Remote operation guiding system and method based on mixed reality

A remote operation and mixed reality technology, applied in the field of remote operation guidance system based on mixed reality, can solve problems such as single interaction mode, inability to accurately and intuitively express complex operation guidance intentions, and low interaction dimension, so as to relieve fatigue and reduce information Communication barriers, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

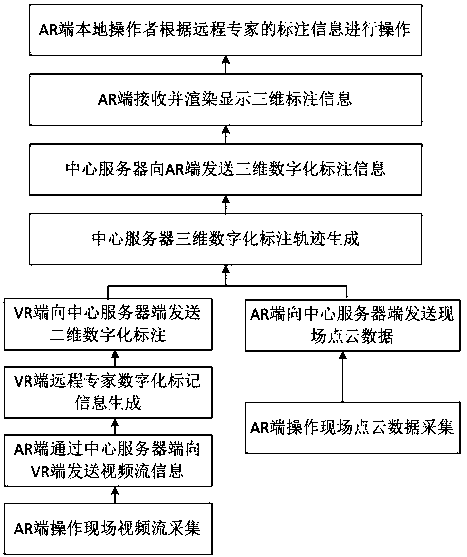

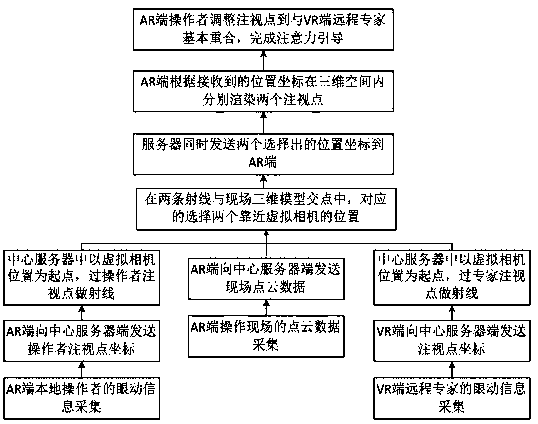

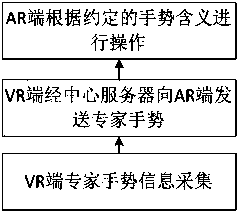

[0034] Step 1: Before the task starts, the local operator on the AR client and the remote expert on the VR client need to enter the mixed reality remote collaboration system. Then, the local operator starts the AR client, and the AR client automatically turns on the HMD camera to capture the working scene in real time At the same time, the system automatically turns on the HoloLens to obtain the local operator's gaze point and render it in the local operator's field of vision in real time, and then uses the built-in camera of HoloLens to collect on-site video and use the depth sensor to collect on-site point cloud data and gesture information;

[0035] Step 2: The remote expert starts the VR client, and at the same time, the system automatically starts the aGlass-DK2 eye tracker, LeapMotion, and HTC VIVE helmet to collect the remote expert's eye movement information and gesture information;

[0036] Step 3: Turn on the central server and connect to the network to test that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com