Method for quantitatively characterizing content of open holes in coal

A quantitative characterization and open-pore technology, which is applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of inability to quantitatively characterize the entire area of the hysteresis loop, incomplete data, and failure to consider mercury injection pressure compression Problems such as the rule of action change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

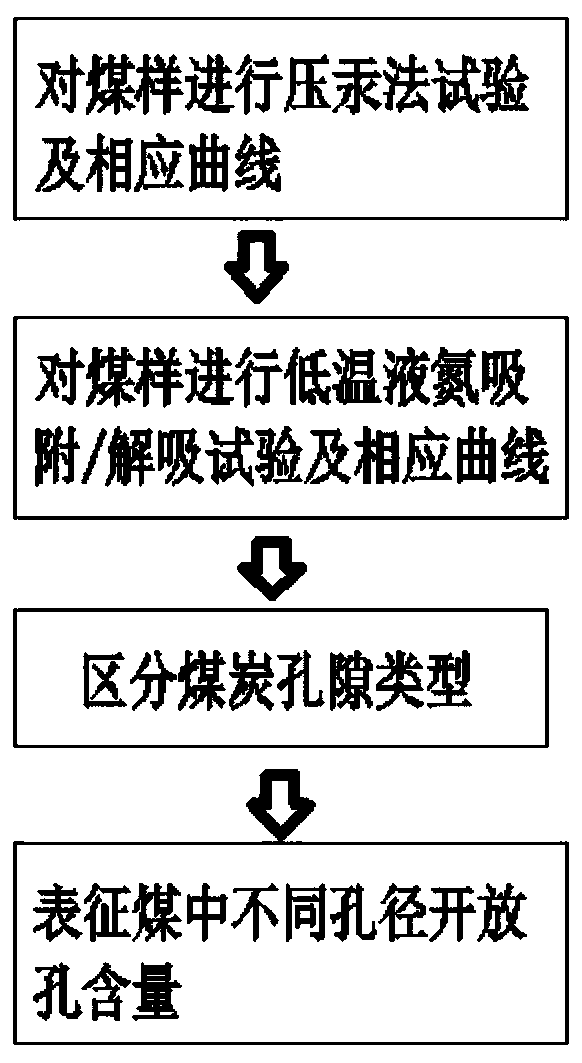

[0041] like figure 1 As shown, a method for quantitatively characterizing the open pore content in coal includes the following steps,

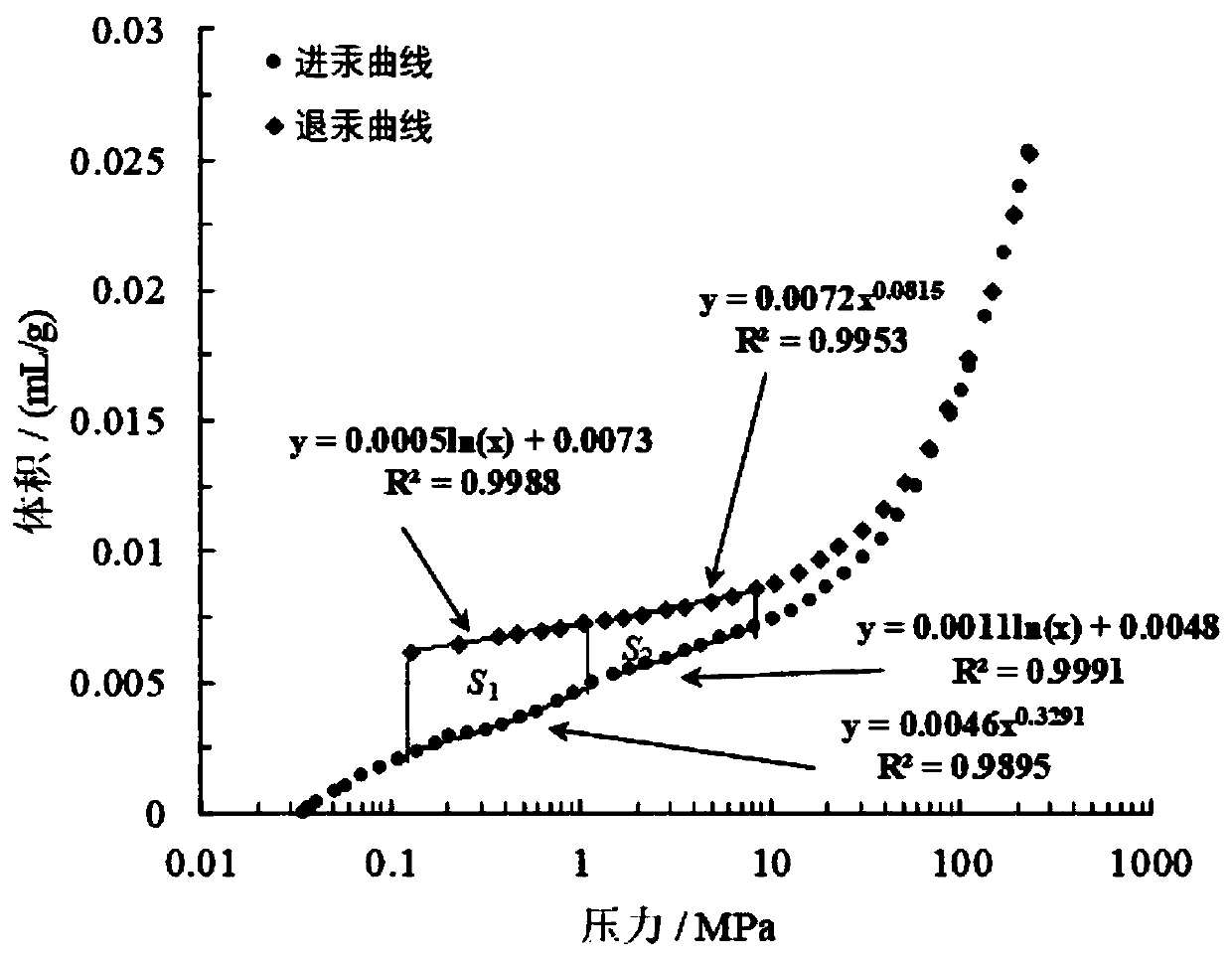

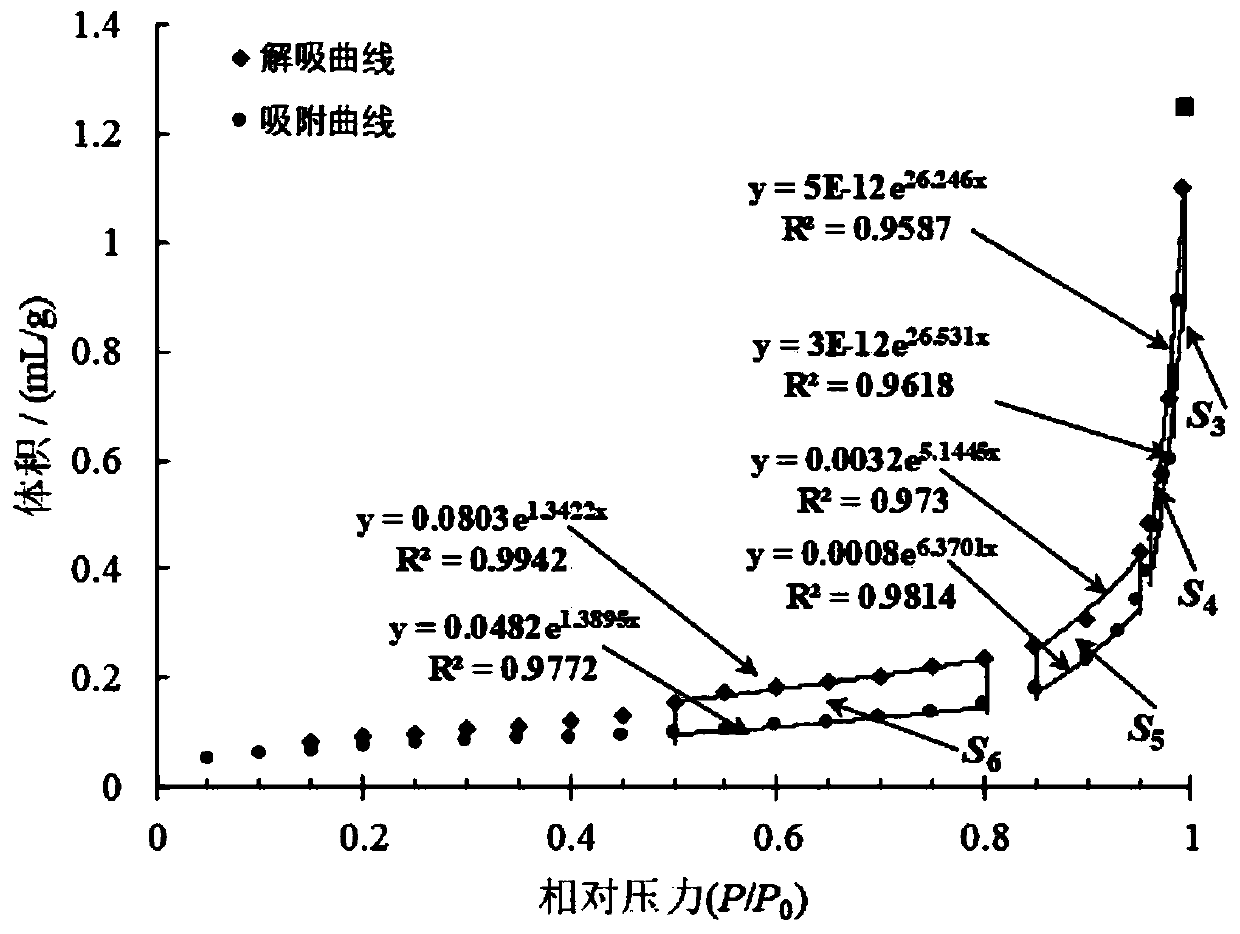

[0042] Step 1: Carry out the mercury porosimetry test on the collected coal samples. The test uses the AutoPore-IV9500 automatic mercury porosimeter, and the test is carried out in accordance with the Chinese oil and gas industry standard SY / T 5346-2005. The test uses pure coal, which is uniformly broken into 1 -2mm; Before the test, the sample is dried to a constant weight in a drying oven, and then tested. During the test, the mercury injection pressure range of the instrument is 0.034-227.5MPa, and the corresponding pore diameter range is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com