Novel oscillating cylinder mechanism for hydraulic motor

A hydraulic motor, a new type of technology, applied in the field of hydraulic motors, can solve the problems that the position of the roller cannot be fixed all the time, the wear of the trunnion and the end cover, and the increase of the speed, so as to prevent the phenomenon of seizure, prolong the life of the parts, and improve the starting torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

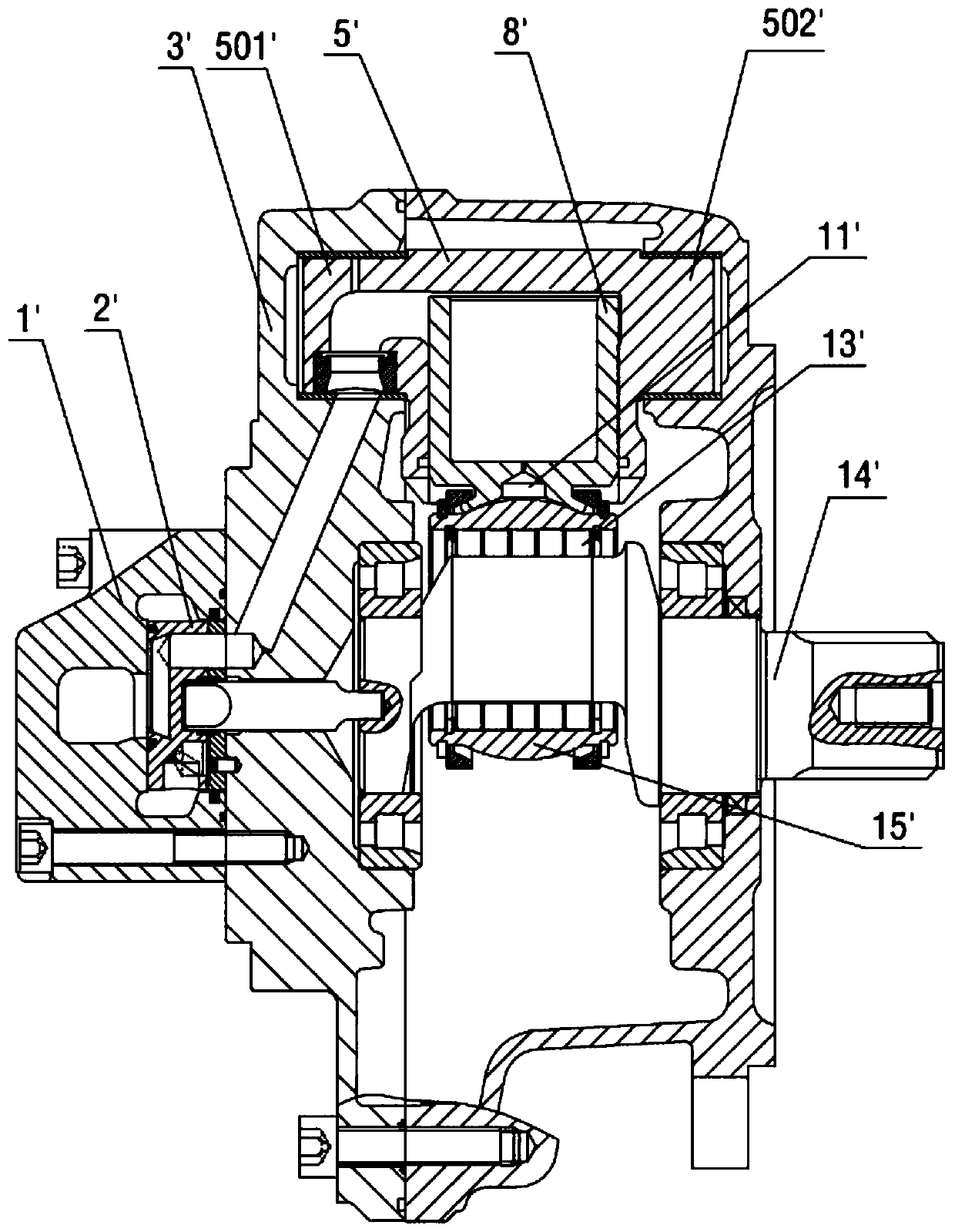

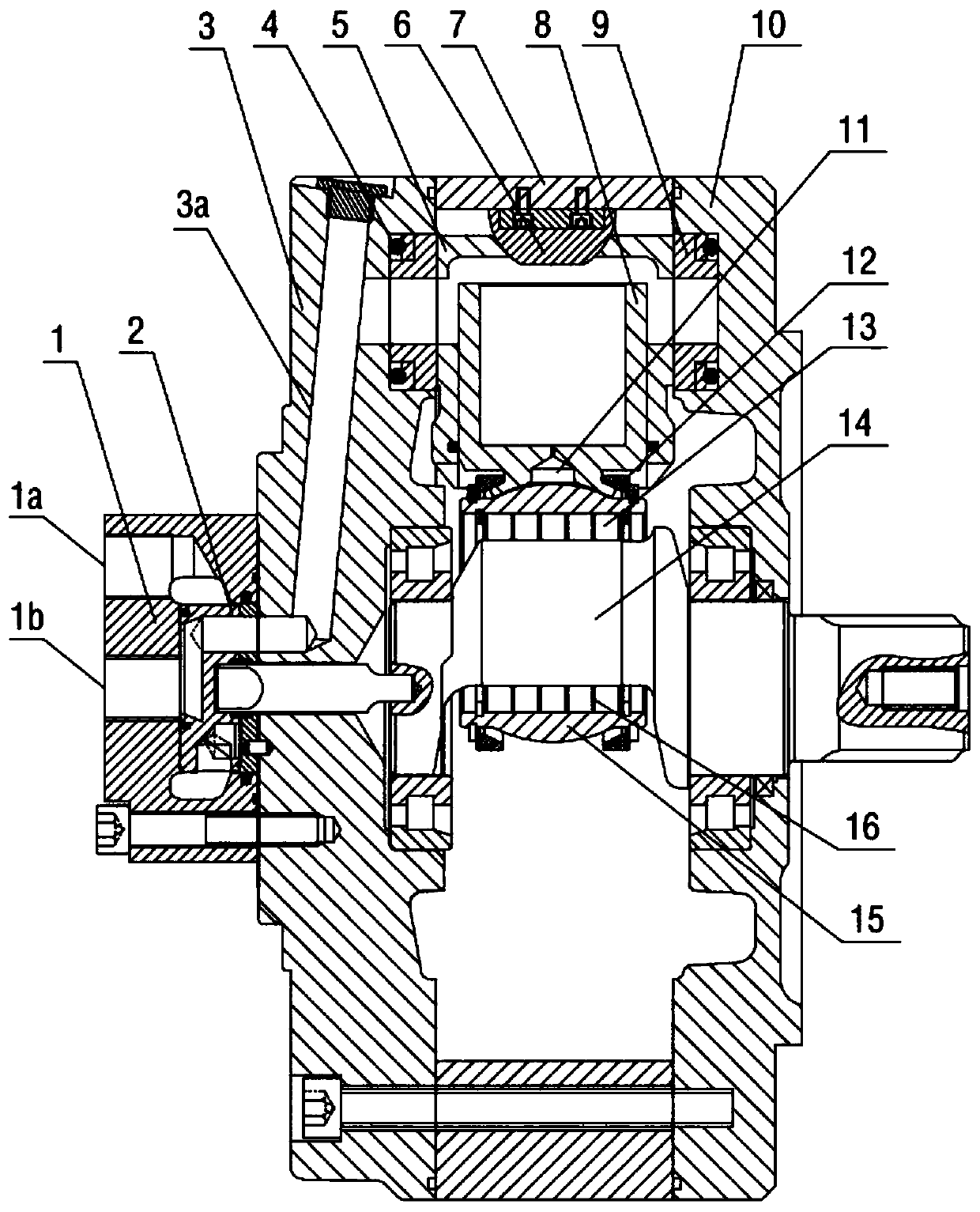

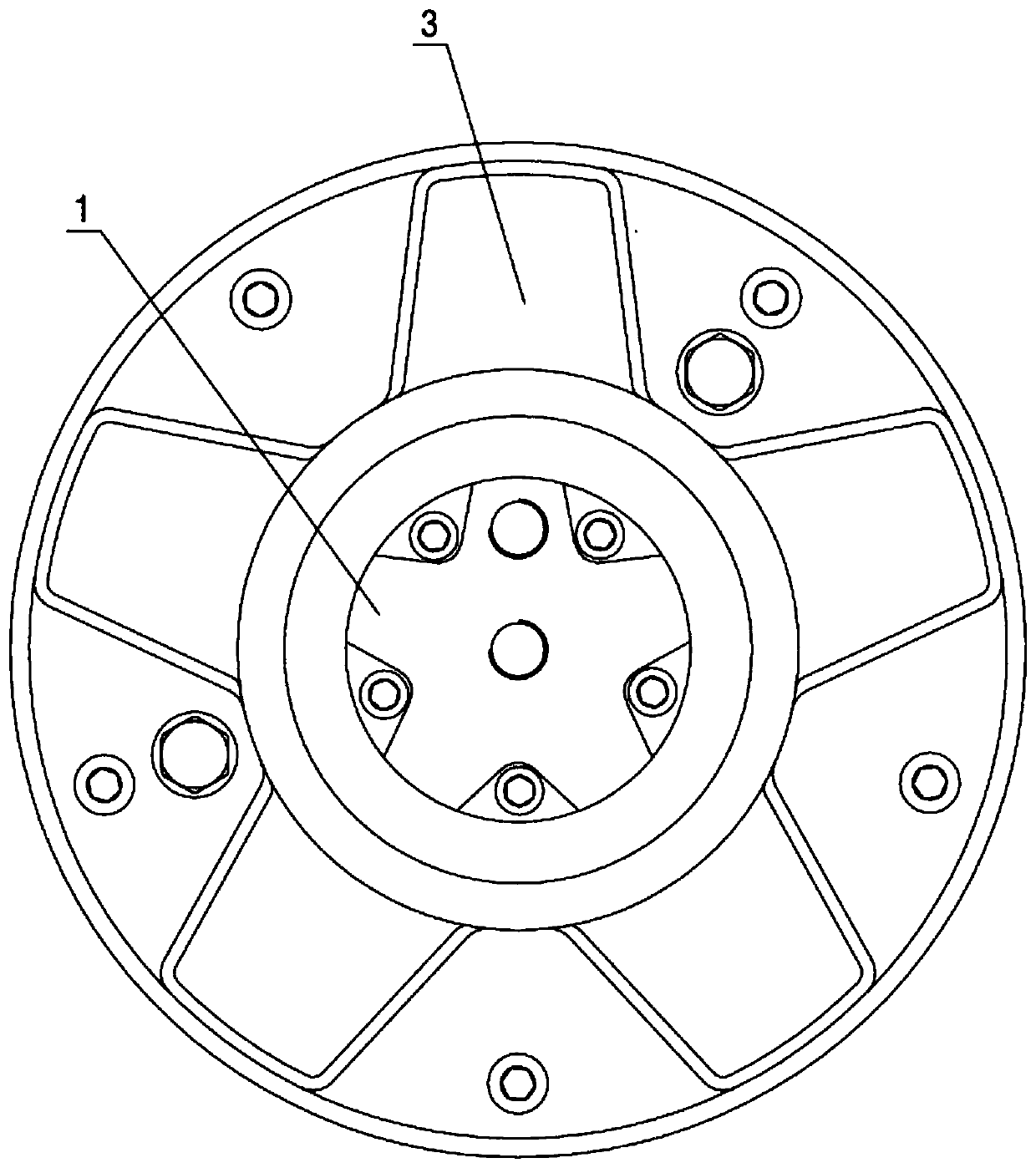

[0024] see Figure 2 to Figure 8 , a new type of swing cylinder mechanism for a hydraulic motor according to an embodiment of the present invention includes: an oil pan 1, an oil distribution mechanism 2, a rear cover 3, a swing cylinder body 5, a plunger 8, a housing 10, a transition sleeve 7, a static pressure Bearing 11, radial roller bearing 13, spherical plunger support ring 15, plunger clamping ring 12 and crankshaft 14; first oil inlet passage 1a and second oil inlet passage 1b are arranged on the oil passage 1 along the axial direction, The rear cover 3 is provided with an inclined hole 3a communicating with the first oil inlet passage 1a and the second oil inlet passage 1b, and the high-pressure oil passes through the oil pan 1, passes through the distribution mechanism 2, the inclined hole 3a of the rear cover 3, and then passes to the swing cylinder body 5, and transmitted to the plunger 8, the swing cylinder 5 and the plunger 8 are always in a centered state throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com