Waste rubber crushing device

A waste rubber and crushing device technology, which is applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of rubber heating, crushing knife heating, rubber adhesion to the inner wall of the machine body, etc., so as to prevent obstruction and facilitate recycling Utilization, the effect of facilitating rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

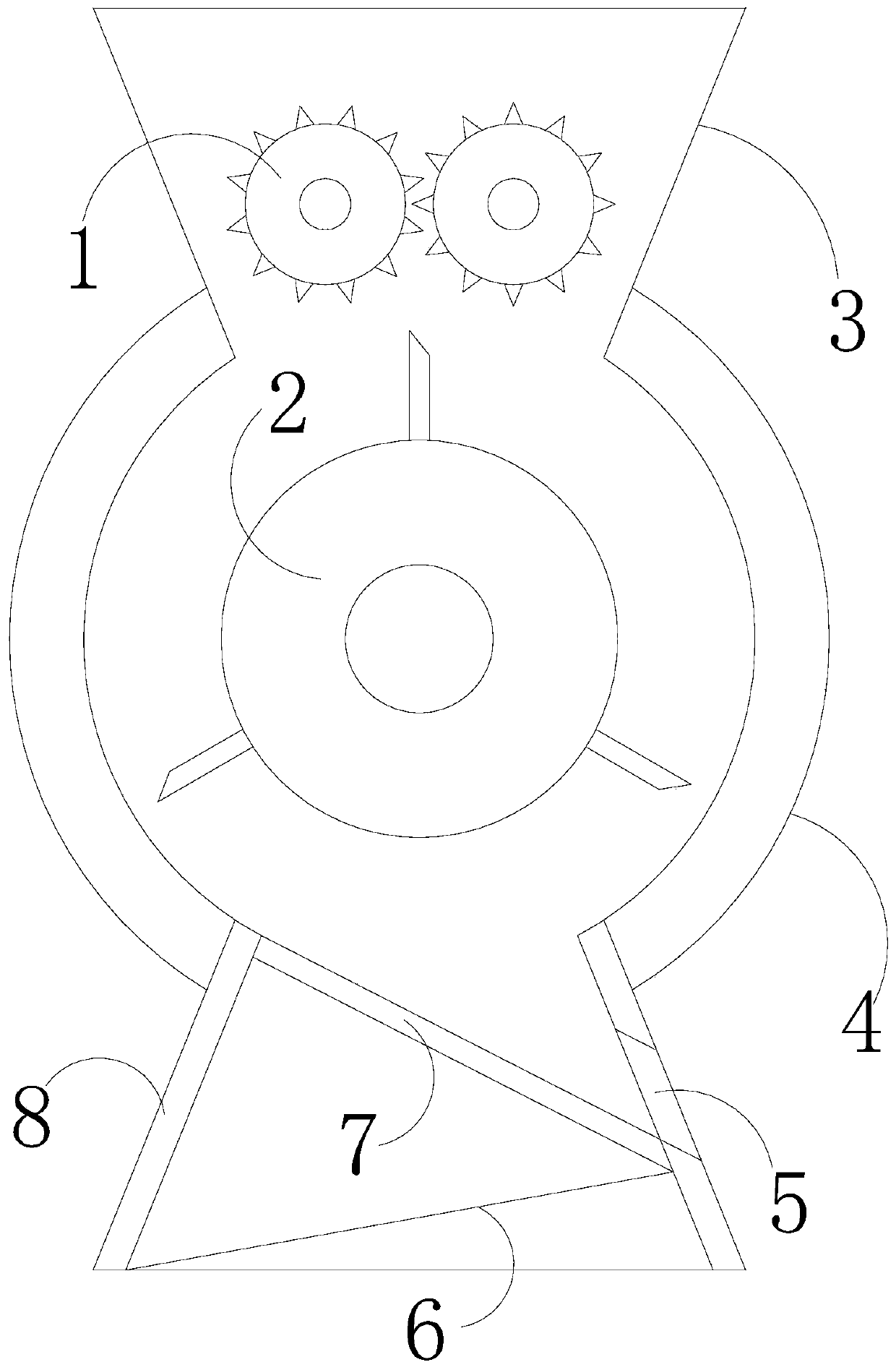

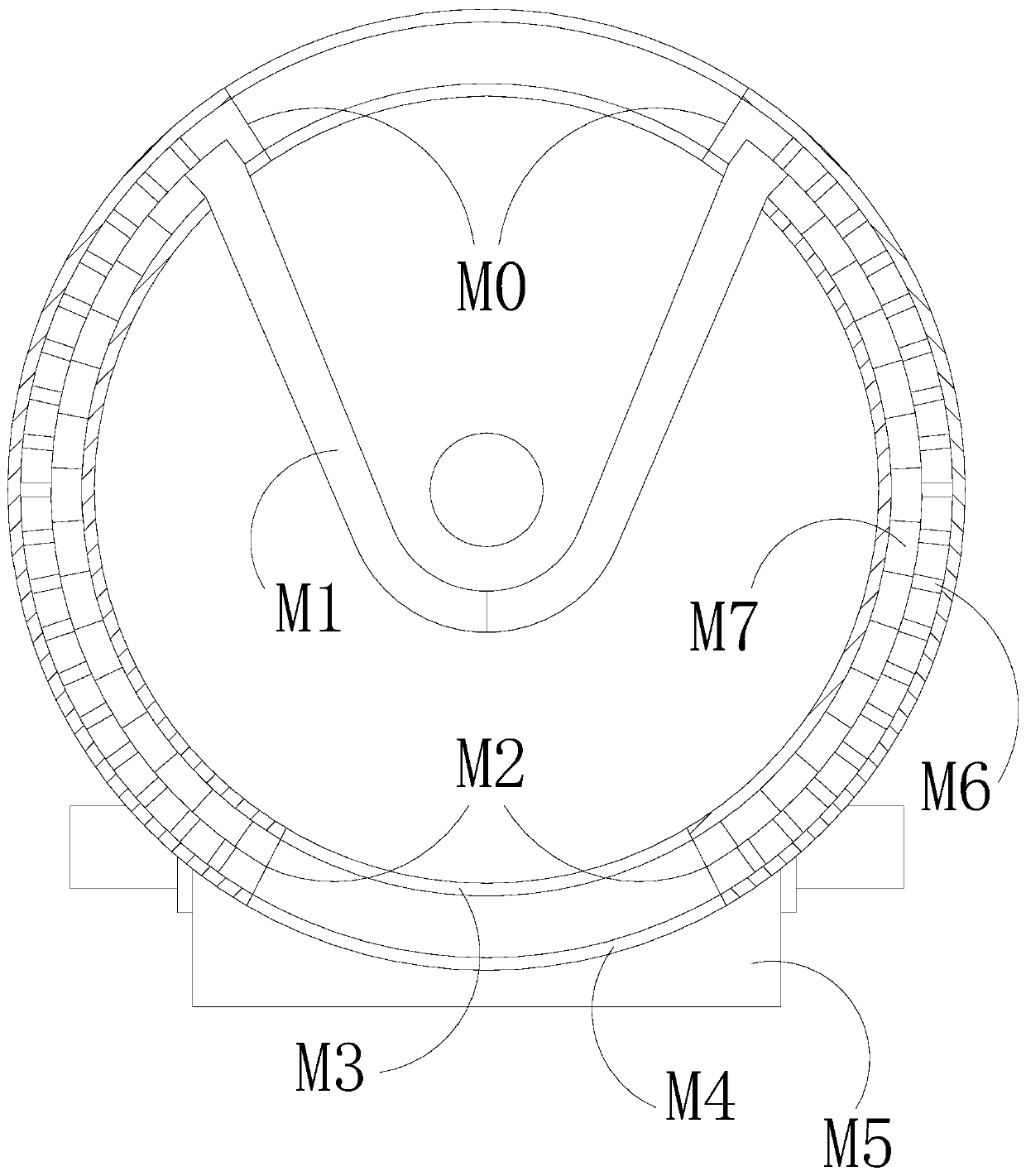

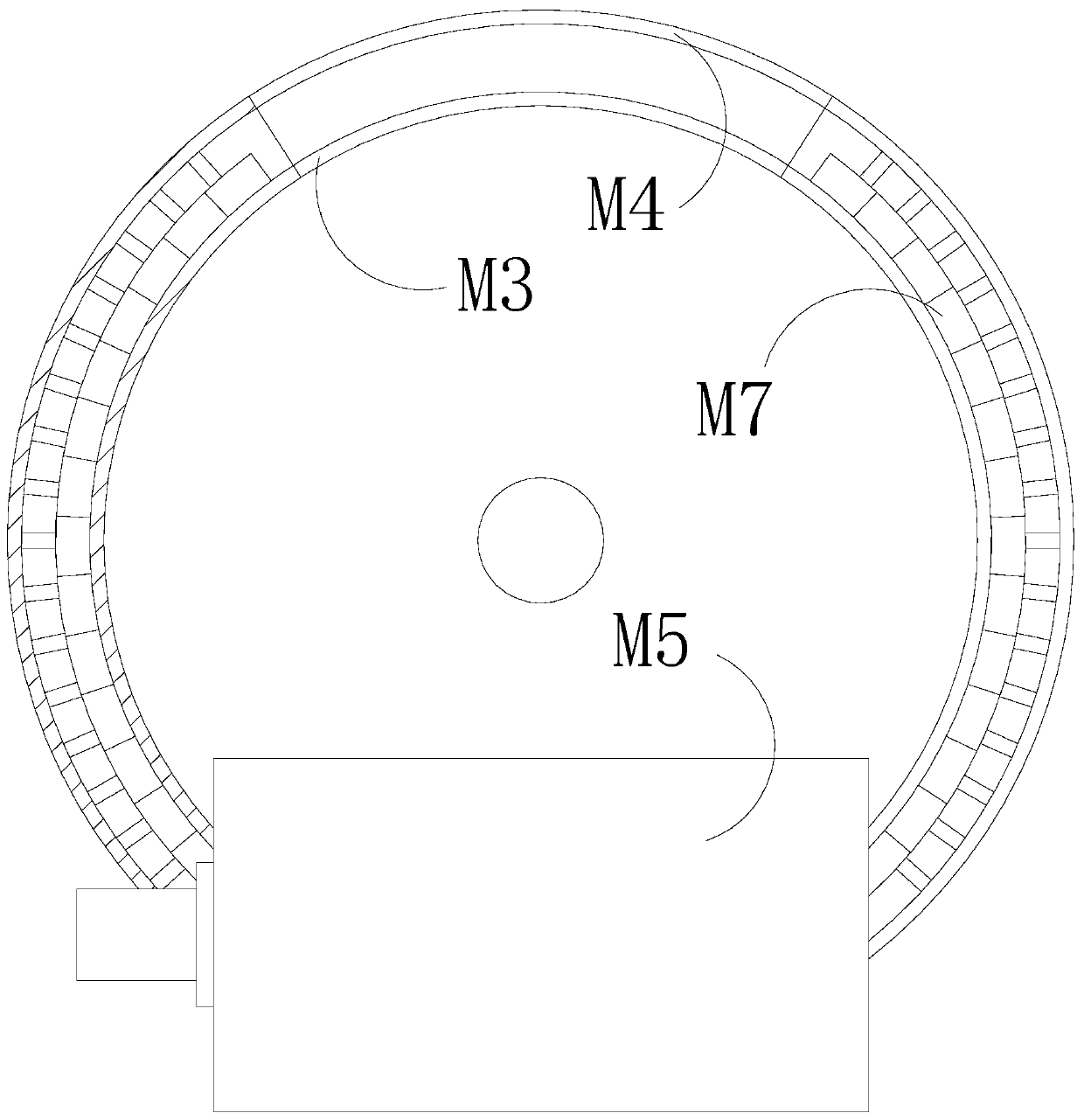

[0029] see Figure 1-5 , the present invention provides a technical scheme of a waste rubber crushing device: its structure includes a first-level waste rubber crushing mechanism 1, a secondary waste rubber crushing mechanism 2, a feeding hopper 3, a crushing machine body 4, a discharge port 5, iron filings adsorption Plate 6, metal mesh 7, base 8, the pulverizer body 4 is connected to the feed hopper 3, and the bottom is connected to the base 8, and the base 8 is built with an iron scrap adsorption plate 6 and a metal mesh 7, and the metal mesh 7 is inclined Setting, the base 8 is also provided with a discharge port 5, and the first-level waste rubber crushing mechanism 1 is arranged inside the feed hopper 3, and the second stage connected with the crushing machine body 4 is arranged below the first-stage waste rubber crushing mechanism 1. Grade waste rubber crushing mechanism 2, the setting of the iron filings adsorption plate 6 is based on the magnetic principle, which can ...

Embodiment 2

[0035] see Figure 1-8 , the present invention provides a technical scheme of a waste rubber crushing device: its structure includes a first-level waste rubber crushing mechanism 1, a secondary waste rubber crushing mechanism 2, a feeding hopper 3, a crushing machine body 4, a discharge port 5, iron filings adsorption Plate 6, metal mesh 7, base 8, the pulverizer body 4 is connected to the feed hopper 3, and the bottom is connected to the base 8, and the base 8 is built with an iron scrap adsorption plate 6 and a metal mesh 7, and the metal mesh 7 is inclined Setting, the base 8 is also provided with a discharge port 5, and the first-level waste rubber crushing mechanism 1 is arranged inside the feed hopper 3, and the second stage connected with the crushing machine body 4 is arranged below the first-stage waste rubber crushing mechanism 1. Grade waste rubber crushing mechanism 2, the setting of the iron filings adsorption plate 6 is based on the magnetic principle, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com