Composite negative electrode and its preparation method and application

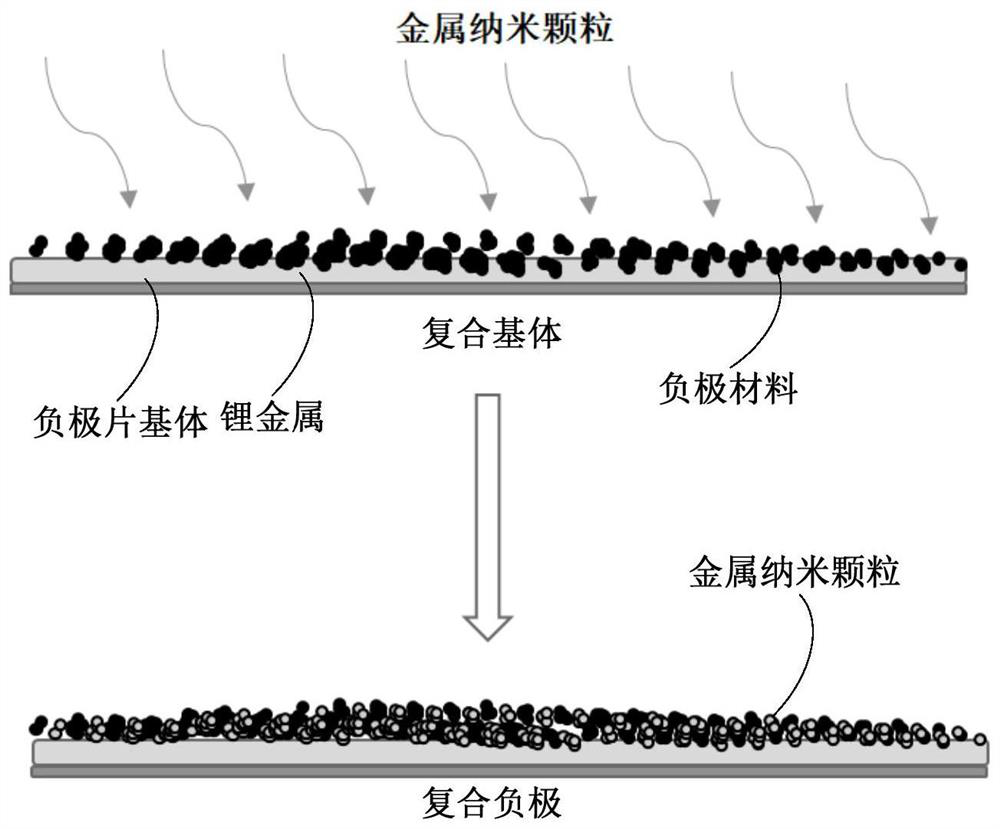

A technology of negative electrode and negative electrode sheet, which is applied in the field of composite negative electrode and its preparation, can solve the problems of lithium dendrite growth, battery short circuit, etc., and achieve the effects of uniform deposition, avoiding internal short circuit, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

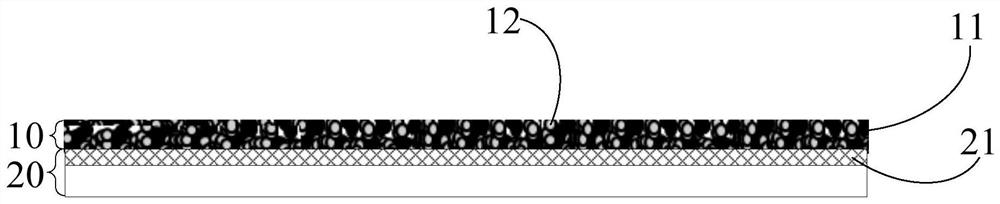

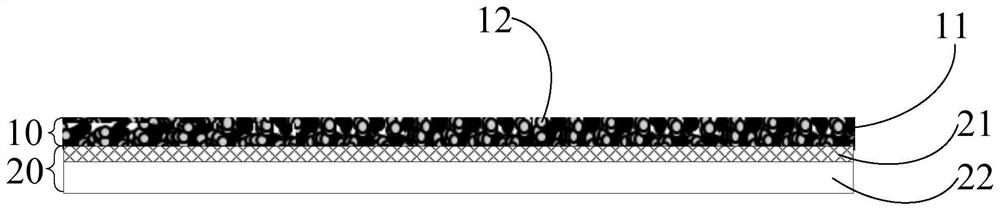

Embodiment 1

[0067] In a dry room environment with a dew point less than -40°C, transfer the silicon-coated aluminum foil to a copper-lithium composite tape, cut it into a square piece of 10×10mm, fix it on a stainless steel evaporation substrate with tape, and place the composite substrate on the In the vacuum chamber of the evaporation equipment, place a tungsten boat containing 5g of pure magnesium at the position of the evaporation source, and evacuate until the vacuum degree reaches 5.0×10 -4 , adjust the heating temperature of the substrate to 100°C, and the rotation rate of the substrate is 8 revolutions / min. By adjusting the current applied to the tungsten boat, the evaporation rate is controlled to 0.01nm / s, and the evaporation is continued while the evaporation rate is kept stable. When the film thickness meter shows that the vapor deposition thickness is 300nm, stop the vapor deposition. After the substrate heating temperature drops to room temperature, open the vent valve to res...

Embodiment 2

[0069] In a dry room environment with a dew point less than -40°C, transfer the carbon-coated aluminum foil to a copper-lithium composite tape, cut it into a square piece of 10×10mm, fix it on a stainless steel evaporation substrate with tape, and place the composite substrate on the In the vacuum chamber of the evaporation equipment, place a tungsten boat containing 5g of pure silver at the position of the evaporation source, and evacuate until the vacuum degree reaches 5.0×10 -4 , adjust the heating temperature of the substrate to 100°C, and the rotation rate of the substrate is 8 revolutions / min. By adjusting the current applied to the tungsten boat, the evaporation rate is controlled to 0.01nm / s, and the evaporation is continued while the evaporation rate is kept stable. When the film thickness meter shows that the evaporation thickness is 400nm, stop the evaporation. After the substrate heating temperature drops to room temperature, open the vent valve to restore the vacuu...

Embodiment 3

[0071] In a dry room environment with a dew point less than -40°C, transfer the carbon-coated aluminum foil to a copper-lithium composite tape, cut it into a square piece of 10×10mm, fix it on a stainless steel evaporation substrate with tape, and place the composite substrate on the In the vacuum chamber of the evaporation equipment, place a tungsten boat containing 5g of pure gold at the position of the evaporation source, and evacuate until the vacuum degree reaches 3.0×10 -4 , adjust the heating temperature of the substrate to 100°C, and the rotation rate of the substrate is 10 revolutions / min. By adjusting the current applied to the tungsten boat, the evaporation rate is controlled to 0.01nm / s, and the evaporation is continued while the evaporation rate is kept stable. Stop the evaporation until the film thickness meter shows that the evaporation thickness is 500nm. After the substrate heating temperature drops to room temperature, open the vent valve to restore the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com