Sweet tipping paper and preparation method thereof

A technology for tipping paper and tipping paper base paper, applied in the field of cigarettes, can solve the problems of mixing other flavors, affecting human health, easily producing harmful substances, etc., achieving stable sweet coating, improving taste enjoyment, and satisfying sweet taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

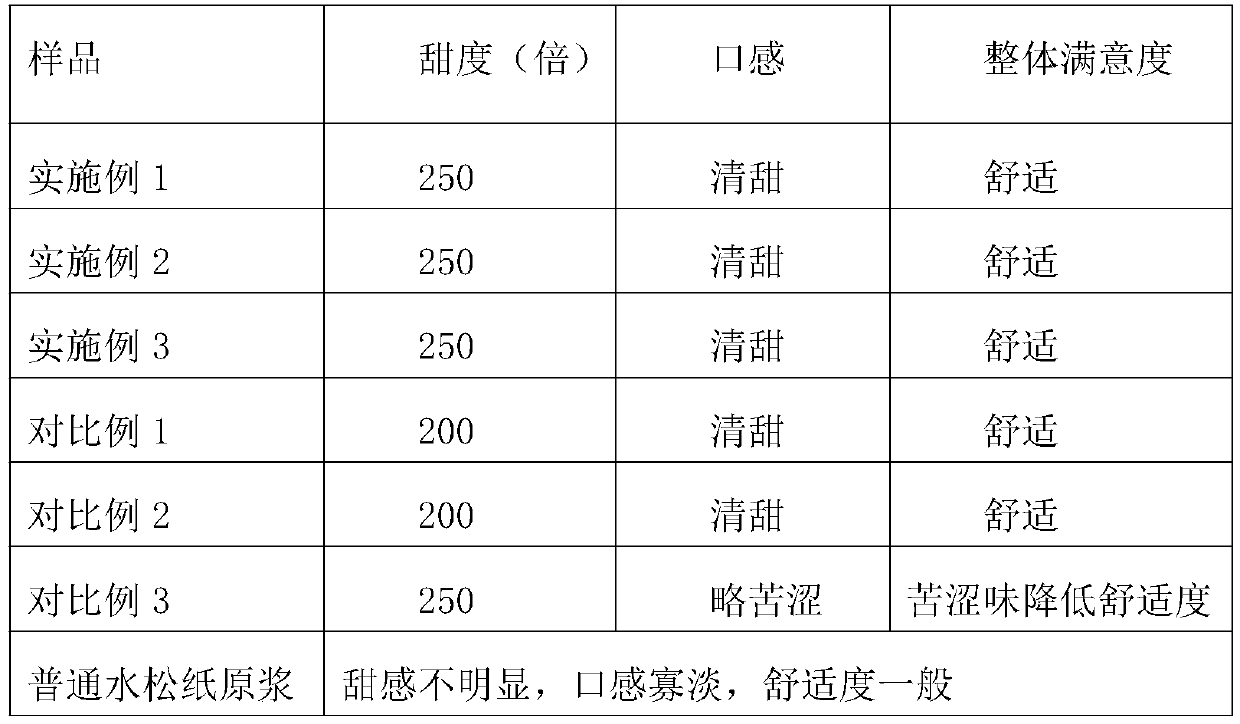

Examples

Embodiment 1

[0029] A sweet tipping paper, comprising tipping paper base paper and a sweet coating applied on the tipping paper base paper, the sweet coating takes raw materials in parts by weight as follows: 10 parts of licorice extract, 8 parts of manna alcohol, 6 parts stevia extract, 2 parts malic acid, 4 parts thickener, 2 parts polyacrylamide, 2 parts sizing agent, 50 parts edible ethanol, 3 parts edible clove oil, 25 parts deionized water.

[0030] In this embodiment, the sizing agent is a mixture of carboxymethyl cellulose and modified starch, and the mass ratio of carboxymethyl cellulose and modified starch in the mixture is 1:0.5; the thickener is melon A mixture of guar gum and xanthan gum, the mass ratio of guar gum and xanthan gum in the mixture is 1:1; the processing aid is polyacrylamide.

[0031] In this example, the sweetened tipping paper is prepared according to the following method:

[0032] S1: Add licorice extract, mannitol, stevia extract, malic acid, and thickener ...

Embodiment 2

[0038] A sweet tipping paper, comprising tipping paper base paper and a sweet coating applied on the tipping paper base paper, the sweet coating takes raw materials in the following parts by weight: 20 parts of licorice extract, 12 parts of manna alcohol, 8 parts stevia extract, 3 parts malic acid, 6 parts thickener, 4 parts polyacrylamide, 4 parts sizing agent, 60 parts edible ethanol, 5 parts edible clove oil, 30 parts deionized water.

[0039] In this embodiment, the sizing agent is a mixture of carboxymethyl cellulose and modified starch, and the mass ratio of carboxymethyl cellulose and modified starch in the mixture is 1:0.6; the thickener is melon A mixture of guar gum and xanthan gum, the mass ratio of guar gum and xanthan gum in the mixture is 1:1; the processing aid is polyacrylamide.

[0040] In this example, the sweetened tipping paper is prepared according to the following method:

[0041] S1: Add licorice extract, mannitol, stevia extract, malic acid, and thicke...

Embodiment 3

[0047] A sweet tipping paper, comprising tipping paper base paper and a sweet coating applied on the tipping paper base paper, the sweet coating takes raw materials in parts by weight as follows: 15 parts of licorice extract, 10 parts of manna alcohol, 7 parts stevia extract, 2.5 parts malic acid, 5 parts thickener, 3 parts polyacrylamide, 3 parts sizing agent, 55 parts edible ethanol, 4 parts edible clove oil, 28 parts deionized water.

[0048] In this embodiment, the sizing agent is a mixture of carboxymethyl cellulose and modified starch, and the mass ratio of carboxymethyl cellulose and modified starch in the mixture is 1:0.55; the thickener is melon A mixture of guar gum and xanthan gum, the mass ratio of guar gum and xanthan gum in the mixture is 1:1; the processing aid is polyacrylamide.

[0049] In this example, the sweetened tipping paper is prepared according to the following method:

[0050] S1: Add licorice extract, mannitol, stevia extract, malic acid, and thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com