Traffic road intersection flow monitoring system

A flow monitoring and flow monitoring technology, applied in traffic control systems, traffic control systems of road vehicles, roads, etc., can solve the problem that signal lights cannot indicate road traffic operation, etc., to achieve convenient and fast maintenance process, convenient maintenance, and reduce traffic accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

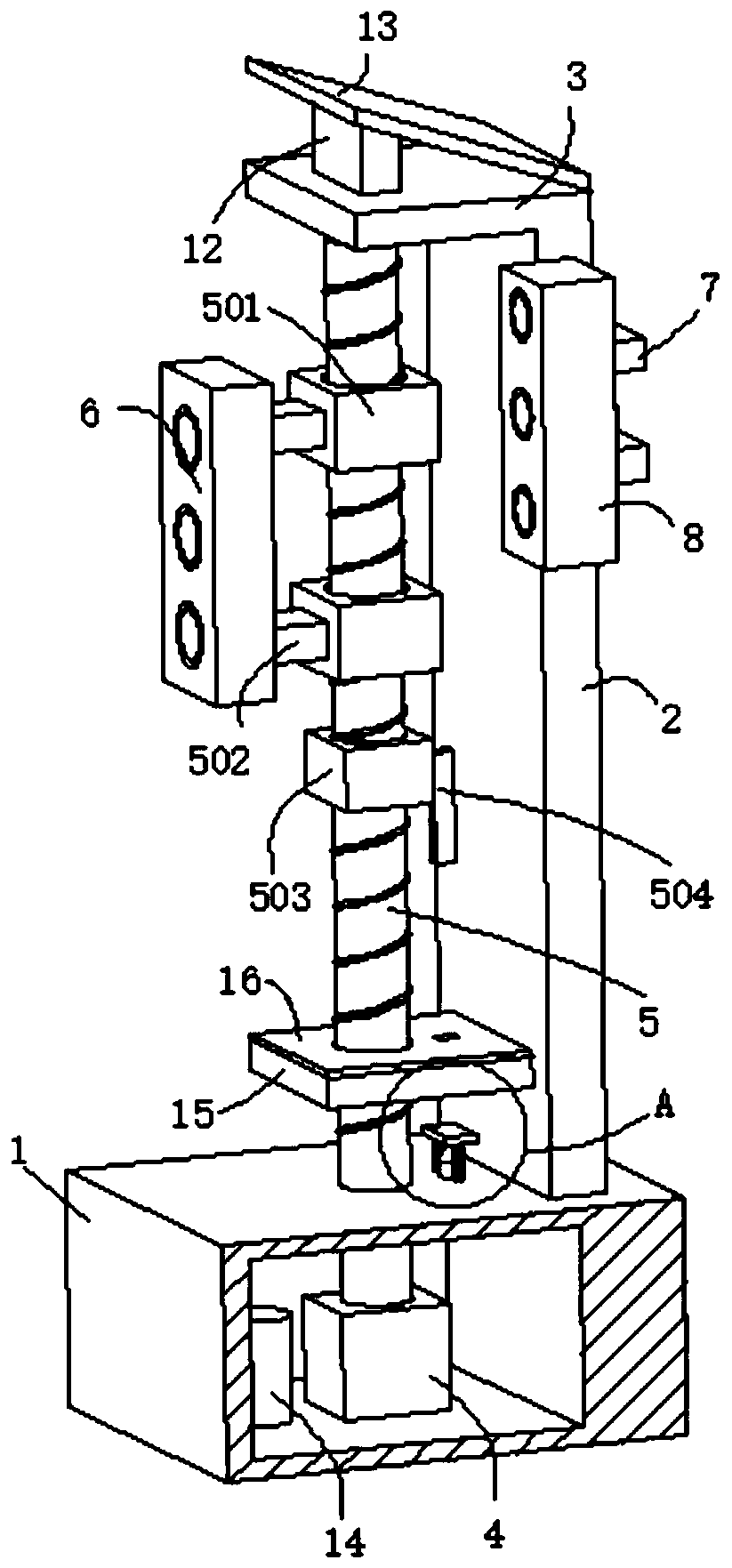

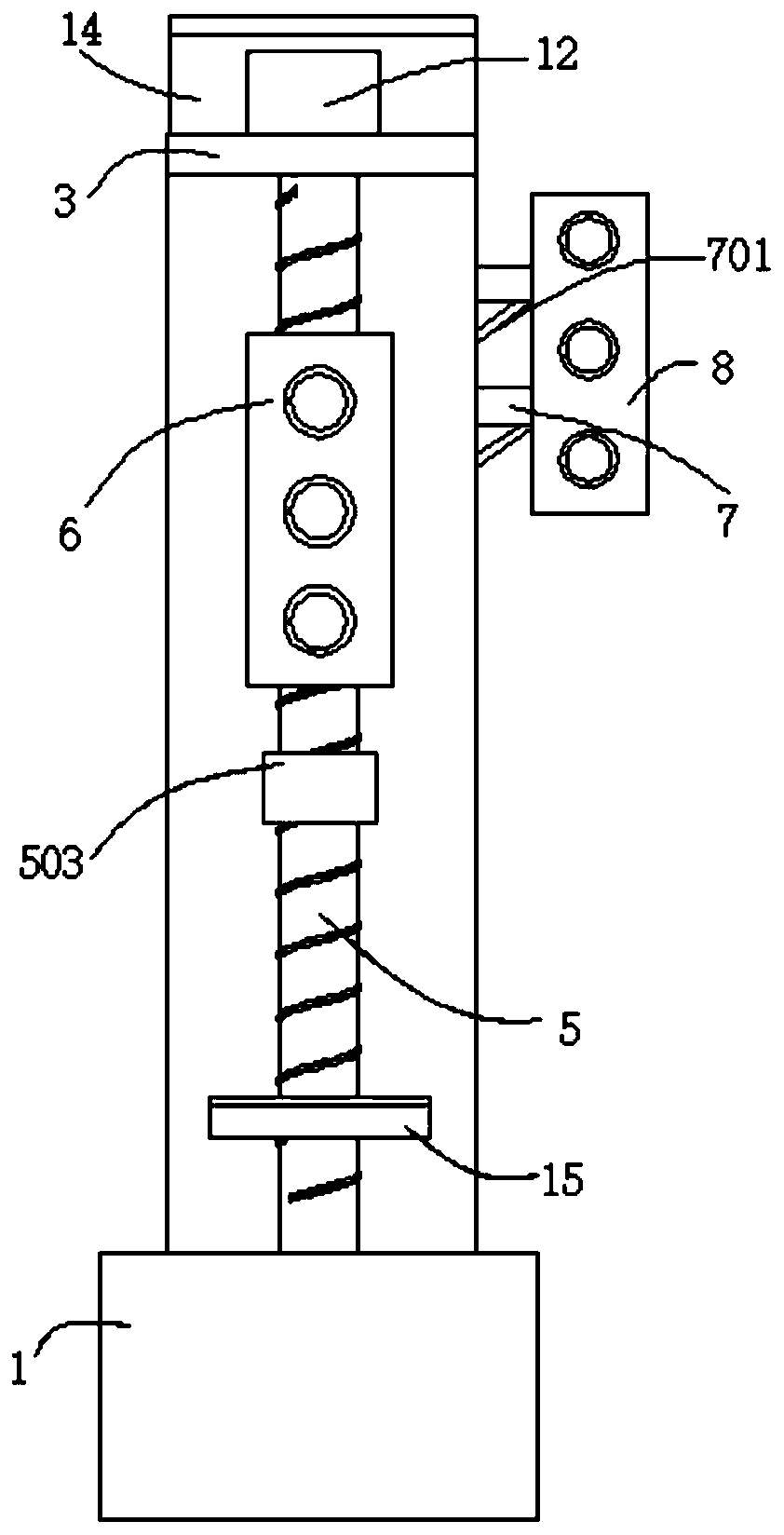

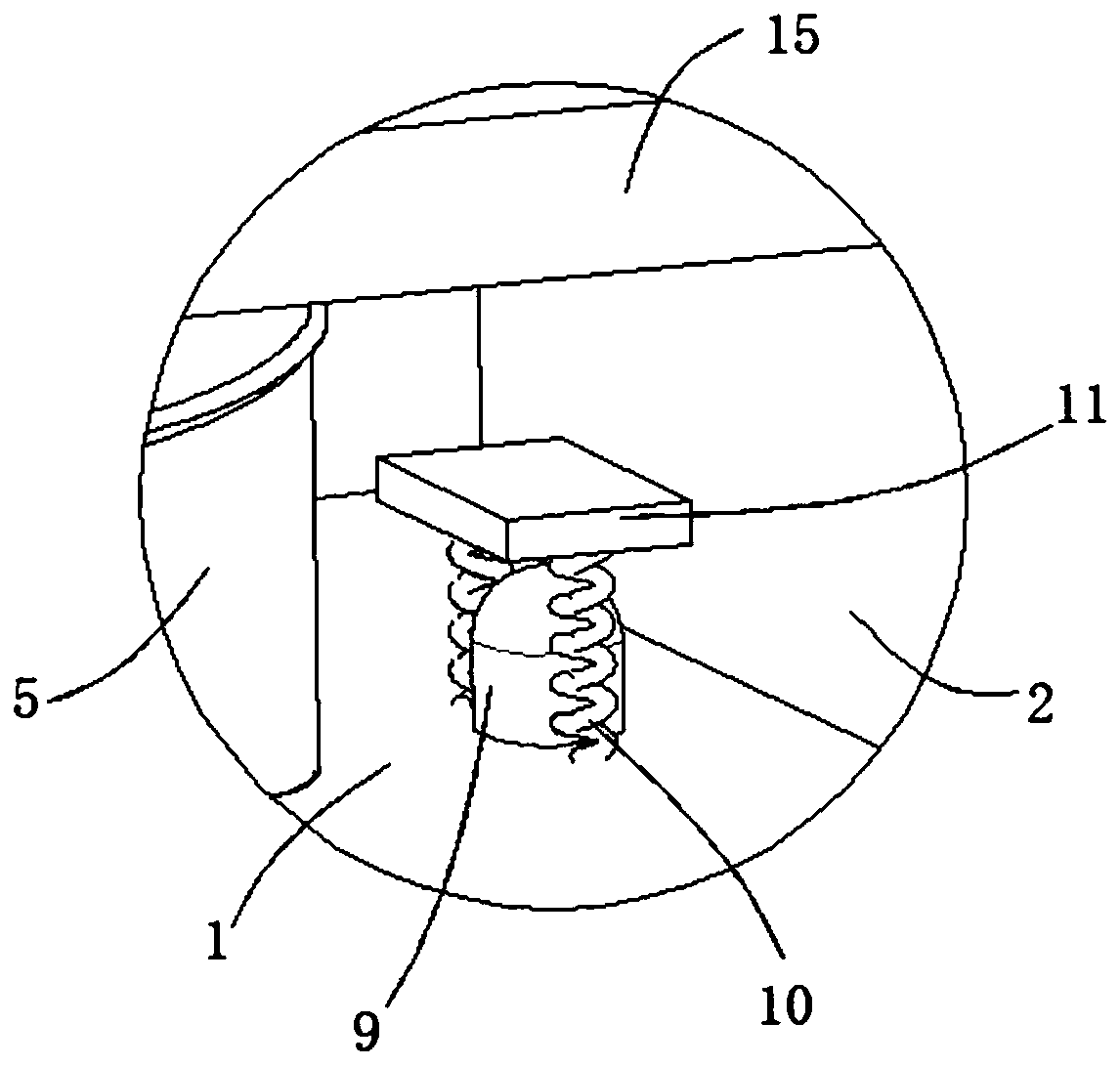

[0027] See Figure 1~3 , The present invention provides a traffic road junction flow monitoring system, including a base 1, a signal lamp system and a flow monitoring system. The top of the base 1 is connected with a vertical plate 2, and the end of the vertical plate 2 away from the base 1 is connected with a top plate 3. The base 1 The inner wall is connected with a motor 4, and the output end of the motor 4 is connected with a rotating shaft. The end of the rotating shaft away from the motor 4 passes through the base 1 and is connected with a screw rod 5. The top of the screw rod 5 is connected to the bottom wall of the top plate 3 through a bearing. 5 The outer wall is threadedly connected with a first sleeve 501, the outer wall of the first sleeve 501 is connected with a connecting rod 502, the end of the connecting rod 502 away from the first sleeve 501 is connected with a first signal lamp 6, and the outer wall of the vertical plate 2 is connected with a supporting rod 7 ...

Embodiment 2

[0030] See Figure 1~4 , The present invention provides a traffic road junction flow monitoring system, including a base 1, a signal lamp system and a flow monitoring system. The top of the base 1 is connected with a vertical plate 2, and the end of the vertical plate 2 away from the base 1 is connected with a top plate 3. The base 1 The inner wall is connected with a motor 4, and the output end of the motor 4 is connected with a rotating shaft. The end of the rotating shaft away from the motor 4 passes through the base 1 and is connected with a screw rod 5. The top of the screw rod 5 is connected to the bottom wall of the top plate 3 through a bearing. 5 The outer wall is threadedly connected with a first sleeve 501, the outer wall of the first sleeve 501 is connected with a connecting rod 502, the end of the connecting rod 502 away from the first sleeve 501 is connected with a first signal lamp 6, and the outer wall of the vertical plate 2 is connected with a supporting rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com