A system and method for realizing real somatosensory driving of forklift simulation

A realization method, a technology for simulating driving, applied in simulators, simulators for space navigation conditions, space navigation equipment, etc., can solve the problems of complex structure and control, level of coaching, lack of uniform training standards, and low fidelity of dynamic models, etc. problem, to achieve the effect of increasing simulation fidelity and realistic driving environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] specific implementation plan

[0101] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

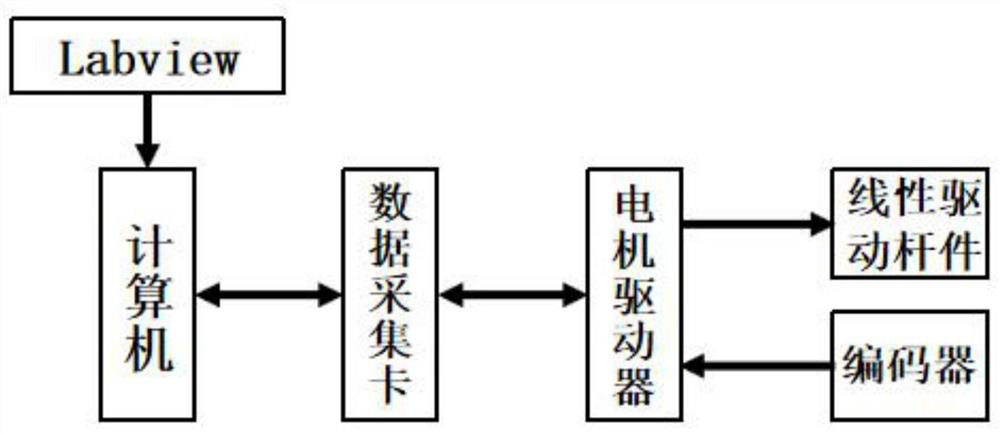

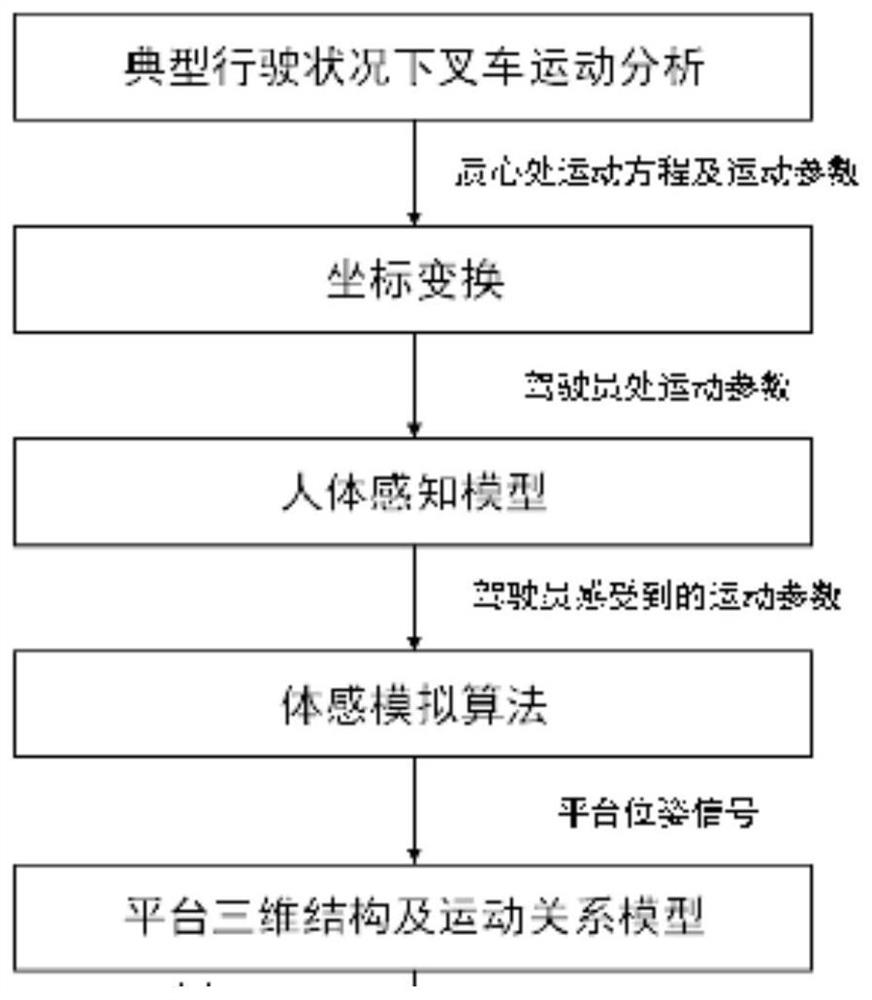

[0102] A real somatosensory realization system for simulated driving of a forklift according to the present invention includes a hardware platform and a software module.

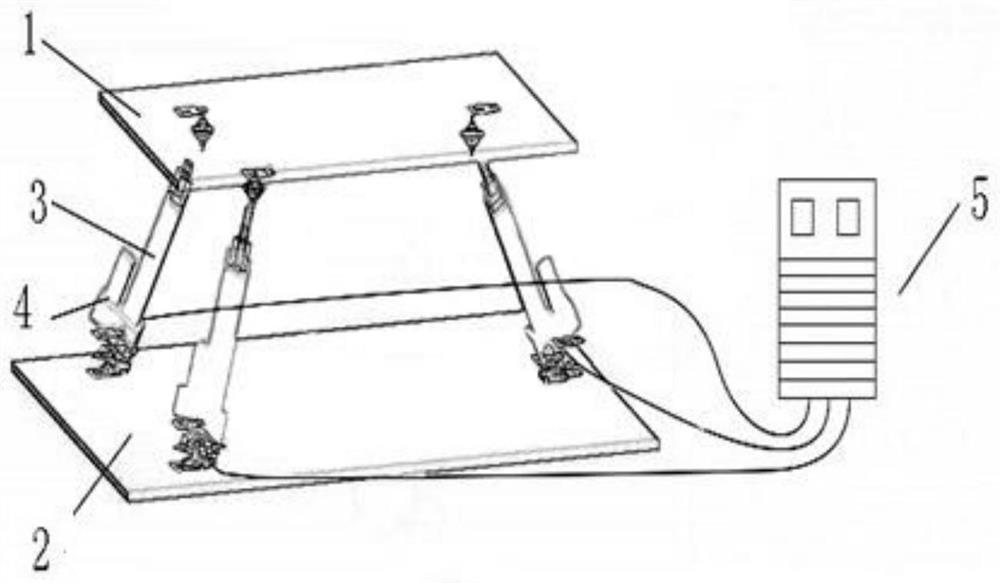

[0103] Such as figure 1 As shown, a real somatosensory realization system for simulated driving of a forklift according to the present invention, its hardware platform includes a moving platform 1, a fixed platform 2, three linear drive rods 3, a servo motor 4, and a servo motor driver 5.

[0104] Further, the moving platform 1 is connected with three linear driving rods 3 through a ball joint pair, and the upper surface is connected with the seat for out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com