Magnetic medium auxiliary tailor-welded blank drawing forming device and forming method

A technology of magnetic media and tailor-welded blanks, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult regulation, distortion, cracking, and wrinkling, and achieve the effect of enriching the technical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

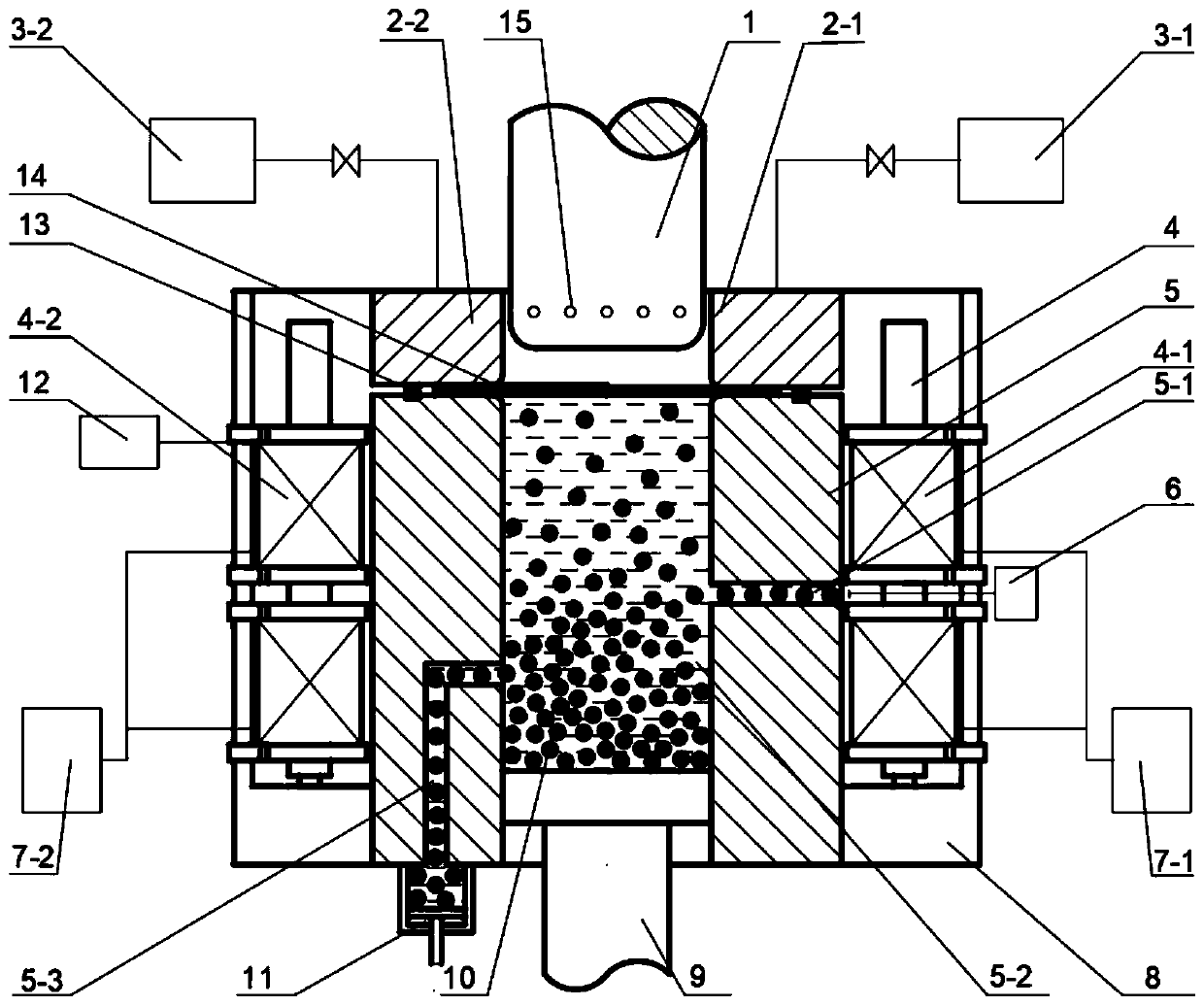

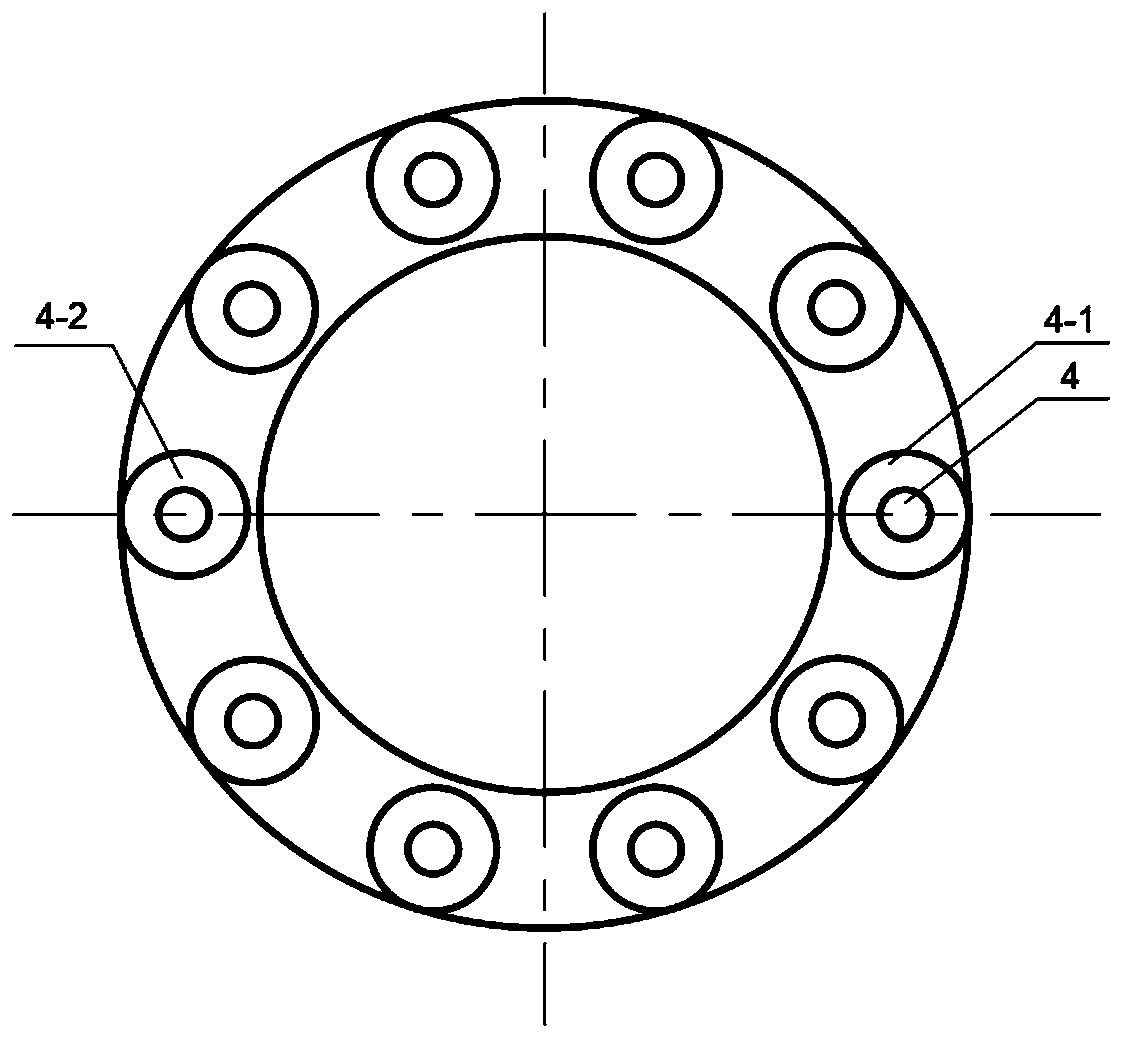

[0046] Specific implementation mode one: combine Figure 1-9 Describe this embodiment, this embodiment includes punch 1, first block blank holder 2-1, second block blank holder 2-2, first hydraulic control system 3-1, second hydraulic control system 3 -2, mandrel 4, first sliding coil group 4-1, second sliding coil group 4-2, die 5, pressure relief system 6, first controller 7-1, second controller 7-2, Support 8, plunger 9, magnetic medium 10, magnetic medium injection cylinder 11, cooling device 12 and Hall sensor 15; the first segmented blank holder 2-1 and the second segmented blank holder 2-2 are located The outer circumference of the punch 1 is controlled by the first hydraulic control system 3-1 and the second hydraulic control system 3-2 respectively. Several Hall sensors 15 are arranged in the punch 1, and the die 5 is located at Below the first segmented blank holder 2-1 and the second segmented blank holder 2-2, and they are arranged facing up and down, the outer pe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap