Construction method for preventing airport surface from forming crack and crushed stone

An airport scene and construction method technology, applied in the direction of pavement details, roads, road repair, etc., can solve the problems of sliding and peeling of the overlay layer, large concentration of water inflow in expansion joints, and closure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

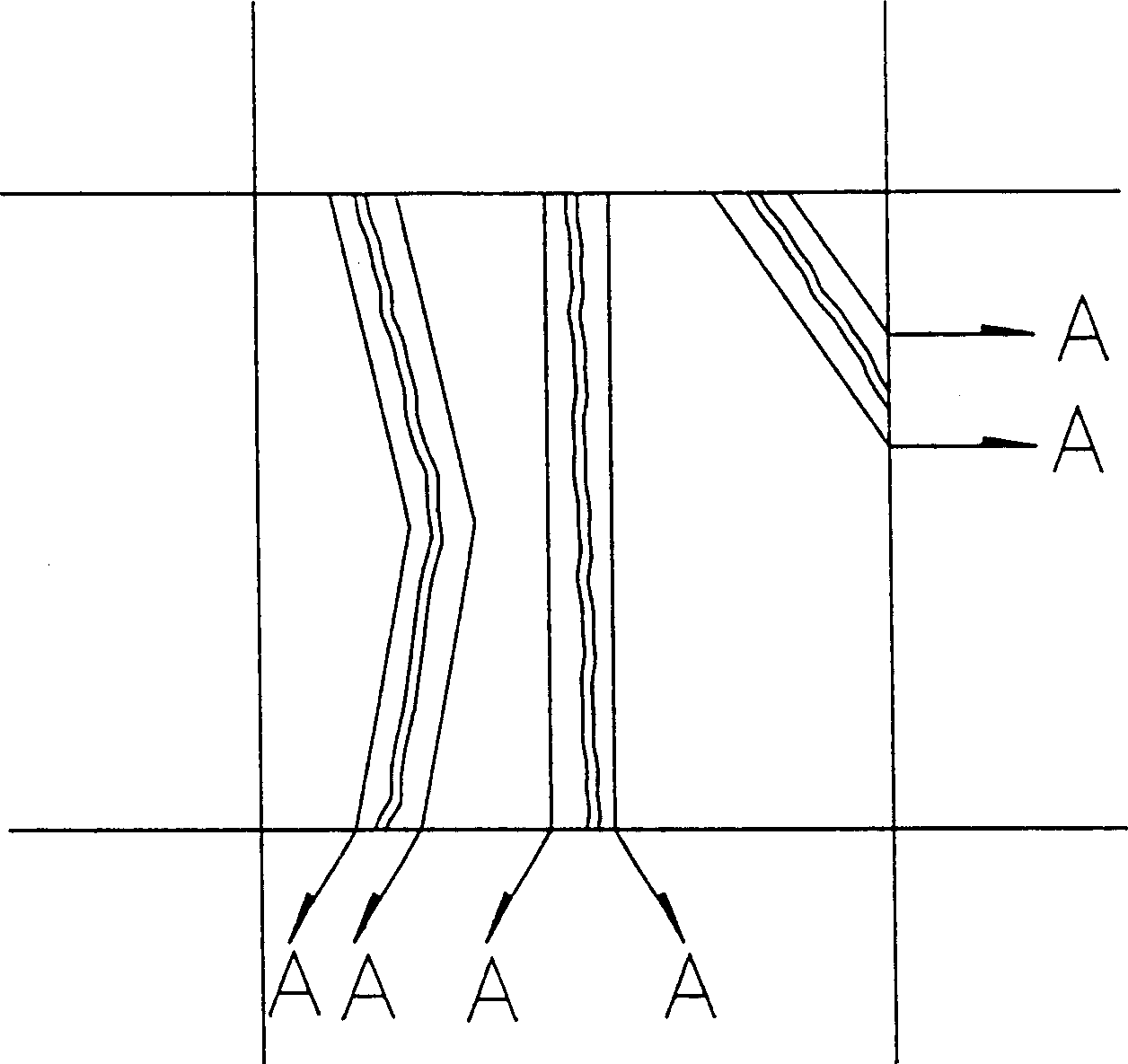

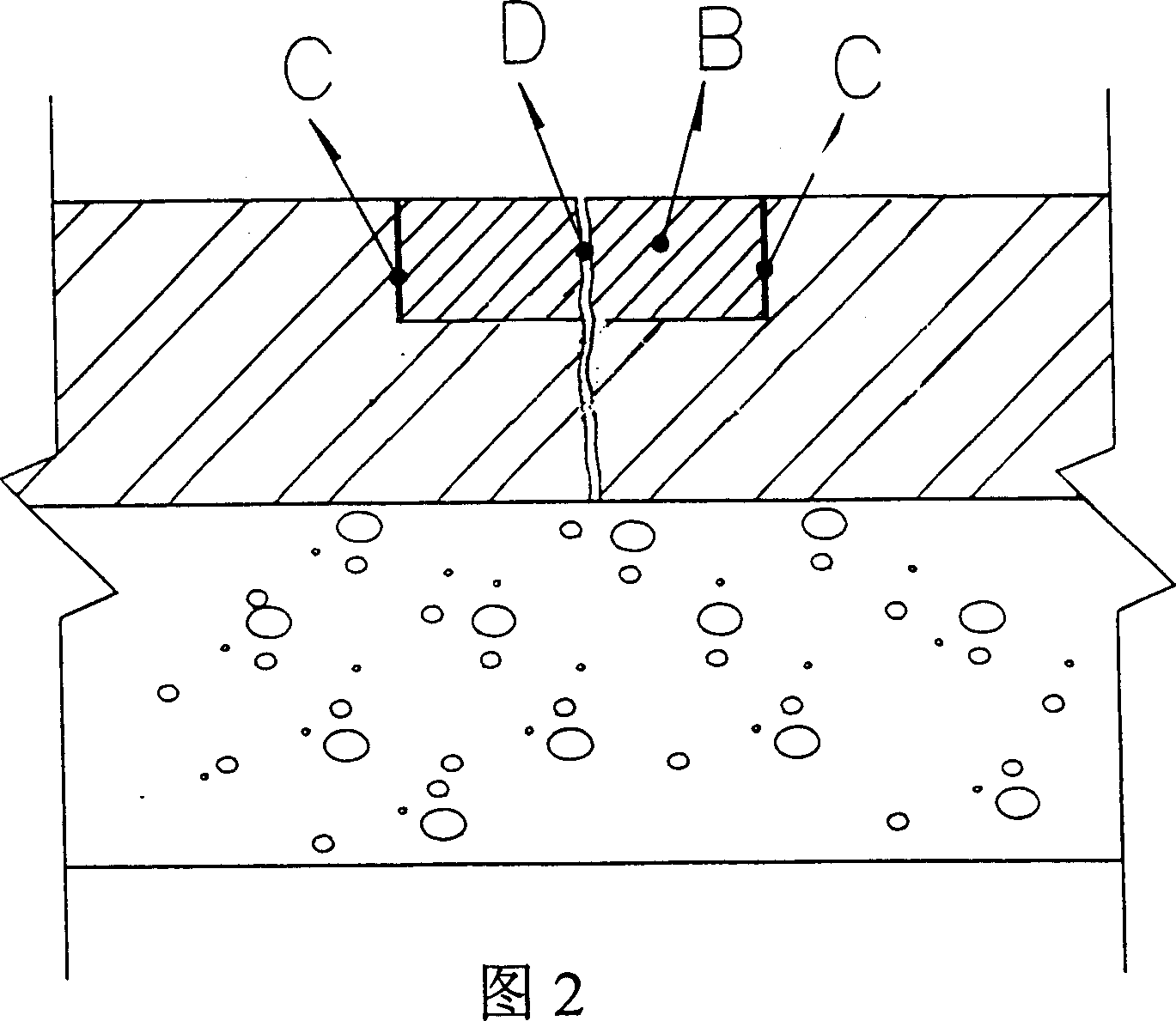

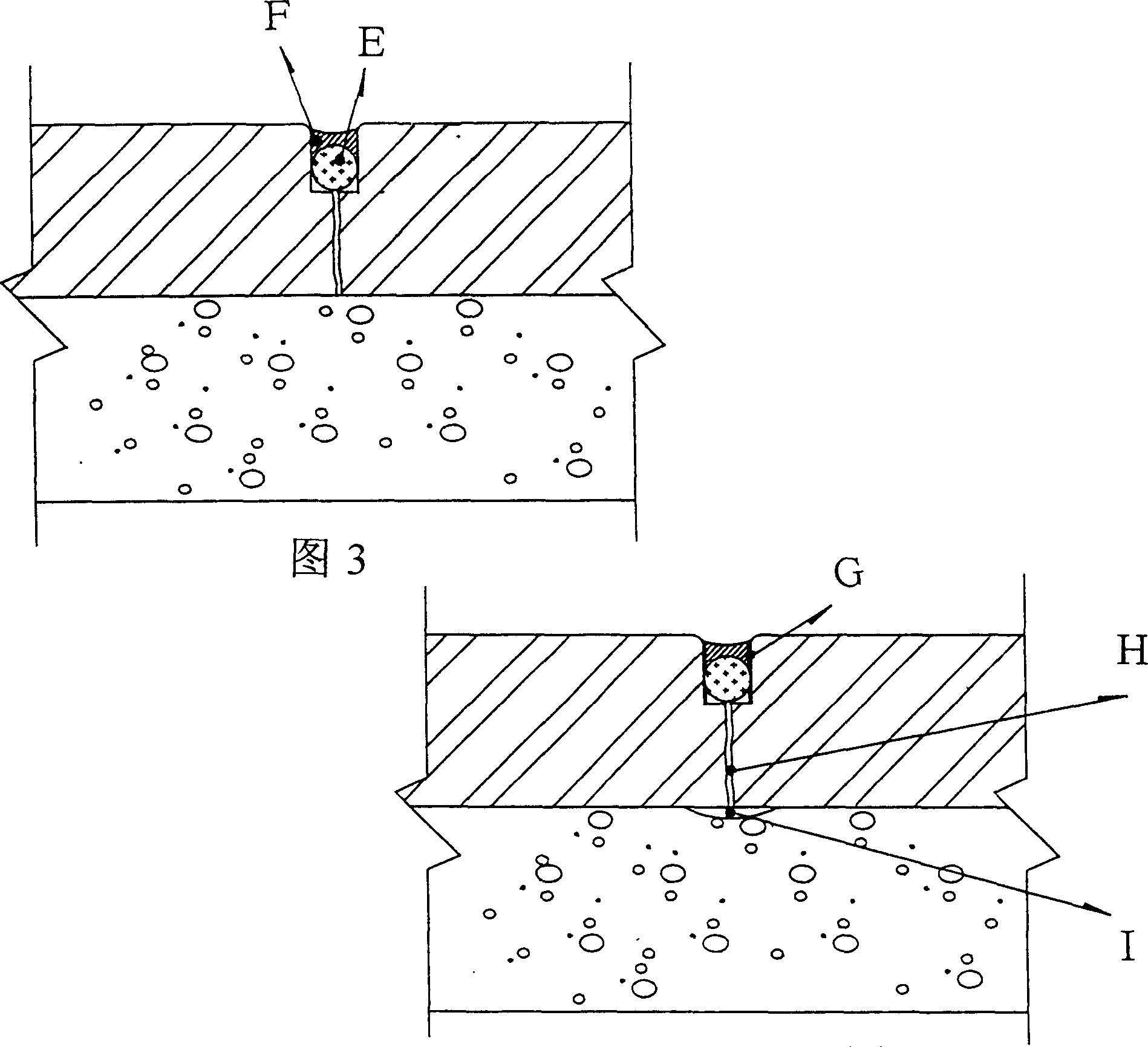

Image

Examples

Embodiment Construction

[0039] Construction materials:

[0040] (1) Manufacturing methods and characteristics of construction materials;

[0041] ①Synthetic asphalt infiltration solvent: After fusing appropriate amount of waterproof asphalt for buildings (hardening and brittle at room temperature) and asphalt for pavement (flowing and viscous at room temperature) and other materials, it is prepared to be viscous at high temperature , the surface layer is elastic at room temperature, but not viscous solvent. Its characteristics are:

[0042] a. Permeability: At high temperature, it can penetrate into the capillary pores and cracks of the construction surface, deeply rooted and integrated into one body, and it will not separate after thermal expansion and contraction.

[0043] b. Weldability: When used together with synthetic asphalt concrete at high temperature, it can weld cracks and repair flat holes.

[0044] c. Bondability: After melting into the construction surface, it has good bondability wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com