Transit type vacuum excrement collecting system for train, and control method

A vacuum collection and train technology, applied in railway car body parts, sanitary equipment, transportation and packaging, etc., can solve problems such as troublesome use of passengers, influence on system working stability and reliability, and unavailability of toilets or sinks. The effect of improving work stability, improving work stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

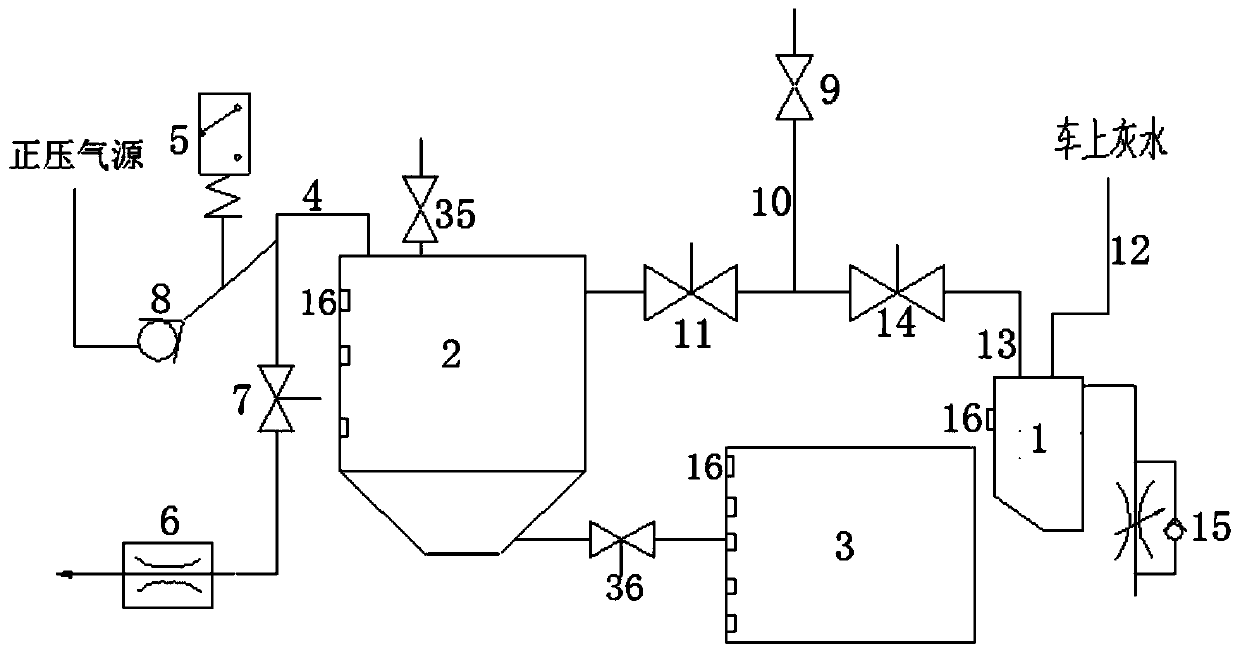

[0049] Such as figure 1 As shown, a kind of transit-type vacuum stool collection system for trains provided by the present invention comprises a dirt box composition, a toilet composition, gray water discharge equipment, an electrical control unit, a pneumatic control unit, a water booster unit, and a flushing button (in the figure not shown), etc.

[0050] Wherein, the dirt tank consists of a gray water tank 1, a transfer tank 2 and a dirt tank 3. Gray water discharge equipment includes sinks, floor drains, etc. The toilet composition is the interface of the system to the user, including a toilet or a squatting toilet, etc., and is used to transfer passenger excrement flushing to the transfer box 2 for storage. The gray water discharged from the sink, floor drain, etc. is temporarily stored in the gray water tank 1, and then transferred to the transfer tank 2 when the tank is full. The transfer box 2 is used to collect and temporarily store the sewage discharged from the t...

Embodiment 2

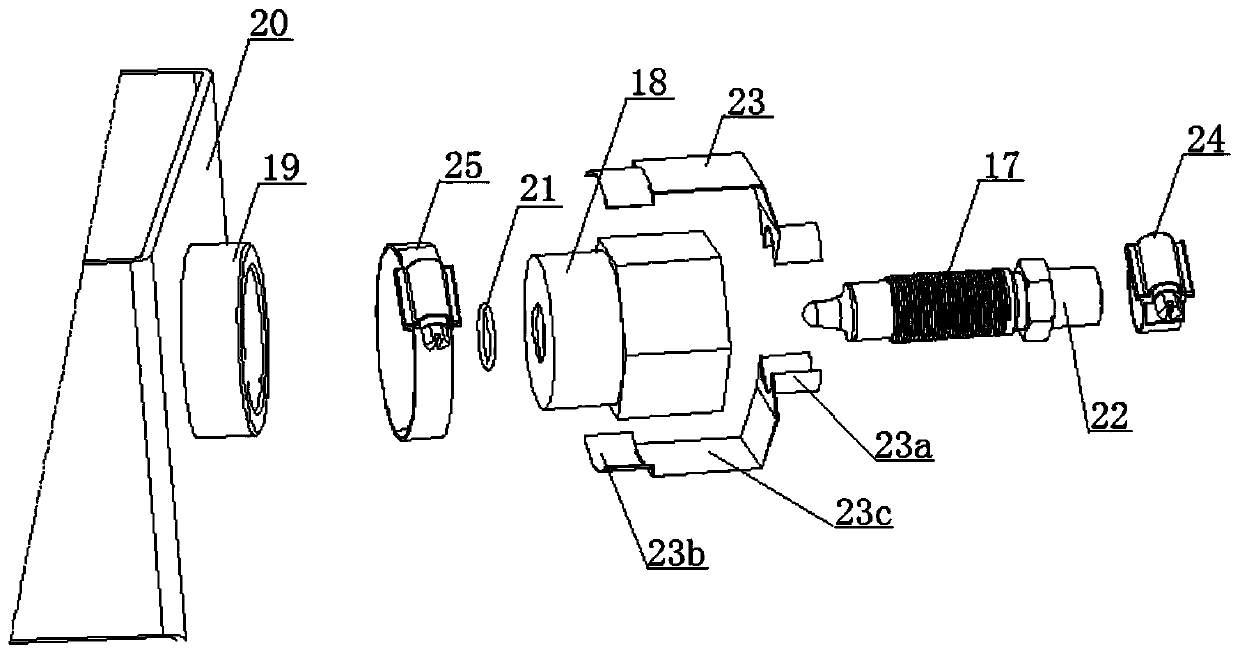

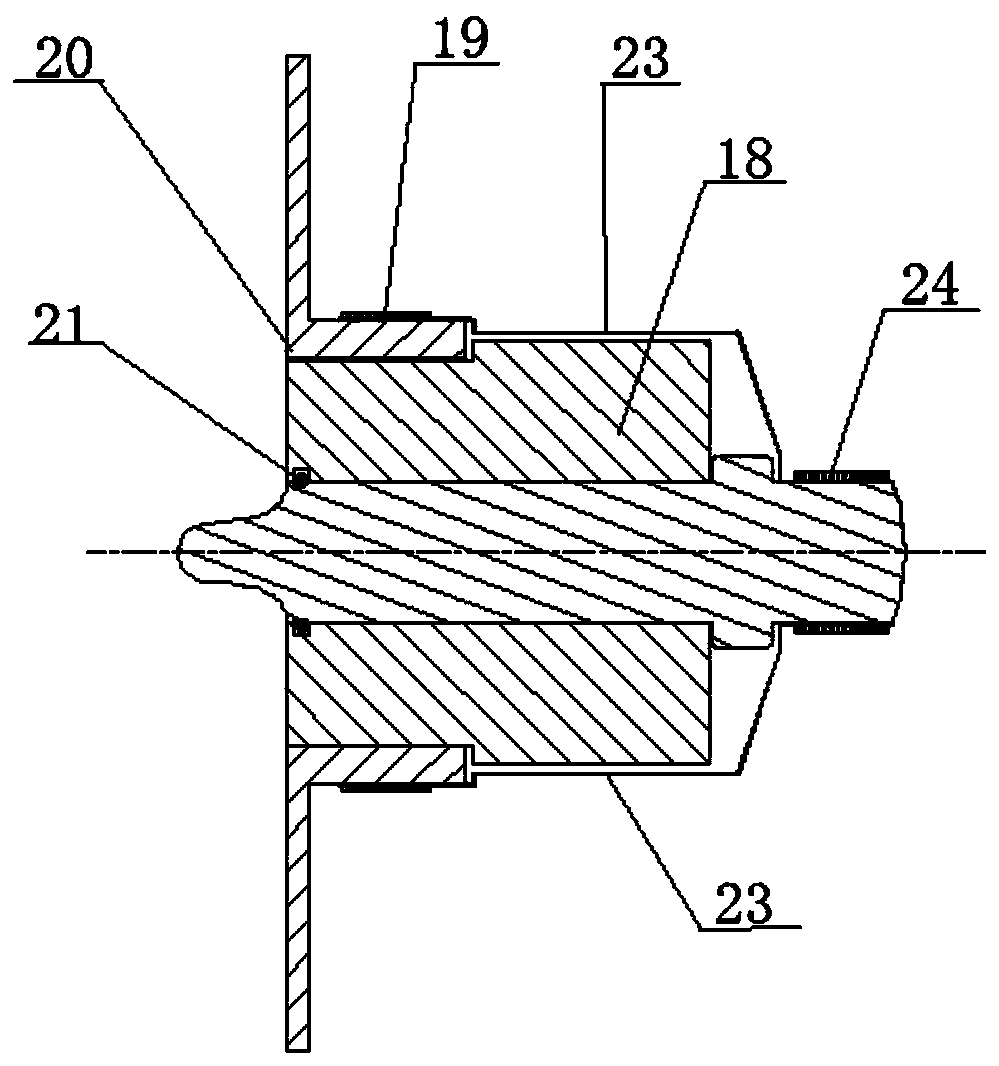

[0077] Such as Figure 7 and Figure 8 As shown, the first fixing part 23a of the grounding piece 23 adopts the same outwardly protruding arc structure as the first embodiment, and is fitted outside the metal shell 22 during installation. The circular surface contact is used for complete fit, and the fixed connection between the first fixing part 23 a and the metal shell 22 is realized by covering the first fastening throat clamp 24 .

[0078] The difference is that, in this embodiment, the second fixing part 23b adopts an insert structure with a U-shaped opening, which is inserted between the transition nut 18 and the metal mounting seat 19 during installation, so as to realize the connection between the second fixing part 23b and the metal mounting seat. 19 fixed connections.

Embodiment 3

[0080] The difference from the above-mentioned embodiments is that the first fixing part 23a of the grounding piece 23 adopts an insert structure with a U-shaped opening, and is inserted between the transition nut 18 and the metal shell 22 during installation, while the second fixing part 23b adopts a The outwardly protruding arc-shaped structure is set on the outside of the metal mounting seat 19 during installation, and the second fastening throat clamp 25 realizes a fixed connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com