Waste heat recovery system of air compressor

A waste heat recovery system and air compressor technology, applied in heating systems, space heating and ventilation, heating methods, etc., can solve problems such as energy waste, improve operating conditions, reduce maintenance costs, and reduce machine failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

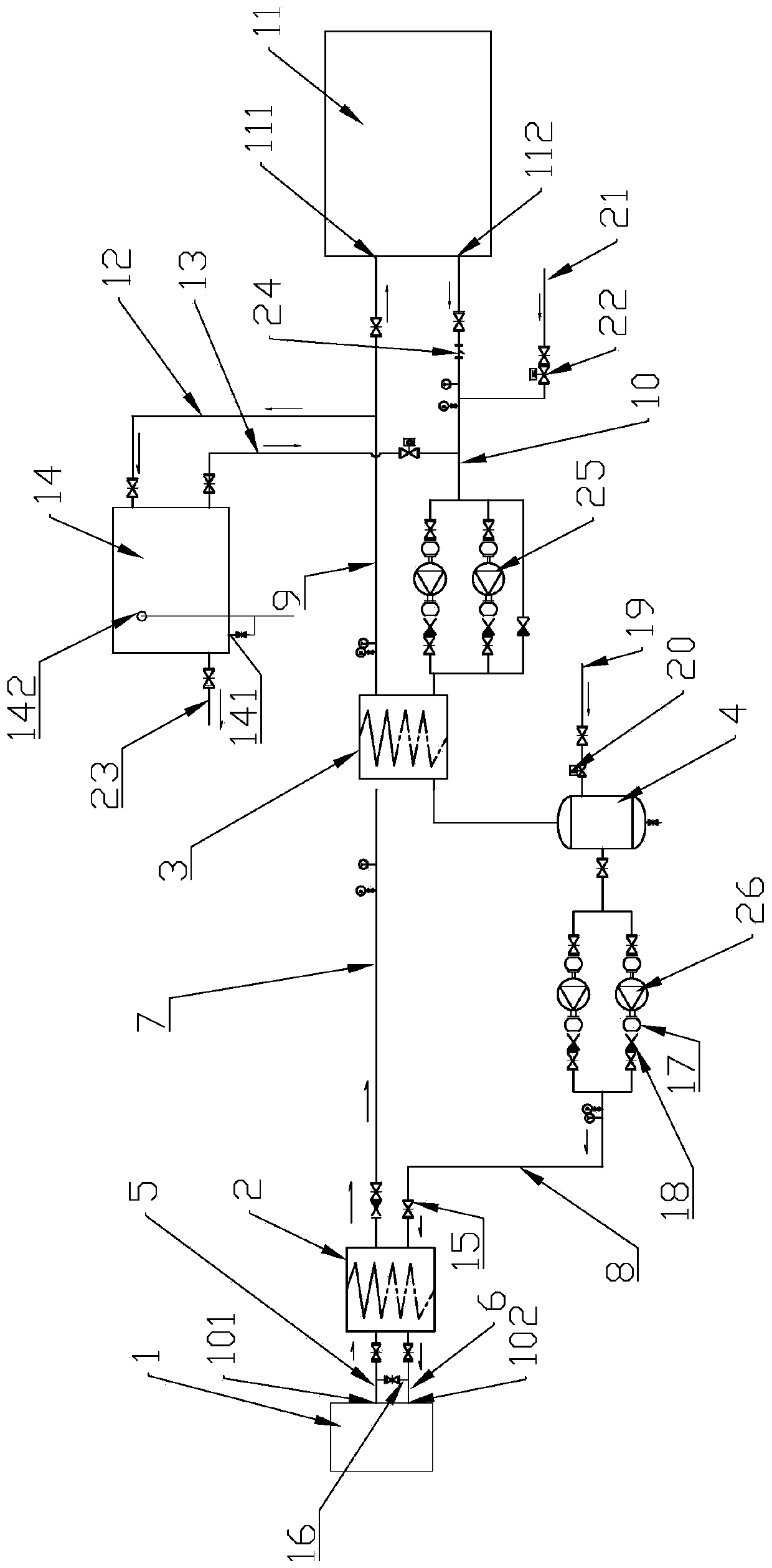

[0017] Refer to the attached figure 1 The air compressor waste heat recovery system of the present invention will be described in detail below.

[0018] The air compressor waste heat recovery system of the present invention comprises an air compressor 1, a first plate heat exchanger 2, a second plate heat exchanger 3, and a buffer tank 4, and the first plate heat exchanger 2 passes through the first pipeline 5. The second pipeline 6 is connected to the oil outlet 101 and the oil return port 102 of the air compressor 1, and is connected to the second plate heat exchanger 3 through the third pipeline 7 and the fourth pipeline 8. The first pipeline 5 communicates with the second pipeline 6, the third pipeline 7 communicates with the fourth pipeline 8, the buffer tank 4 is arranged on the fourth pipeline 8, the second plate heat exchanger 3 passes through the fifth pipeline 9, the sixth The pipeline 10 is connected to the water supply port 111 and the water return port 112 of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap