Intelligent building material environment-friendly processing assembly line

A streamlined and environmentally friendly technology, applied in wood processing appliances, manufacturing tools, woodworking safety devices, etc., can solve the problems of easy up and down shaking, inconvenient adjustment, no cutting width, etc., to achieve the effect of convenient cutting width and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

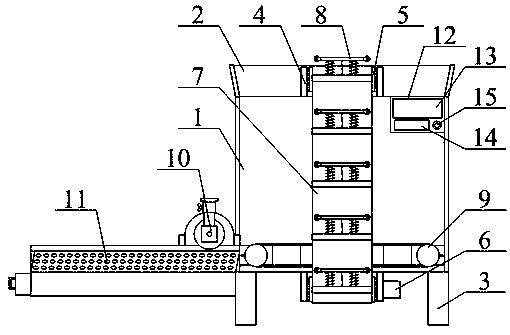

[0039] as attachedfigure 1 And attached image 3 shown

[0040] The invention provides a rectangular box body 1, a hopper 2, a longitudinal support leg 3, a longitudinal fixing plate 4, a longitudinal conveying roller 5, a longitudinal conveying motor 6, a longitudinal conveying belt 7, an auxiliary clamping frame 8, and a transverse conveying frame structure 9. Adjustable cutting frame structure 10, finished material export classification frame structure 11, control box 12, touch screen 13, controller 14 and power switch 15, described hopper 2 bolts are installed on the upper outside of rectangular box body 1; The longitudinal legs 3 are welded at the lower four corners of the rectangular box body 1; there are multiple longitudinal fixing plates 4, the longitudinal fixing plates 4 are arranged in pairs, and the longitudinal fixing plates 4 are respectively welded on the rectangular box body. The front and back sides of the upper and lower ends of the middle position of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com