Cool-spreading and distiller's yeast-adding device, and method and system for cool-spreading and stacking

A conveying system and cold plate technology, which are applied in household refrigeration devices, loading/unloading, transportation and packaging, etc., can solve the problems of difficulty in controlling the uniformity of the addition and stirring, unfavorable brewing quality stability, and difficulty in controlling the temperature of distiller's grains, etc. Achieve the effect of improving the degree of automation, improving stability and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

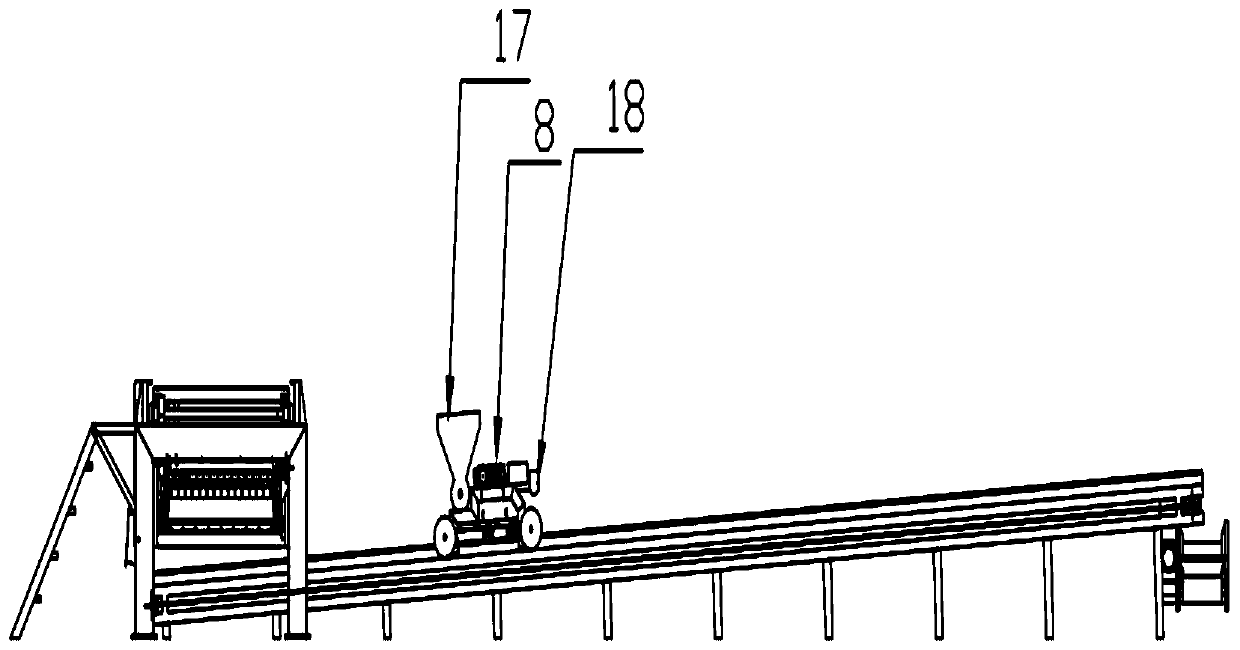

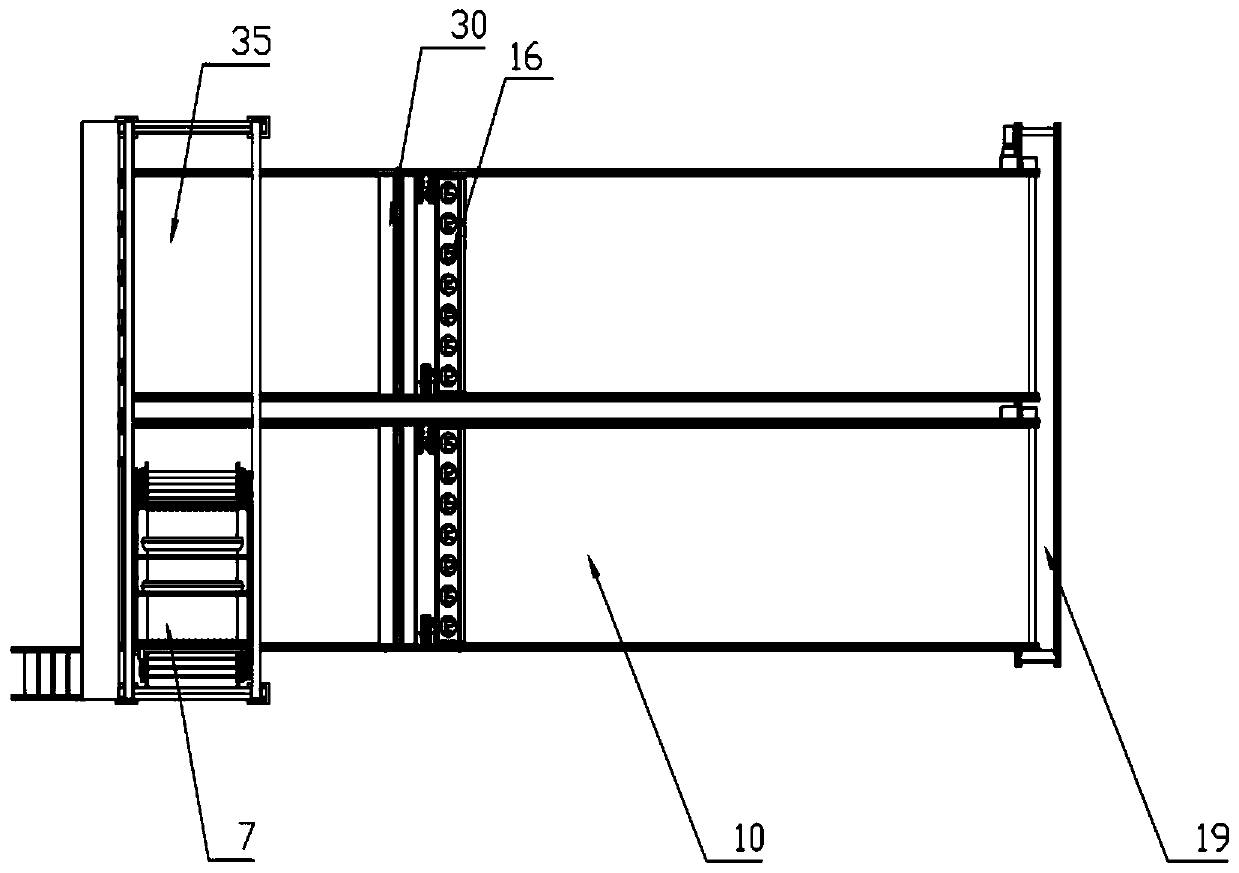

[0052] Such as figure 1 , 2 Among them, a cooling and bending device includes a sliding cooling part 8 arranged on the cooling plate 10, the sliding cooling part 8 can slide along the surface of the cooling plate 10, generally preferred, the sliding cooling part 8 is along the cooling Plate 10 slides on the long side to extend the cooling distance to the greatest extent. If the site conditions are not allowed, it can also slide along the short side of the cooling plate 10. The sliding cooling part 8 is preferably a dolly driven by electricity or pneumatics. , the cooling plate 10 is a conveyor belt, and the material of the conveyor belt is stainless steel;

[0053] Preferably, two cooling and koji spreading devices are arranged side by side, and the two cooling and koji spreading devices are evenly connected with the dispersion bin;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com