A kind of aluminum alloy compartment forming method

A forming method and aluminum alloy technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of inability to realize metal cabin shell forming, complex tooling structure, increased production costs, etc., to improve material utilization The effect of high efficiency, simple tooling structure and simple tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

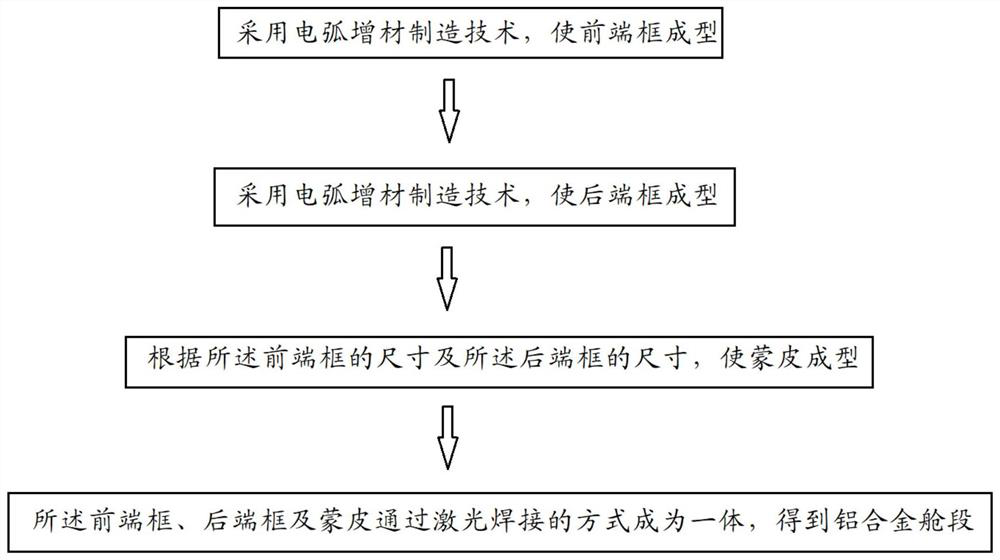

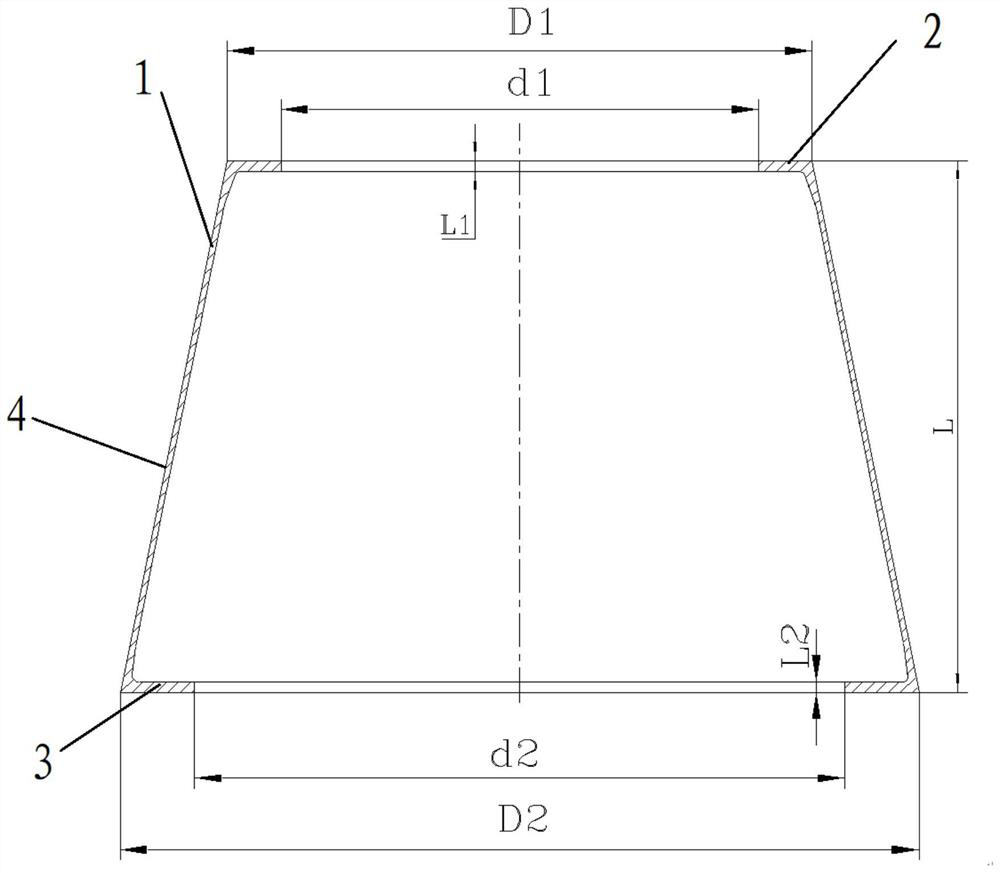

[0024] see Figure 1-5 , a method for forming an aluminum alloy cabin section provided by an embodiment of the present invention includes:

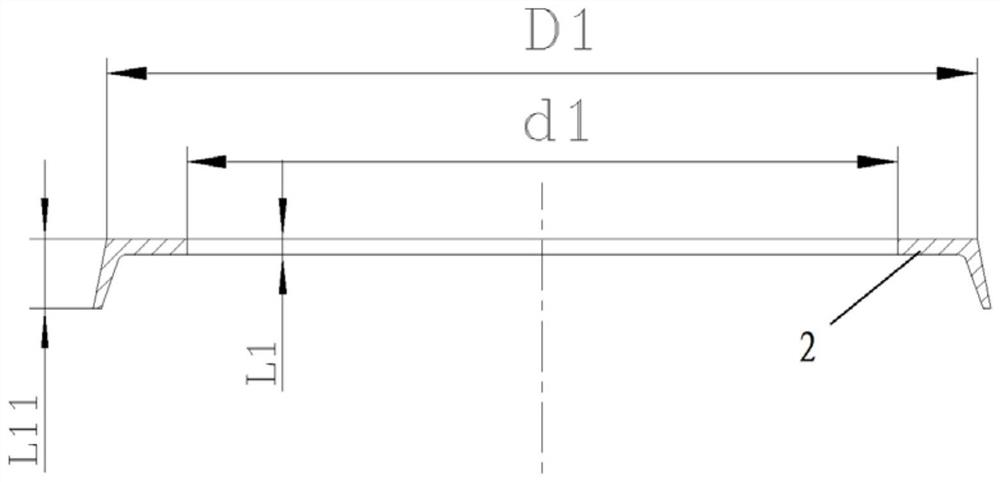

[0025] In step 1, the front-end frame 2 is formed by using the arc additive manufacturing technology.

[0026] In step 2, the rear end frame 3 is formed by using the arc additive manufacturing technology.

[0027] Step 3, according to the size of the front frame 2 and the size of the rear frame 3, the skin 4 is formed.

[0028] Step 4, the front end frame 2, the rear end frame 3 and the skin 4 are integrated by laser welding to obtain the aluminum alloy cabin section 1.

[0029] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The front-end frame 2 is formed by using the arc additive manufacturing technology, and the rear-end frame 3 is formed by using the arc-additive manufacturing technology. Therefore, the front-end frame 2 and the rear-end frame 3 are formed by arc additive manufacturing. Technology, using the principle of layer-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com