A double-roller leather processing system

A processing system and leather technology, applied in leather manufacturing, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, etc., can solve problems such as poor effect and low fat removal efficiency, and achieve shortening The effect of improving the processing cycle, improving the efficiency of degreasing, and reducing the accumulation of fat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

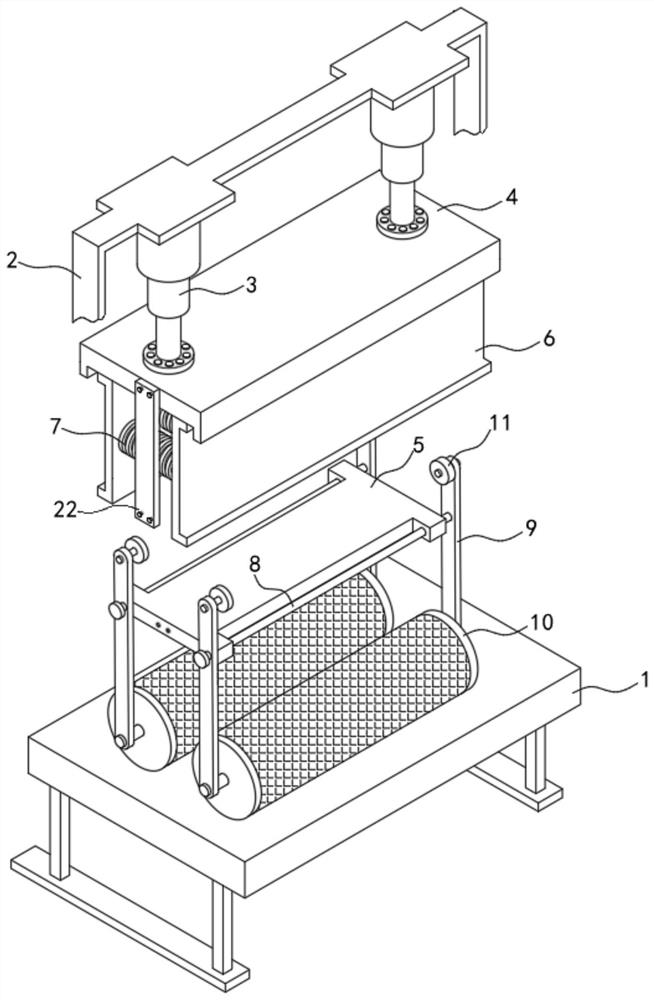

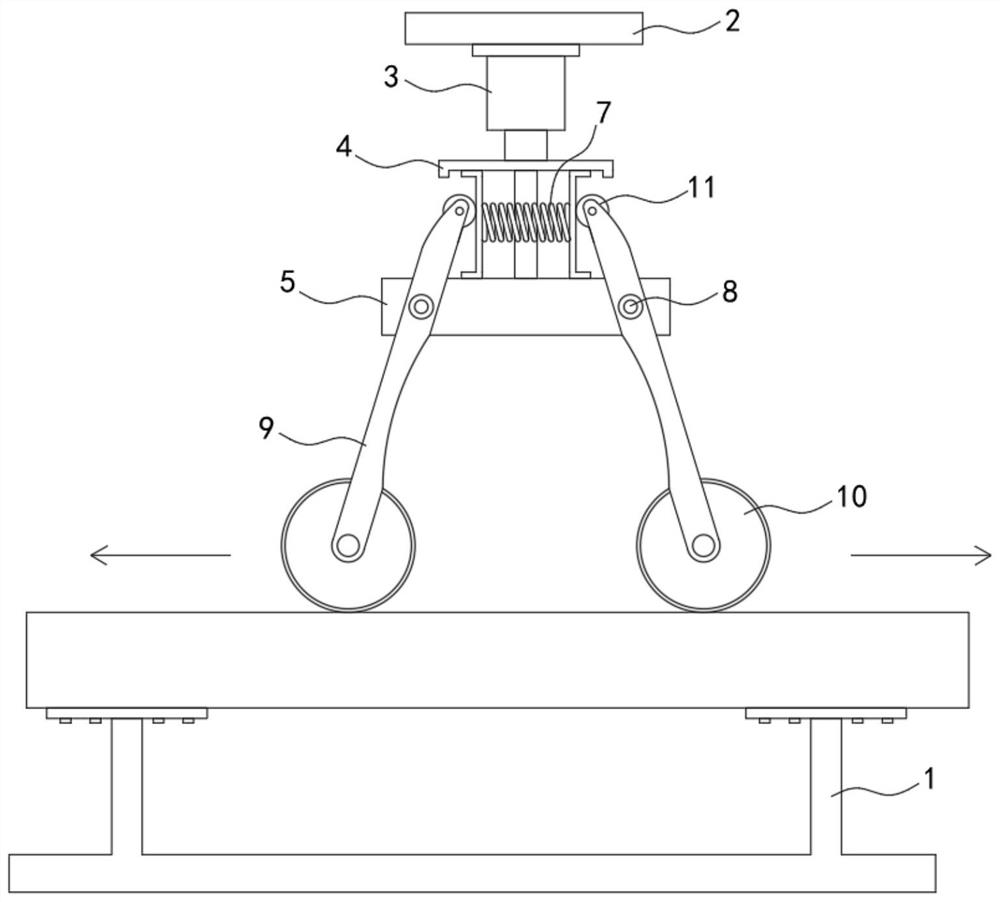

[0024] Such as Figure 1-2 As shown, a double-roller leather processing system includes a base 1, the upper end of the base 1 is fixedly connected with a fixed frame 2, the lower end of the fixed frame 2 is fixedly connected with a limiting plate 4 through a plurality of hydraulic cylinders 3, and the lower end of the limiting plate 4 passes through The connecting bar 22 is fixedly connected with a fixed plate 5, and two sliding plates 6 are slidably connected between the limiting plate 4 and the fixed plate 5. The limiting plate 4, the fixed plate 5 and the base 1 are arranged in parallel, and the two ends of the limiting plate 4 Bend downwards to form ribs for limiting the sliding plate 6 .

[0025] An elastic member 7 is fixedly connected between the two sliding plates 6, and both sides of the fixed plate 5 are rotatably connected with a rotating shaft 8, and both ends of the rotating shaft 8 are fixedly connected with a rotating rod 9, and the middle and upper parts of the...

Embodiment 2

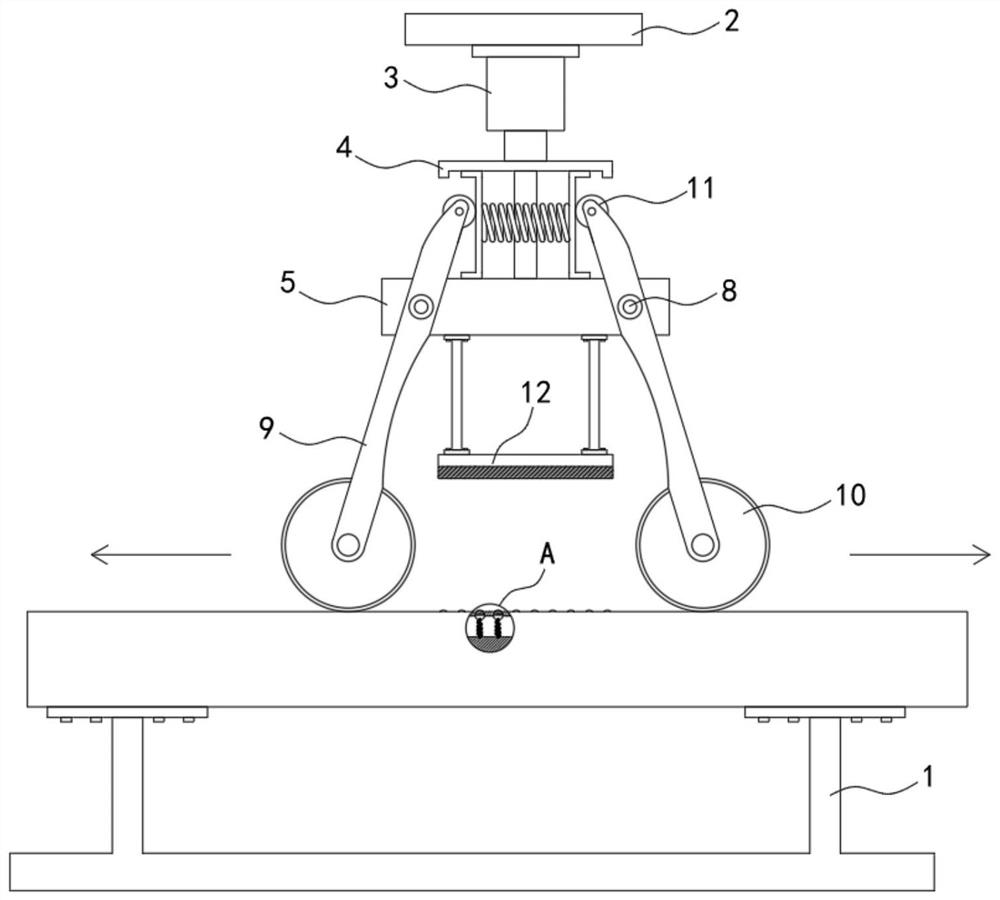

[0028] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the elastic member 7 is a plurality of return springs, and the plurality of return springs are parallel and fixedly connected between two sliding plates 6 .

[0029] The lower end of the fixed plate 5 is fixedly connected with a permanent magnet plate 12, the base 1 is provided with a cavity 13, and the upper end array of the cavity 13 has a plurality of striking holes 14, and the striking holes 14 are provided with magnetic striking balls 15, and the striking balls 15 Repel with the same polarity between the permanent magnet plates 12, and the batting ball 15 is fixedly connected with the bottom of the cavity 13 through the vibrating spring 16.

[0030] When this embodiment is in use, along with the continuous downward movement of the limiting plate 4, under the action of the magnetic field of the permanent magnet plate 12, the hitting ball 15 will be moved downward, the vibra...

Embodiment 3

[0032] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the elastic member 7 is an elastic airbag 17, and the inside of the elastic airbag 17 is sealed, and the elastic airbag 17 can be made of solvent-resistant rubber, and the elastic airbag 17 is fixed on two pieces. Between the sliding plates 6 , the elastic airbag 17 expands and contracts along the sliding direction of the sliding plates 6 .

[0033] The elastic airbag 17 is connected with a one-way liquid inlet pipe 18 and a one-way liquid discharge pipe 19. Specifically, the middle part of the elastic airbag 17 is fixedly connected with a fixed ring, and the fixed ring divides the elastic airbag 17 into two, and the one-way liquid inlet Both the pipe 18 and the one-way liquid discharge pipe 19 are fixedly connected to the fixed ring. When the elastic airbag 17 is stretched or compressed, the position of the fixed ring remains unchanged. The one-way liquid inlet pipe 18 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com