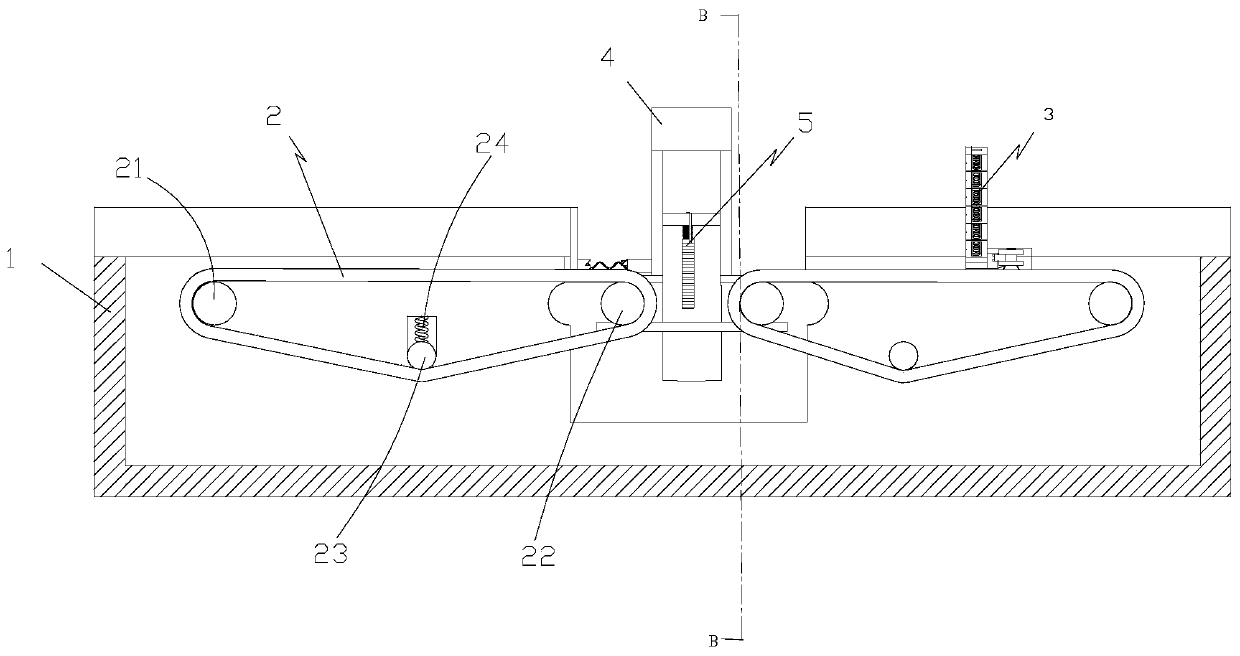

[0030] Such as Figure 1-11 As shown, a non-stop cold storage panel cutting machine that can improve cutting efficiency includes a housing 1, a conveyor belt 2, a positioning device 3, a moving frame 4, a cutting device 5 and a buffer device 6; the positioning device 3 includes a first helical gear 31. The first torsion spring 32, the adjustment mechanism 7, the second helical gear 33, and the pressure plate mechanism 8; the conveyor belts 2 are two groups, which are arranged on the housing 1, and the distance between the two groups of conveyor belts is 100mm; The positioning device 3 is located on the conveyor belt 2 and is located on the right side; the axis of the first helical gear 31 is perpendicular to the bottom surface of the housing 1 and is located on the inner wall of the housing 1; the first torsion spring 32 One end is set on the first helical gear 31, and the other end is fixed on the side wall of the housing 1; the adjustment mechanism 7 is set on the first heli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com