Safe operation system and method for asphalt mixture plant-mixed hot regeneration equipment

A technology of asphalt mixture and safe operation, which is applied in roads, road repairs, roads, etc., can solve the problems of large impact on production progress, difficulty in intuitive observation, and long time consumption, so as to achieve small impact on enterprise production, ensure safe and stable operation, and achieve the best results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments.

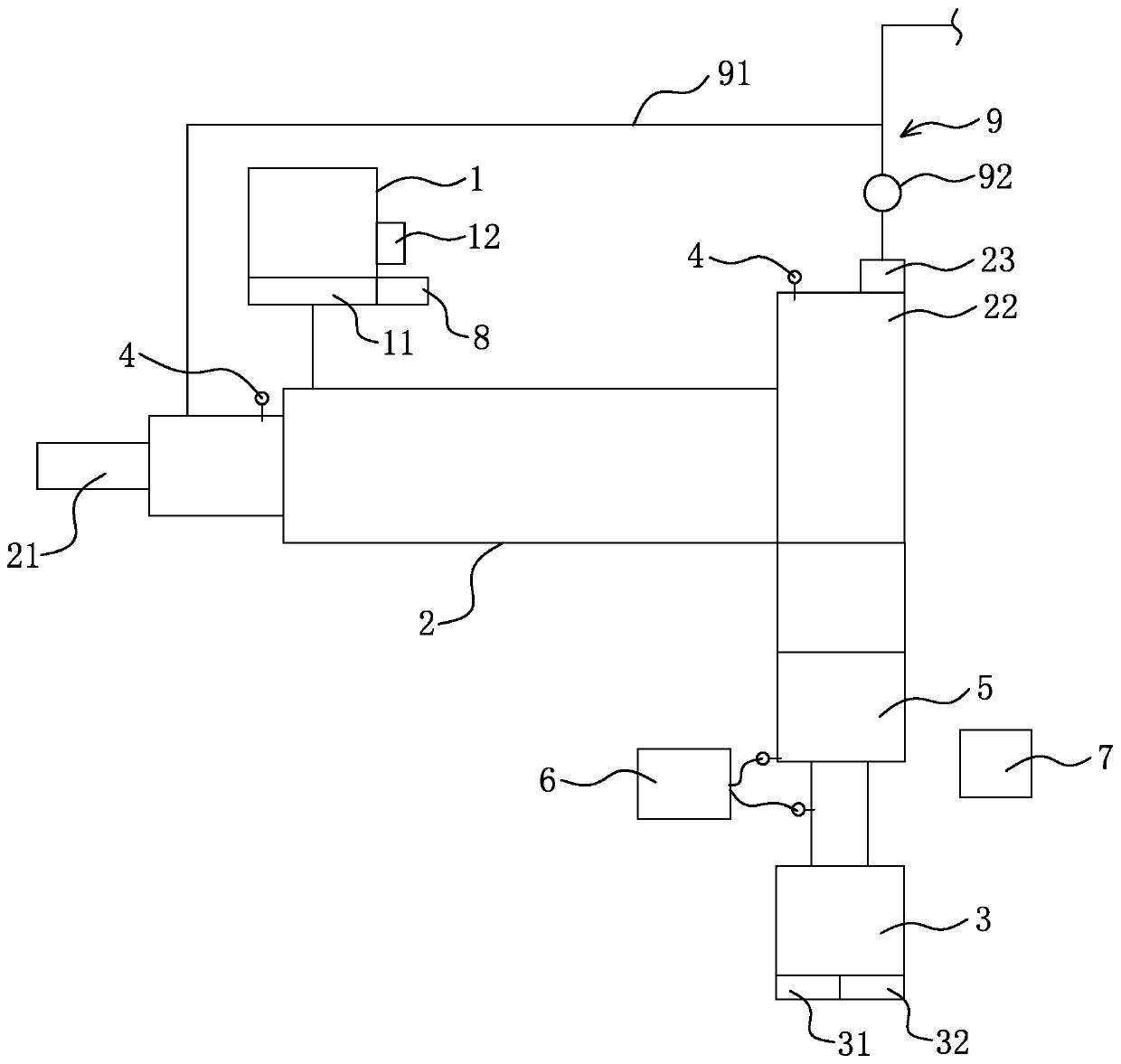

[0021] refer to figure 1 As shown in the figure, a safety operation system for thermal recycling equipment in an asphalt mixture plant includes a cold material bin 1, a recycled material drying drum 2, a mixing tank 3, a temperature detection device 4, a metering device 5, an oil injection device 6, and a flame detector Device 7, material breaking detection device 8, waste gas treatment device 9, controller.

[0022] There is a cold material valve 11 at the outlet of the cold material bin 1, and the cold material bin 1 sends cold recycled material toward the recycled material drying drum. The cold material bin 1 is equipped with a vibration device 12, and the broken material detection device 8 corresponds to the cold material valve 11. position to detect the discharge state of the cold material bin 1, and the material breaking detection device 8 is connected to the controller signal; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com