Laser cladding powder feeder

A technology of laser cladding and powder feeder, which is applied in the direction of metal material coating process and coating, which can solve the problems of poor heating uniformity, unevenness, and inability to disperse clusters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] People with a little common sense in life can understand that for powder, if it is discharged from a pipeline, the powder will eventually form a pile, and the pile will eventually block the pipeline, and the powder will not continue to go down. The size of the stockpile is positively related to the distance between the bearing surface carrying the material and the discharge port of the pipeline.

[0034] In addition, there is also a certain relationship between the size of the stockpile and the feeding pressure. In principle, the size of the stockpile is also positively related to the feeding pressure.

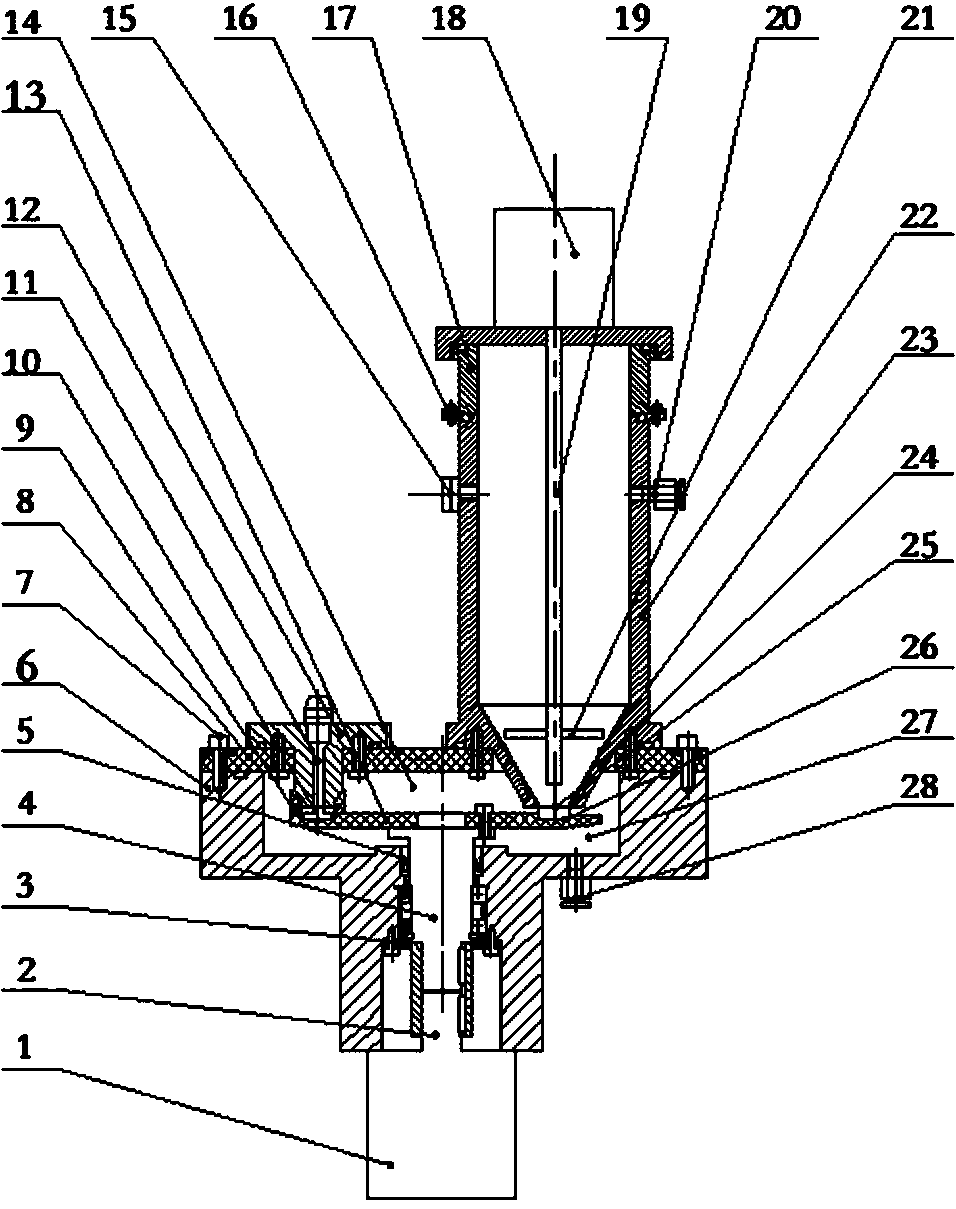

[0035] In the embodiment of the present invention, based on another fact, the relationship between the accumulation of materials and the size of the discharge aperture is relatively weak, but another aspect is as follows: figure 1 The flow diameter of the middle and lower powder nozzle 25 can be relatively large to improve the responsiveness of the feeding speed, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com