Rotary detonation combustion chamber capable of realizing observation of flow field structure of isolation section

A technology of combustion chamber and isolation section, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., to achieve the effect of stable airflow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

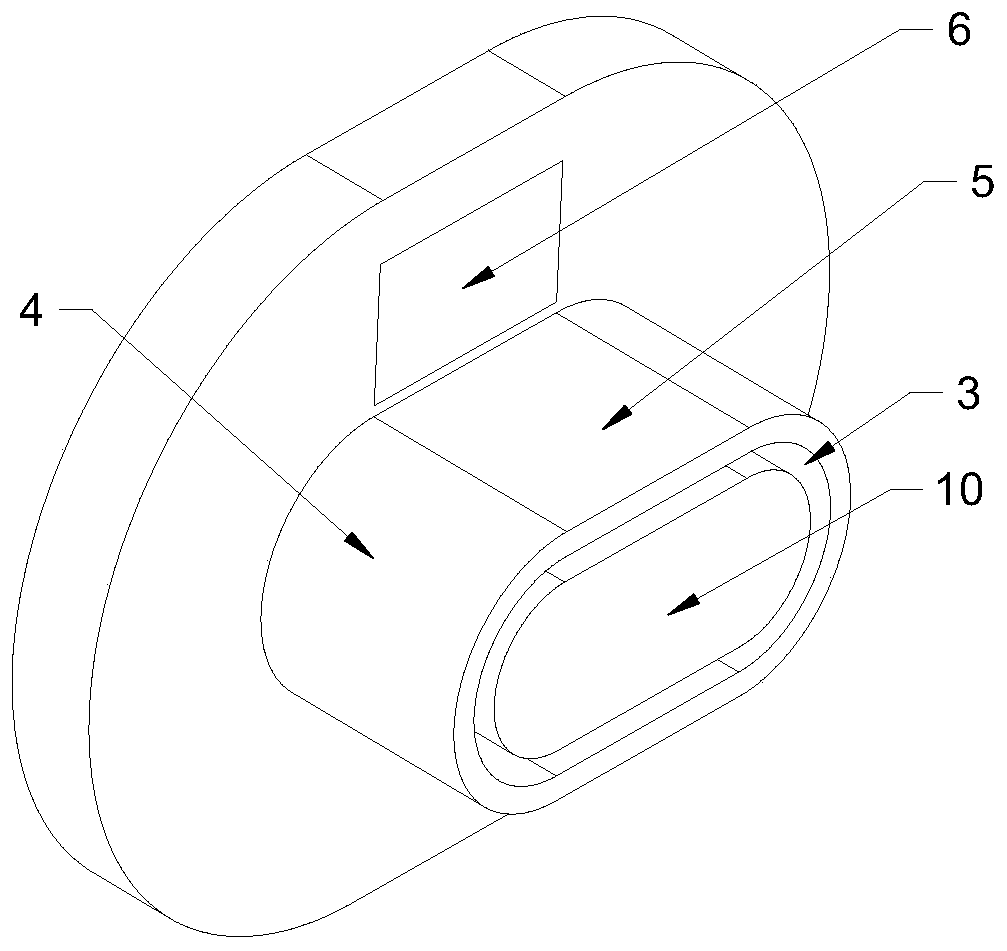

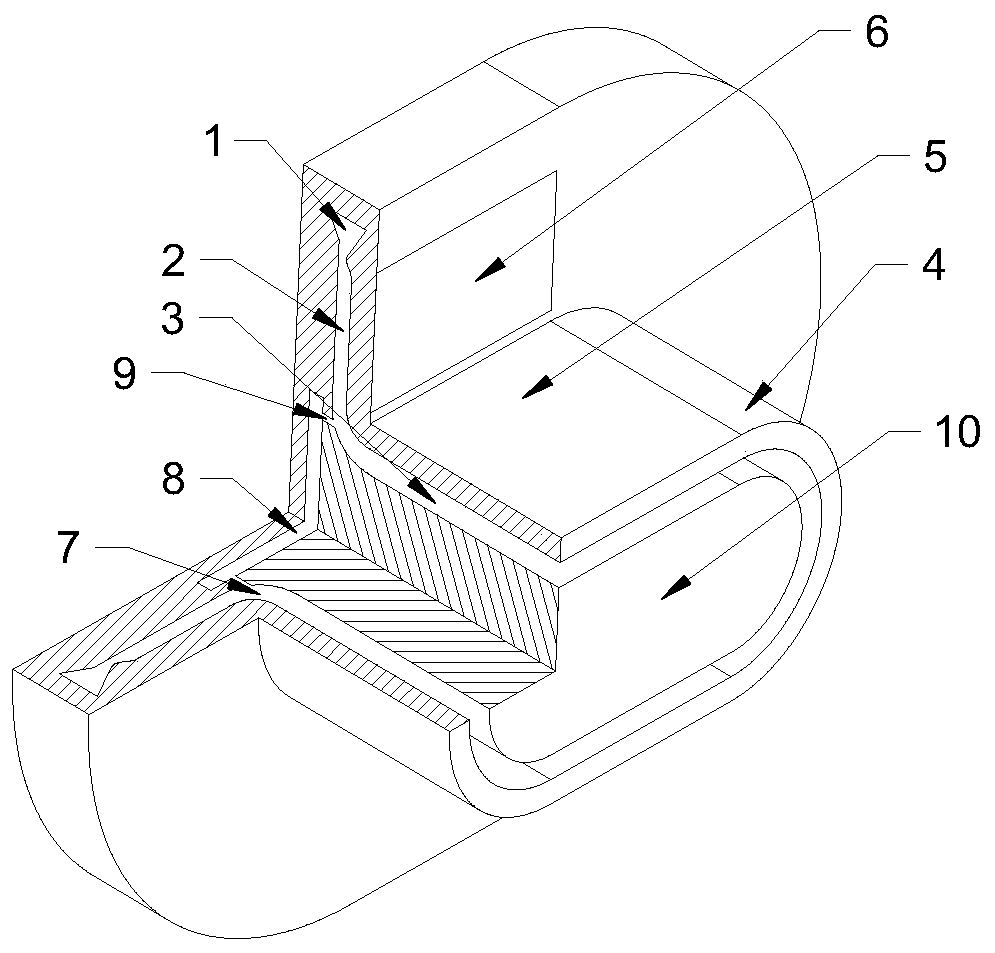

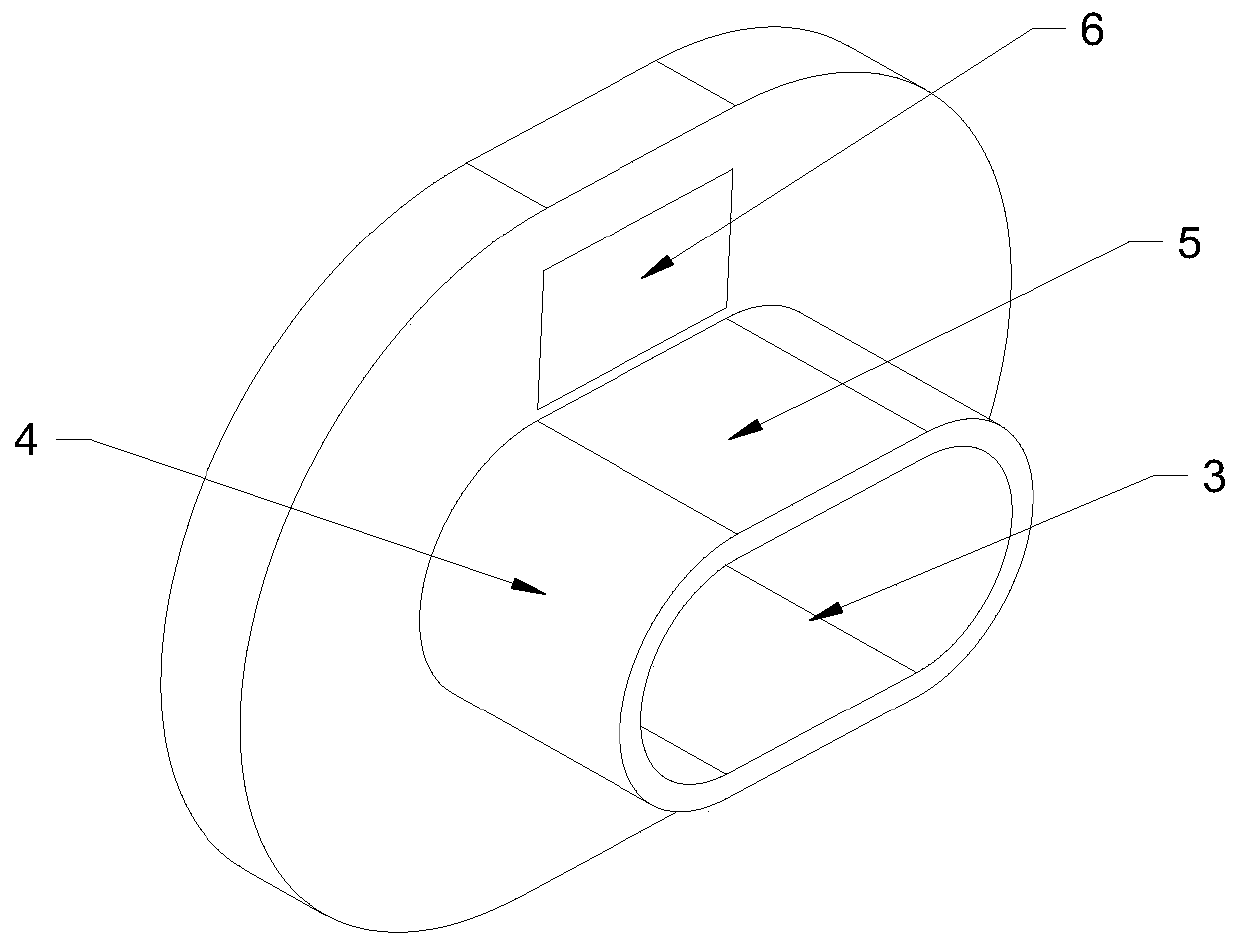

[0023] see figure 1 , figure 2 with Figure 7 , a rotary detonation combustor that can realize the observation of the flow field structure in the isolation section, mainly composed of a rotary detonation combustor 3 and an intake air mixing module arranged at the inlet end of the rotary detonation combustion chamber 3, the intake air mixing module and The central axis of the rotary detonation combustion chamber 3 is vertical; the cross section of the rotary detonation combustion chamber 3 is mainly a runway formed by two opposite semicircular parts 4 and a racetrack-shaped equal straight section 5 connecting the two semicircular parts 4 type structure; the intake mixing module is a hollow interlayer structure, including a radial raceway-type intake section 1, a radial raceway-type isolation section 2 and a fuel injection module located on the same central axis as the rotating detonation combustion chamber 3; The outlet end of the racetrack-type isolation section 2 communica...

Embodiment 2

[0029] see Figure 5 , Image 6 with Figure 7 , a rotary detonation combustor that can realize the observation of the flow field structure in the isolation section, mainly composed of a rotary detonation combustor 3 and an intake air mixing module arranged at the inlet end of the rotary detonation combustion chamber 3, the intake air mixing module and The central axis of the rotary detonation combustion chamber 3 is vertical; the cross section of the rotary detonation combustion chamber 3 is mainly a runway formed by two opposite semicircular parts 4 and a racetrack-shaped equal straight section 5 connecting the two semicircular parts 4 type structure; the intake mixing module is a hollow interlayer structure, including a radial raceway-type intake section 1, a radial raceway-type isolation section 2 and a fuel injection module located on the same central axis as the rotating detonation combustion chamber 3; The outlet end of the racetrack-type isolation section 2 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com