Pole piece structure and lithium ion battery

A lithium-ion battery and pole piece technology, which is applied to battery electrodes, secondary batteries, structural parts, etc., can solve the problems of poor battery self-discharge consistency, poor self-discharge consistency, etc., to avoid internal short circuit and reduce physical self-discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

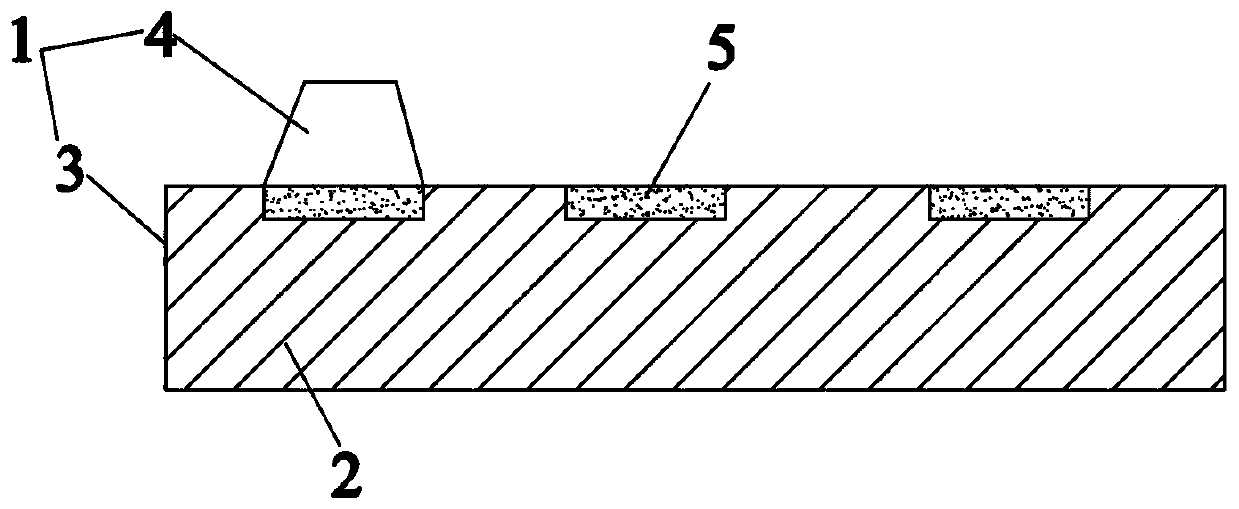

[0039] Such as figure 1 As shown, a pole piece structure includes a current collector 1 and an active material layer 2. The current collector 1 has a main body area 3 and a tab area 4 extending from the main body area. The active material layer 2 is arranged on the surface of the main body area 3. A resistive layer 5 is provided on the tab side of the body region 3 . The resistance value of the resistance layer 5 is greater than or equal to 10 -2 Ω. The resistance layer 5 is an insulating adhesive layer, and the insulating adhesive layer is pasted intermittently on the surface of the active material layer 2 on the ear side of the main body area 3 .

[0040] The preparation method of the pole piece structure is specifically as follows:

[0041] 1) Coating the active material slurry on the surface of the current collector 1 in the main body area 3, forming the active material layer 2 after rolling and drying;

[0042] 2) Die-cut tabs in the blank current collector area adjacen...

Embodiment 2

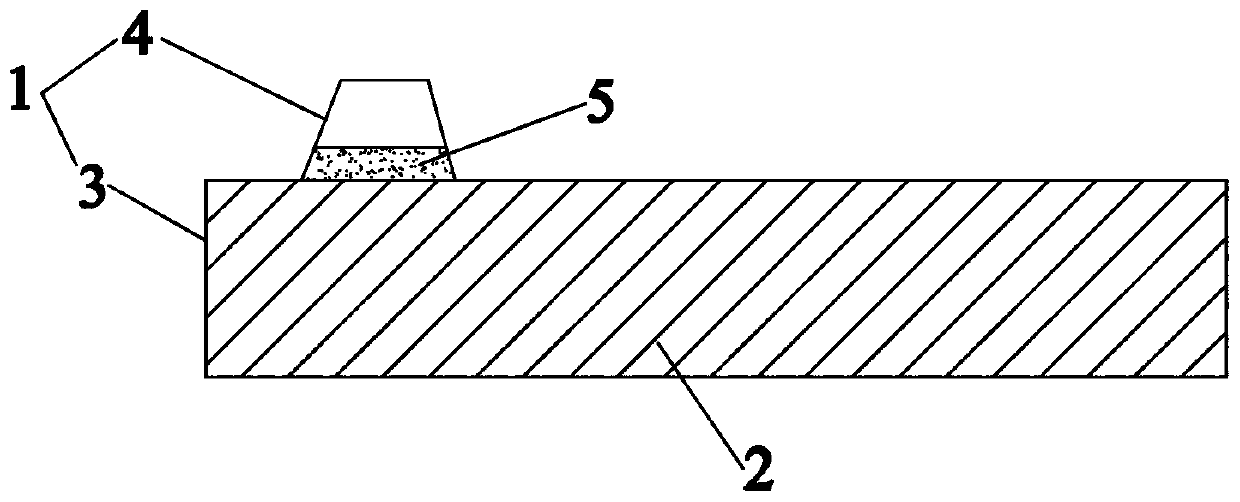

[0045] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that: the surface of the current collector 1 at the root of the tab region 4 is provided with a resistive layer 5 . The resistance layer 5 is a paint layer, and the paint layer contains at least one of conductive material, semiconductor material, insulating material and PTC material.

[0046] The preparation method of the pole piece structure is specifically as follows:

[0047] 1) Coating the active material slurry on the surface of the current collector 1 in the main body area 3, forming the active material layer 2 after rolling and drying;

[0048] 2) Coating the resistance layer slurry on the blank current collector area adjacent to the main body area 3, and forming the resistance layer 5 after rolling and drying;

[0049] 3) Die-cut tabs in the area adjacent to the main body area 3 to obtain the tab area 4. The root of the tab area 4 has a resistance layer 5, and the head of th...

Embodiment 3

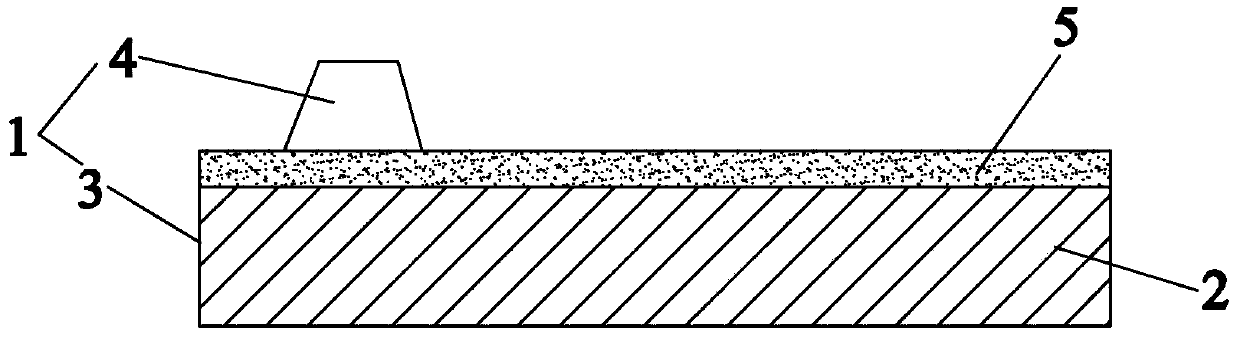

[0052] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is that: the resistance layer 5 is continuously provided on the tab side of the main body region 3 . The resistance layer 5 is an active material layer that has undergone deactivation treatment, that is, acid treatment, laser treatment or high temperature treatment is performed on the active material layer 2 located on the ear side of the main body region 3 .

[0053] The preparation method of the pole piece structure is specifically as follows:

[0054] 1) Coating the active material slurry on the surface of the current collector 1 in the main body area 3, forming the active material layer 2 after rolling and drying;

[0055] 2) Deactivate the area of the active material layer 2 adjacent to the blank current collector to obtain the resistance layer 5;

[0056] 3) Die-cut tabs in the blank current collector area adjacent to the resistance layer 2 to form the tab area 4, and obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com