A fluid shear type metal parts surface derusting device

A technology of fluid shearing and components, which is applied in the direction of explosion generating devices, metal processing equipment, abrasive feeding devices, etc., can solve the problems of uncleaning of rust removal devices, large water consumption, high price, etc., and improve metal rust removal Effects, effects that increase the chance of contact collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

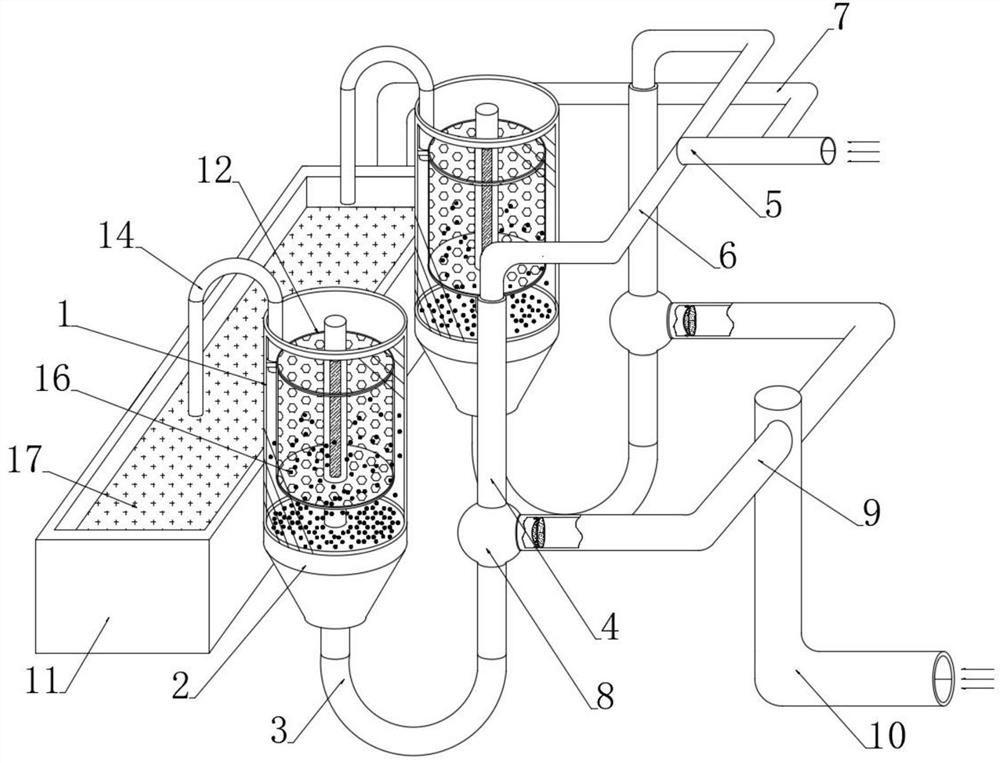

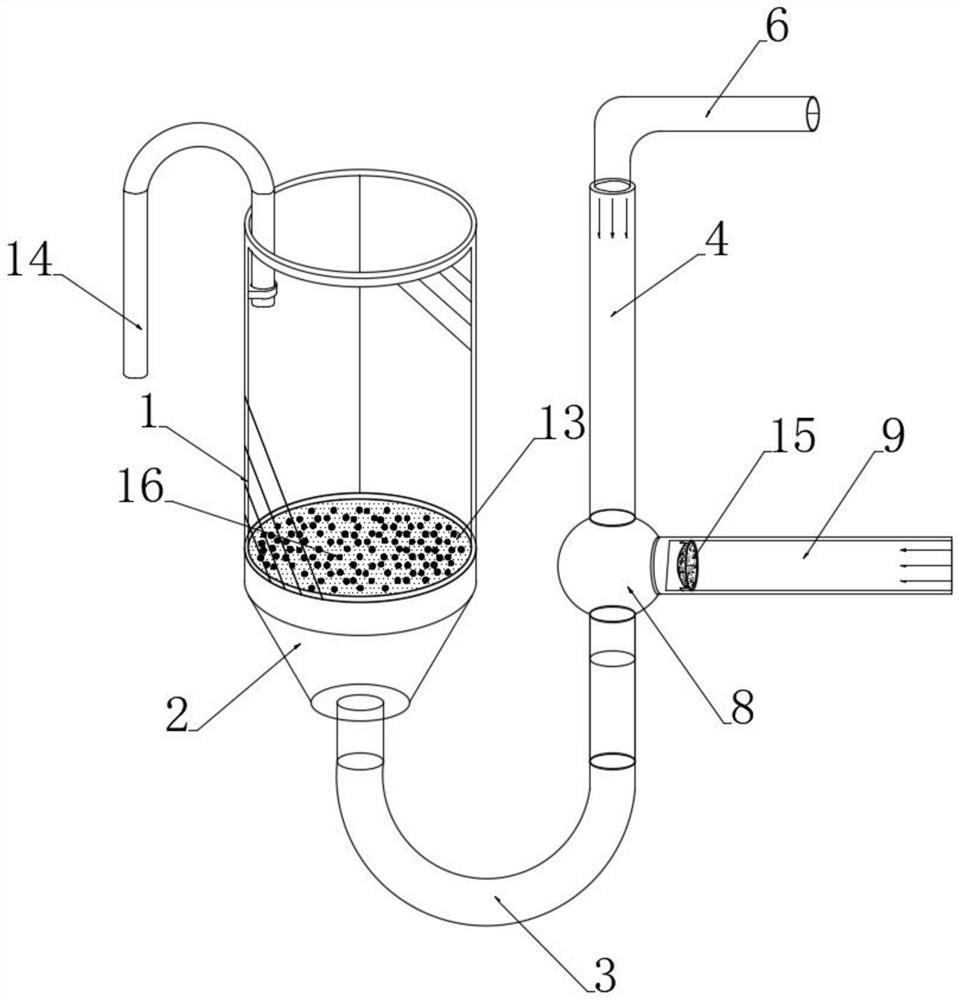

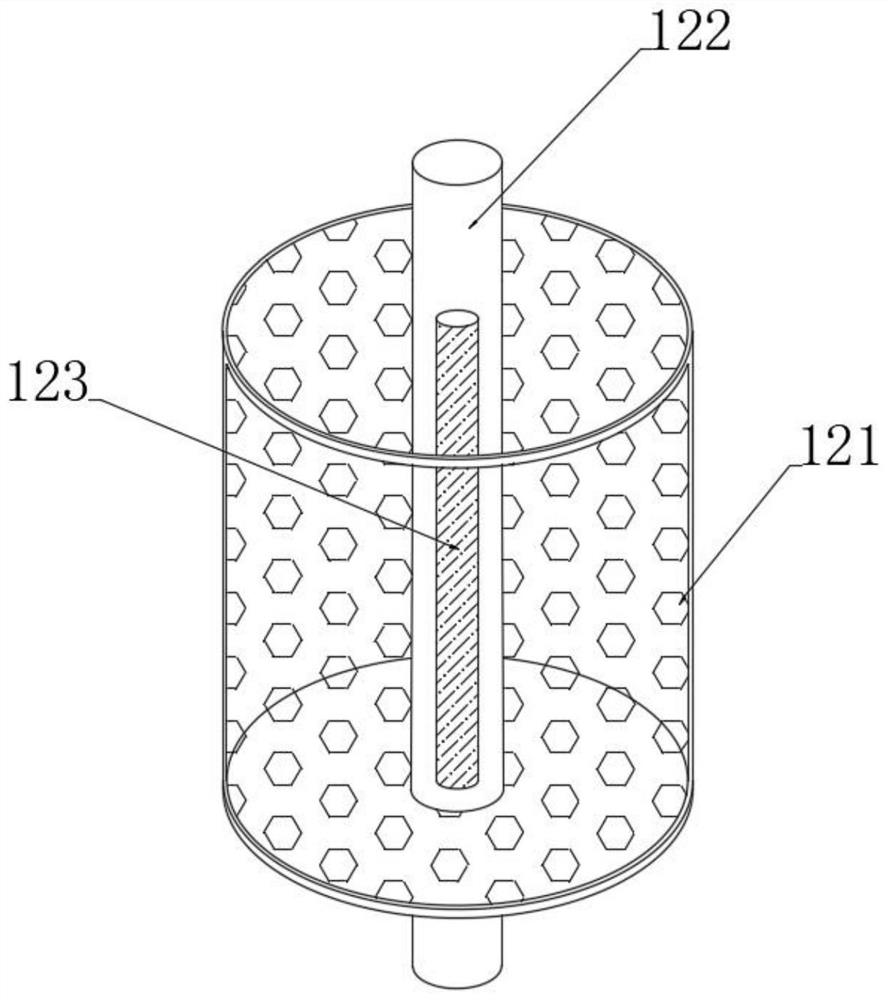

[0037] see Figure 1-2 , a fluid shearing rust removal device for the surface of metal parts, comprising multiple groups of fluid shearing derusting cylinders 1, the bottom ends of multiple groups of fluid shearing derusting cylinders 1 are all provided with conical impact guides 2, multiple The bottom ends of the group of conical impact diversion parts 2 are all fixedly connected with water flow impact vertical pipes 4 through U-shaped flow guide pipes 3, and multiple water flow impact vertical pipes 4 are connected by water inlet mechanisms, and multiple water flow impact vertical pipes One side of the lower end of the pipe 4 is connected by an air intake mechanism, and the top ends of a plurality of U-shaped guide pipes 3 away from the conical impact guide part 2 are fixedly connected with a spherical contact head 8, and the water inlet mechanism impacts the vertical pipe 4 and the water inlet mechanism through the water flow. The spherical contact heads 8 are connected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com