Method for recycling and preparing modified polypropylene composite material from waste polypropylene pipeline

A composite material, polypropylene technology, applied in the field of polymer material processing, can solve problems such as uneven compatibility and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

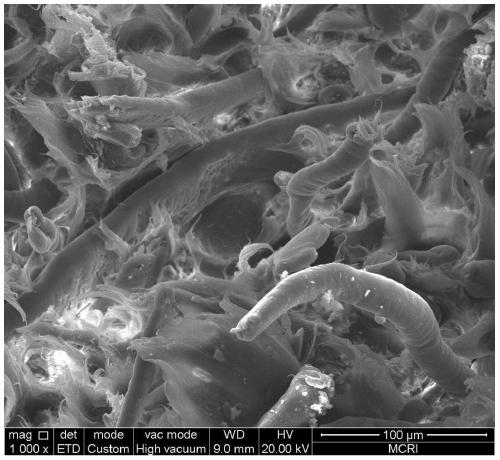

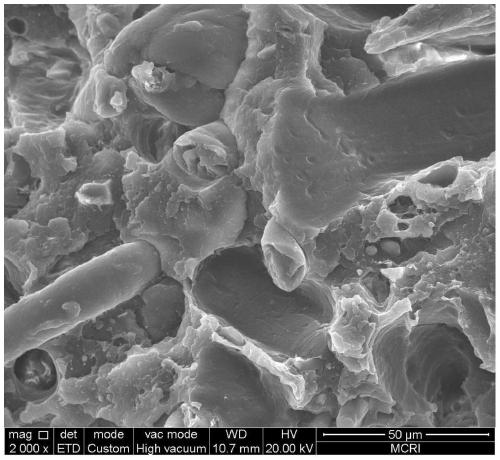

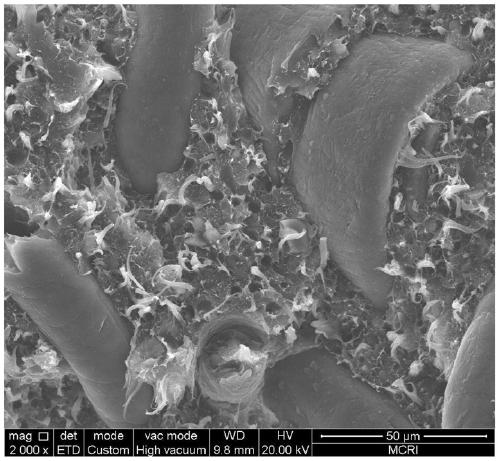

Image

Examples

Embodiment 1-22

[0031] (1) Remove dust, other plastics, iron materials and other impurities from the discarded polypropylene pipes with polyester, nylon, and spandex attached to the surface, crush them, and dry them at 120°C for 6 hours to obtain recycled polypropylene pipes. The mass is 100Kg. Polyester, nylon, and spandex attached to the surface have a relatively light specific gravity, which is about 0.5-5% of the total mass of recycled polypropylene pipes, and their weight can almost be ignored. Therefore, the quality of attached polyester, nylon, and spandex is included in the recycled polypropylene pipe. in.

[0032] (2) Prepare materials according to the ingredients and mass percentages shown in Table 1 and Table 2. First, dry the prepared polyester, nylon, and spandex and mix them uniformly to obtain a mixture of polyester, nylon and spandex.

[0033] (3) Mix the prepared recycled polypropylene pipeline with the above-mentioned mixture again, and perform hot-pressing treatment through a p...

Embodiment 23-27

[0046] (1) Remove dust, other plastics, iron materials and other impurities from the discarded polypropylene pipes with polyester, nylon, and spandex attached to the surface, crush them, and dry them at 120°C for 6 hours to obtain recycled polypropylene pipes. The mass is 100Kg. Polyester, nylon, and spandex attached to the surface have a relatively light specific gravity, which is about 0.5-5% of the total mass of recycled polypropylene pipes, and their weight can almost be ignored. Therefore, the quality of attached polyester, nylon, and spandex is included in the recycled polypropylene pipe. in.

[0047] (2) Prepare materials according to the ingredients and mass percentages shown in Table 5. First, the prepared polyester, nylon, and spandex are dried and mixed uniformly to obtain a mixture of polyester, nylon, and spandex.

[0048] (3) Mix the prepared recycled polypropylene pipeline with the above-mentioned mixture again, pass the banbury mixing, the banbury temperature is 22...

Embodiment 28-32

[0056] (1) Remove dust, other plastics, iron materials and other impurities from the discarded polypropylene pipes with polyester, nylon, and spandex attached to the surface, crush them, and dry them at 120°C for 6 hours to obtain recycled polypropylene pipes. The mass is 100Kg. Polyester, nylon, and spandex attached to the surface have a relatively light specific gravity, about 0.5-5% of the total mass of the recycled polypropylene pipe, and their weight can almost be ignored. Therefore, the content of attached polyester, nylon, and spandex is included in the recycled polypropylene pipe. in.

[0057] (2) Prepare materials according to the ingredients and mass percentages shown in Table 7, where the mass ratio of polyester, nylon, and spandex in the mixture of polyester, nylon, and spandex is 1:1:1.

[0058] (3) Mix the prepared recycled polypropylene pipeline with the above-mentioned mixture, and process the pellets by a pellet machine at a pellet temperature of 150°C and pellet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com