A conveying wood splitter for biomass power generation

A biomass power generation and wood splitting machine technology, which is applied in the direction of wood splitting devices, manufacturing tools, wood processing appliances, etc., can solve the problems of high-power electrical equipment that cannot be used, the circuit is not perfected, and the labor intensity of operators is increased. Achieve the effects of preventing impact, preventing blade shaking, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

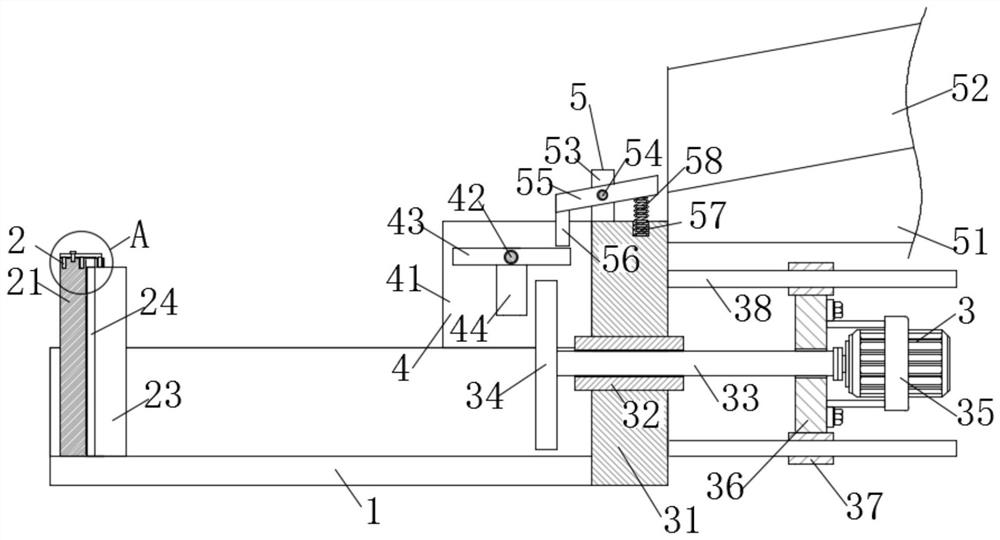

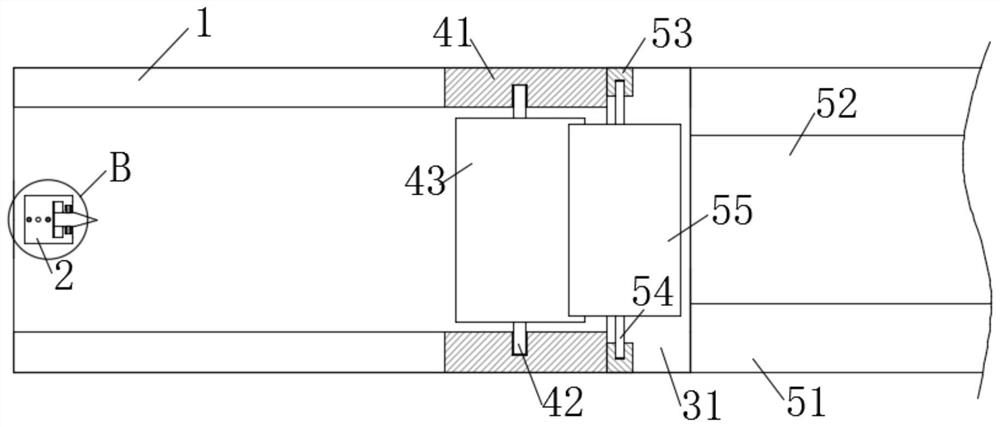

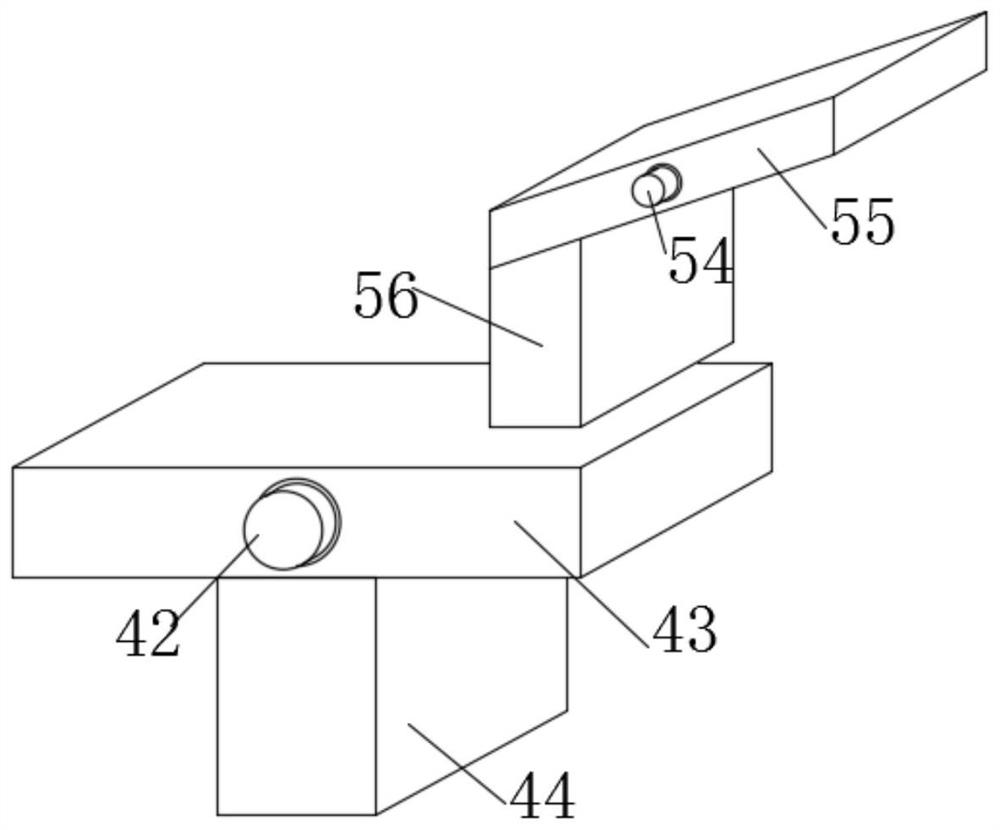

[0027] Example: such as Figure 1-6 As shown, a wood splitting machine for biomass power generation in the present invention includes a semi-cylinder 1, a splitting mechanism 2 is installed on the inner wall of one end of the semi-cylinder 1, and a pushing mechanism 3 is installed on the end of the semi-cylinder 1 away from the splitting mechanism 2. The top of the half cylinder 1 is equipped with a linkage mechanism 4 away from the end of the splitting mechanism 2, and the upper end of the pushing mechanism 3 is equipped with a blanking mechanism 5.

[0028] Split mechanism 2 comprises knife seat 21, and knife seat 21 is fixedly connected on the end inner wall of semi-cylinder 1, and knife seat 21 is provided with T-shaped chute 22 near the side of pushing mechanism 3, and the top of T-shaped chute 22 and knife The outside of the seat 21 is connected, and the inside of the T-shaped chute 22 is slidably connected with a cutter 23. The cutter 23 is fixedly connected to both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com