Control method of engine electronic water pump

A technology of electronic water pump and control method, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve the problems of inaccurate electronic water pump speed, hidden heat generation and heat dissipation overtemperature, failure to reach the combustion economy point, etc., to achieve Shorten warm-up time, improve heating comfort, and minimize fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

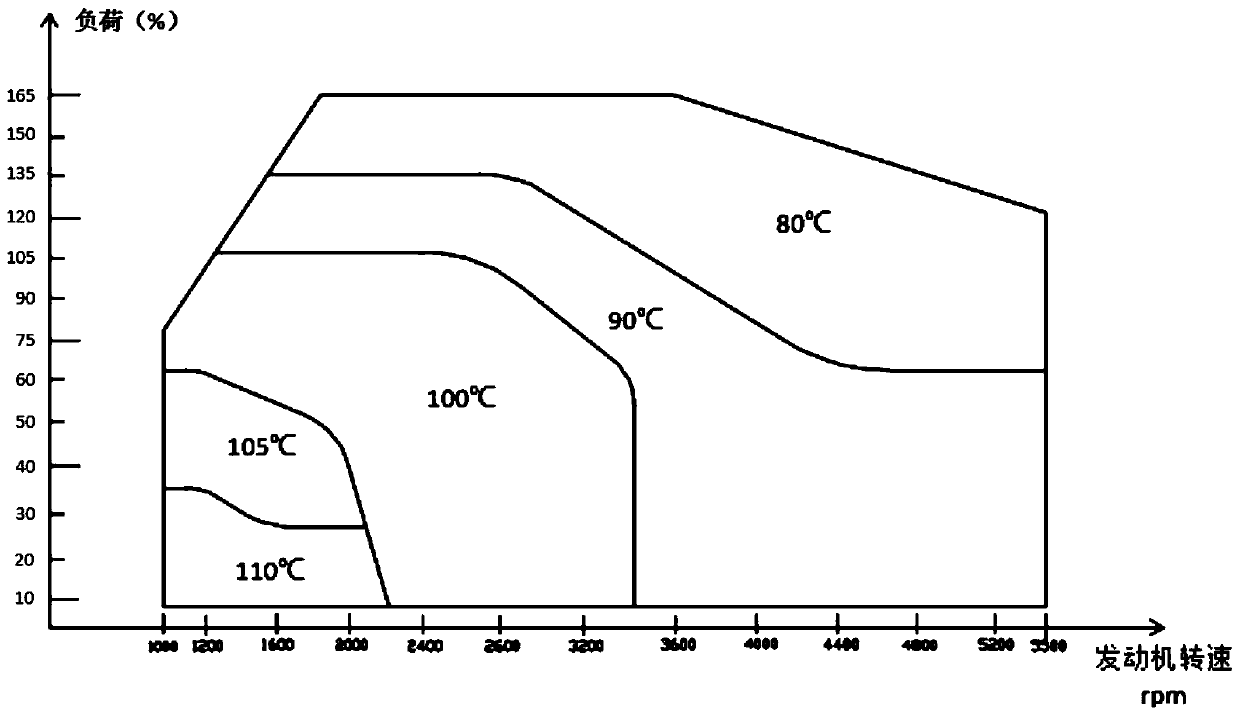

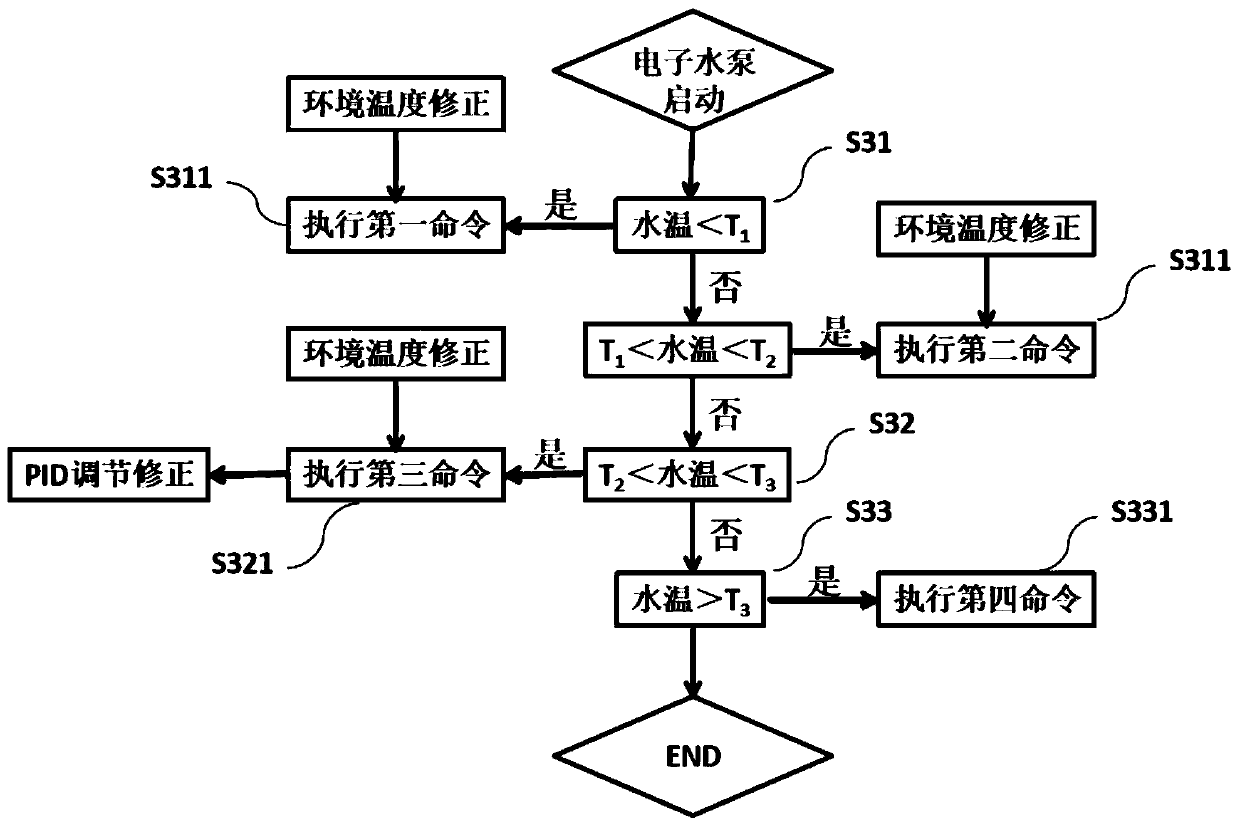

[0064] refer to Figure 1~2 , which is the first embodiment of the present invention. This embodiment provides a control method for the electronic water pump of the engine. The engine operating conditions are divided into multiple stages according to the engine coolant temperature, and the cooling system is implemented in each stage according to the It shortens the warm-up time, achieves the lowest power loss and fuel consumption rate, and realizes the needs of rapid heating and rapid cooling.

[0065] According to the temperature of the engine coolant, the operating conditions of the engine can be divided into five stages, namely, the warm-up stage, the heat-up stage, the water temperature protection stage, the response to air-conditioning demand stage, and the post-flame stage, including but not limited to the above five stages, and The cooling demand of the running state is included in the above situations as the basis for the division of the working state stage. In this em...

Embodiment 2

[0095] refer to image 3 , which is the second embodiment of the present invention. The difference from the previous embodiment is that this embodiment improves heating comfort and protects the engine from flameout by adding a stage of response to air conditioning demand and a stage after flameout for the engine operating conditions. After high temperature damage.

[0096] Specifically, following the steps in the previous embodiment, the method for controlling the electronic water pump of the engine further includes,

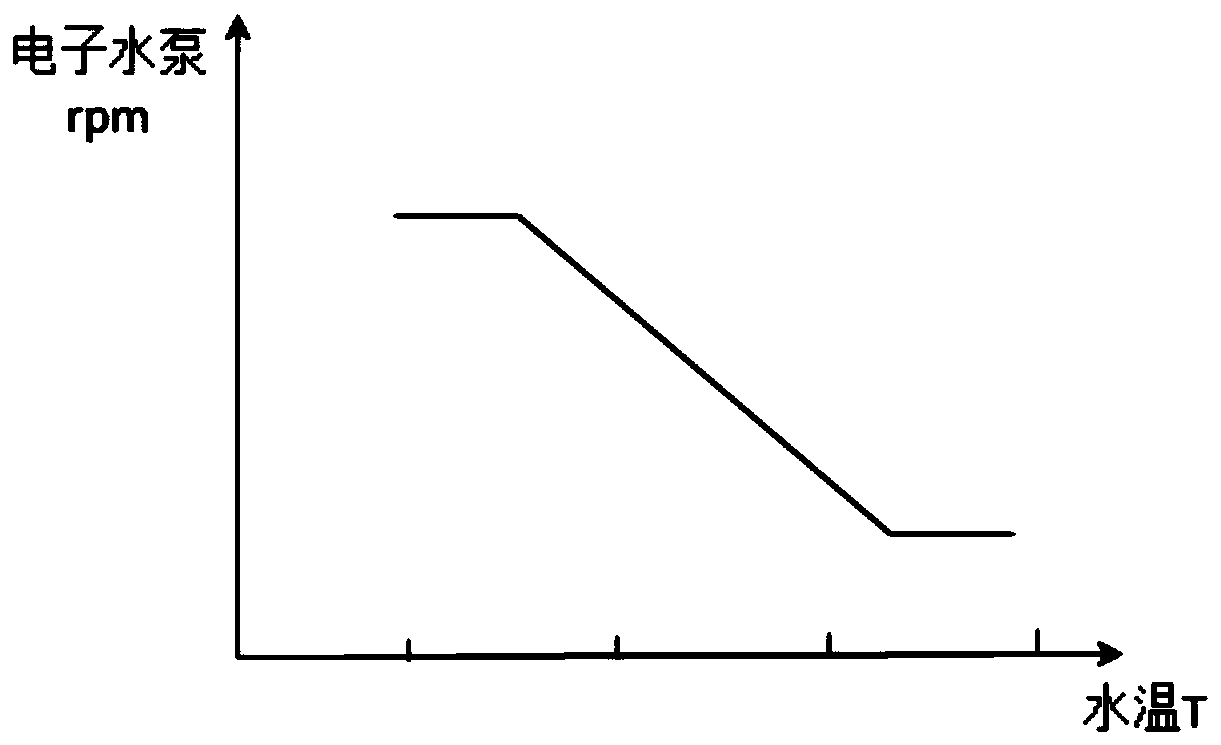

[0097] S4: When the working condition of the engine is in the stage of responding to the air conditioner demand, that is, when the damper opening percentage signal sent by AC to the ECU is greater than the warm air value, and the set wind level of the blower is greater than 0, respond to the fifth command MAP 5 : Based on the actual water temperature of the engine, control the electronic water pump at the sixth speed V 6 For long run, refer to image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com