Sliding mechanism of surface treatment equipment for synthesizing and processing new polymer material

A technology of surface treatment and sliding mechanism, which is used in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of difficult lubricating oil addition, time-consuming and laborious lubricating oil addition, and difficulty in clamping and fixing new materials, and achieves fast clamping. fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

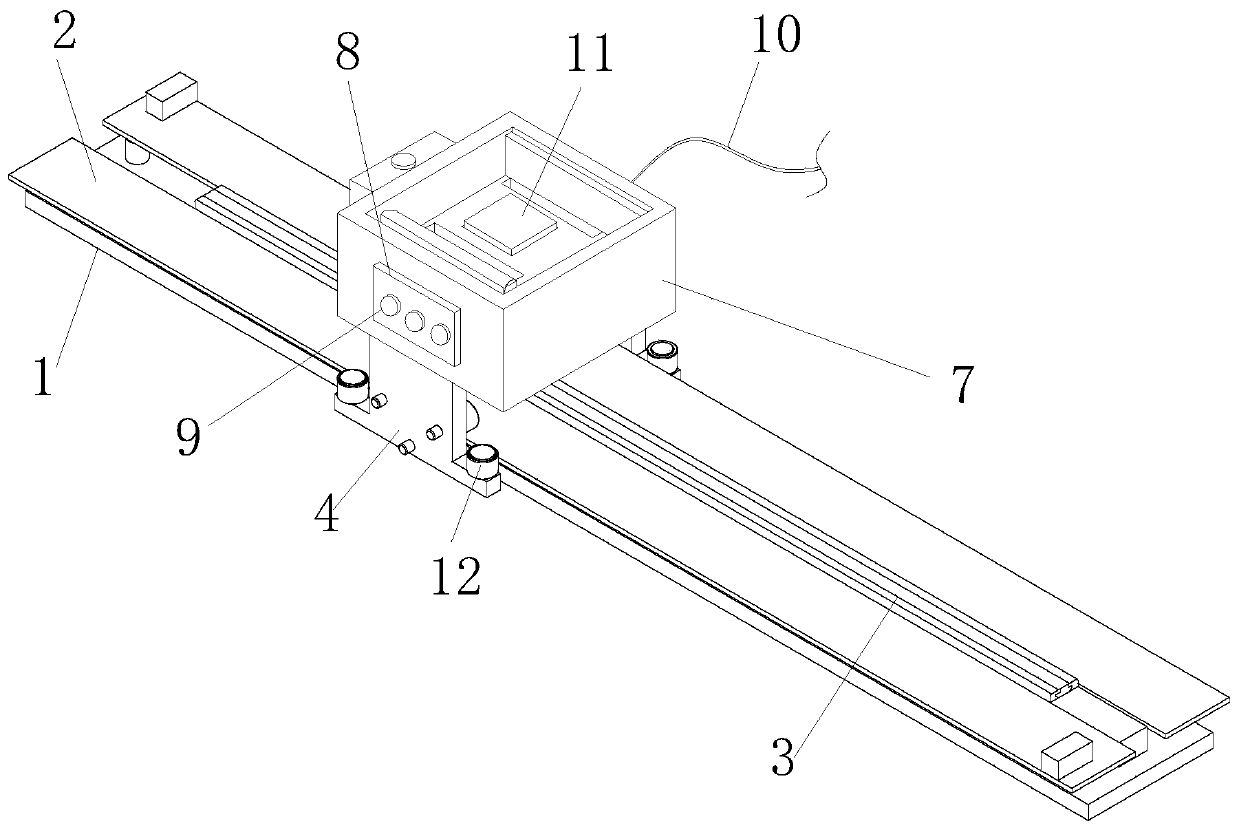

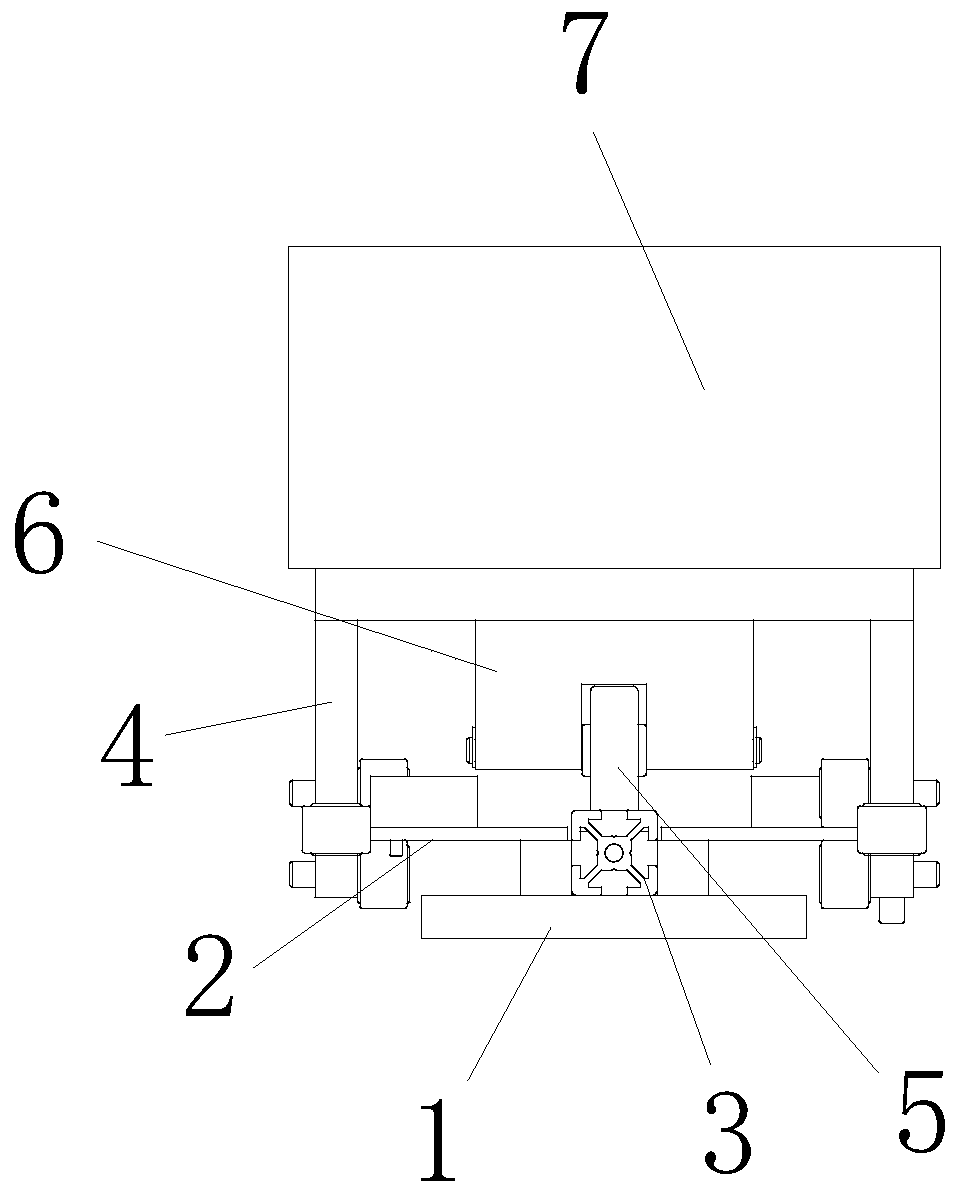

[0034] see figure 1 and figure 2, the present invention provides a sliding mechanism for surface treatment equipment for synthetic processing of new polymer materials through improvement, including a base plate 1, a pulley 5, a support plate 6, a fixed frame 7, auxiliary wheels 12 and a clamping oil delivery mechanism 11, The front and rear ends of the top of the bottom plate 1 are relatively fixed with a horizontal plate 2, the bottom plate 1 is connected with the bottom of the guide rail 3 by bolts, the top of the bottom plate 1 is movably nested with a vertical plate 4, the guide rail 3 is slidingly matched with the bottom of the pulley 5, and the pulley 5 is connected with the inner lower end of the support plate 6 Rotationally fit, and the support plate 6 is fixed to the inner lower end of the vertical plate 4 by electric welding, the vertical plate 4 is locked and fixed with the bottom of the fixed frame 7 by screws, the front end of the fixed frame 7 is provided with a...

Embodiment 2

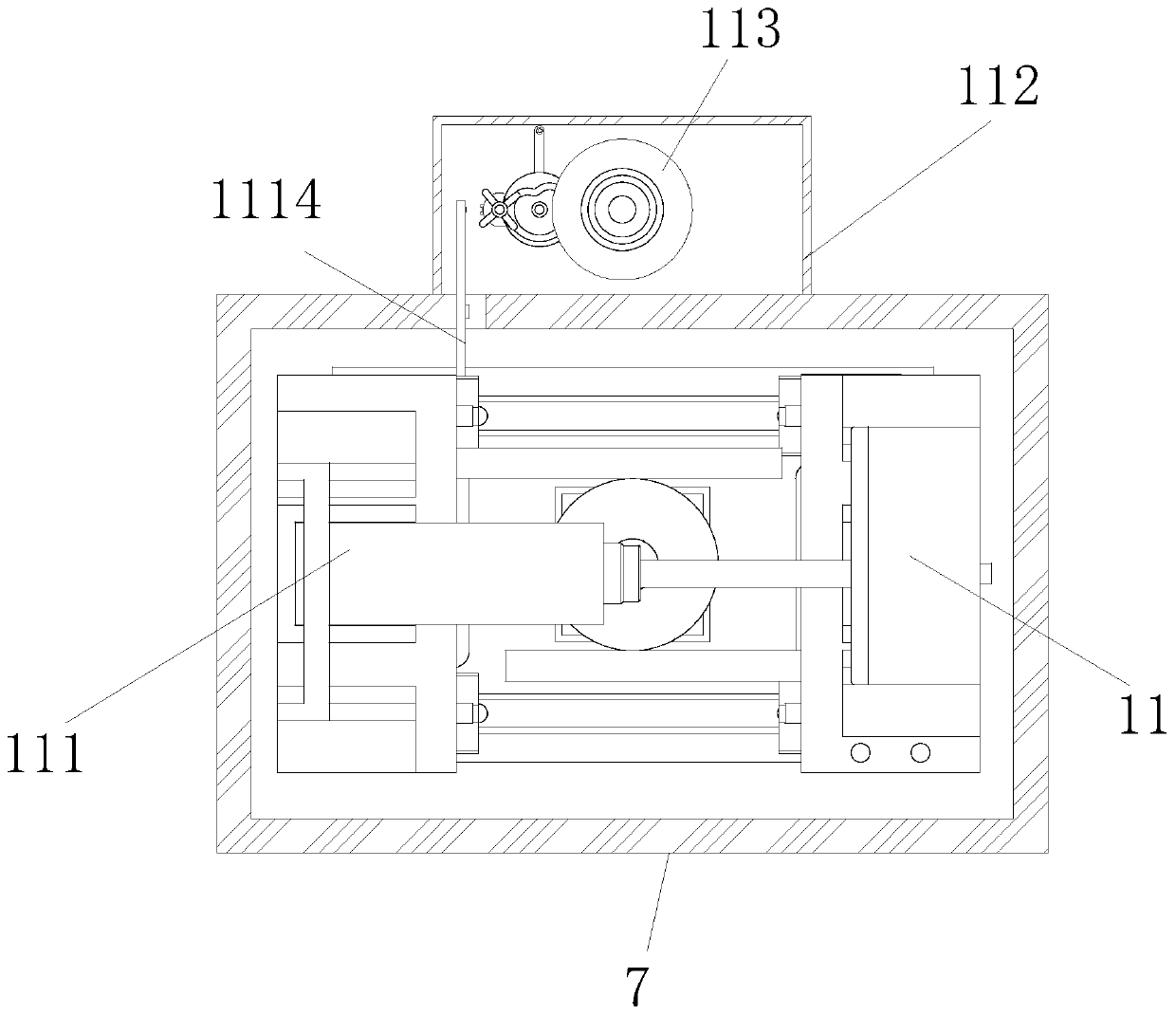

[0042] The present invention provides a sliding mechanism for surface treatment equipment for synthetic processing of new polymer materials through improvement. The second lead block 11173 is located at the upper end of the first lead block 11175, and the pressing rod 11172 drives the second lead block 11173 The inner side of the first power connection block 11175 is plugged in, which is beneficial to energize the electric push rod 1116. The second power connection block 1137 is located on the left side of the rear end of the first power connection block 1114, and when the slider 1113 moves, it will Drive the first lead block 1114 to be plugged in with the left side of the second lead block 1137, which is beneficial to start the micro motor 1136. There are two clamp blocks 1115, and the upper ends of the clamp blocks 1115 are provided with slides. Block 1113 and guide rod 1118.

[0043] The present invention provides a sliding mechanism of surface treatment equipment for synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com