Coal mine gas test monitoring device and method

A monitoring device, a technology for coal mine gas, applied in mining devices, mining equipment, earthwork drilling, etc., can solve the problems of inaccurate monitoring and limited working area, and achieve the effect of small and precise structure, easy remote observation, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

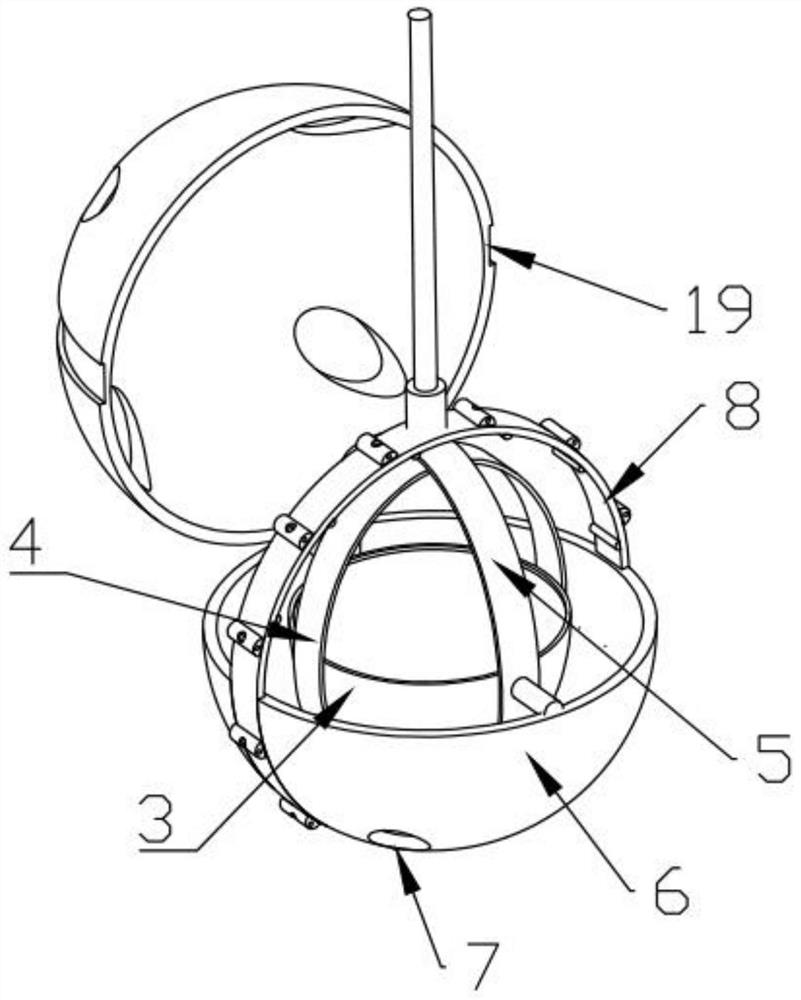

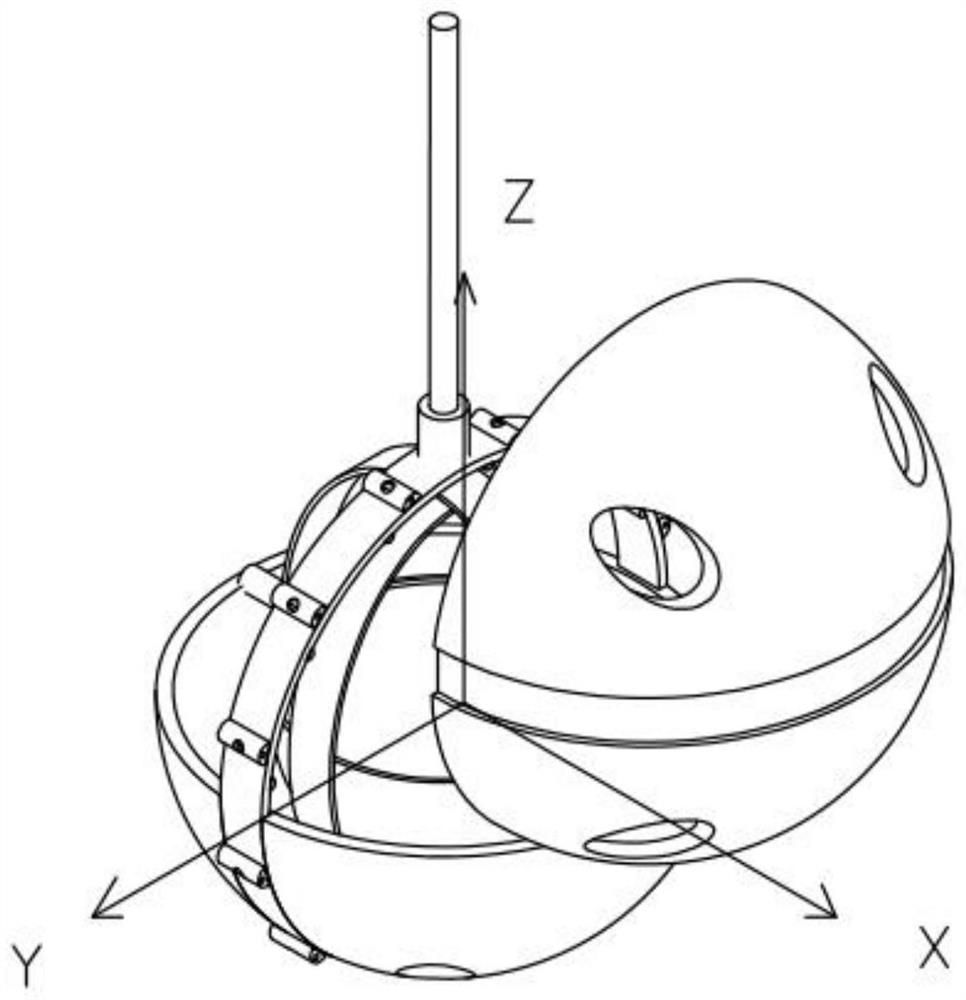

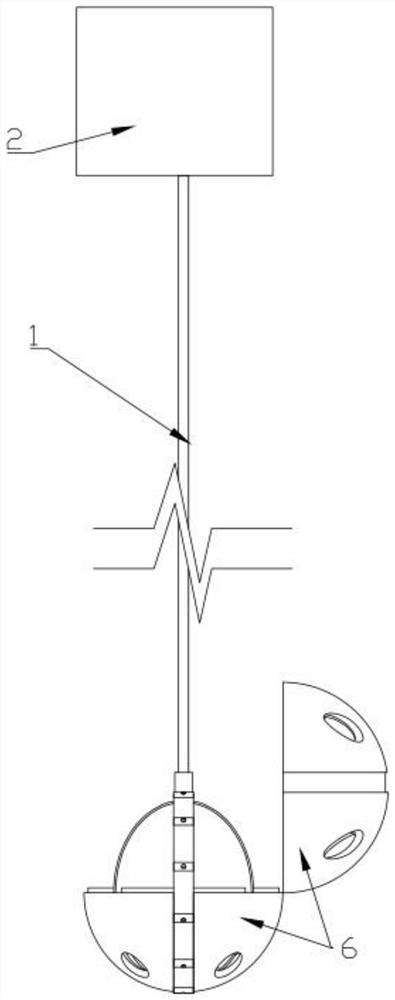

[0042] A coal mine gas test monitoring device and method, see Figure 1 to Figure 12 , including the ventilation pipe that can be installed into the ventilation pipeline of the mine entrance, the monitoring mechanism 2 and the detection ball 12 are installed at both ends of the pull rope 1, and the circuit connection is set in the pull rope 1 to connect the monitoring mechanism 2 and the detection ball. 2 Including display screen, information storage terminal;

[0043] The center of the detection ball 12 is provided with a hollow hemispherical equipment mounting shell 3, the center of the mounting shell is the center of the Cartesian coordinate system, the two horizontal directions are the X and Y directions, and the axis in the vertical direction is Z. In the direction, the equipment mounting shell 3 is covered with an elliptical X-axis reset hub 4, the horizontal axis of the X-axis reset hub 4 coincides with the centerline of the equipment mounting shell 3 in the X direction...

Embodiment 2

[0058] The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that, in this embodiment, dynamic detection may also be included. After step (2), the rolling mechanism is used to realize the remote control of the detection ball 12 to roll to the depth of the mine. close to reduce the influence of the air duct on the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com