Gas cooker capable of avoiding gas poisoning

A gas stove and gas technology, applied in the field of kitchen utensils, can solve problems such as gas poisoning, and achieve the effect of avoiding a large amount of emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

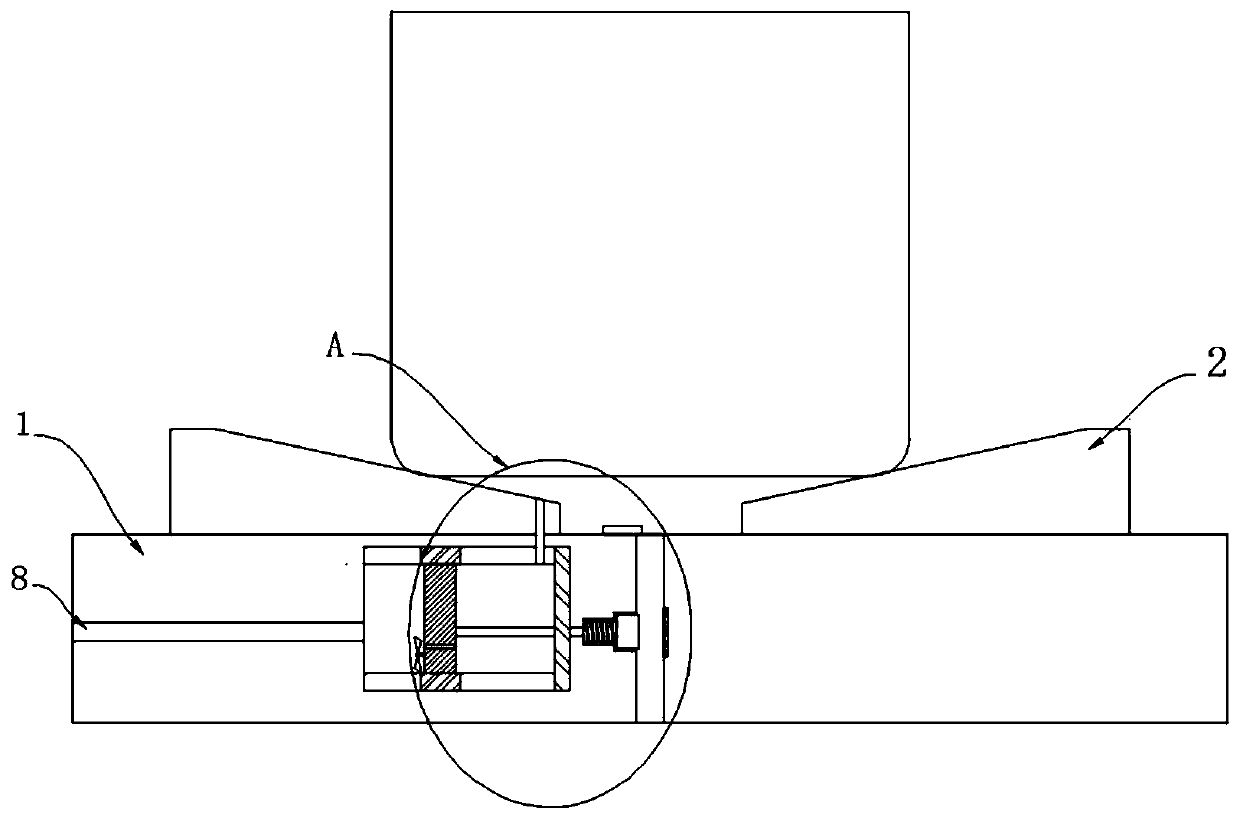

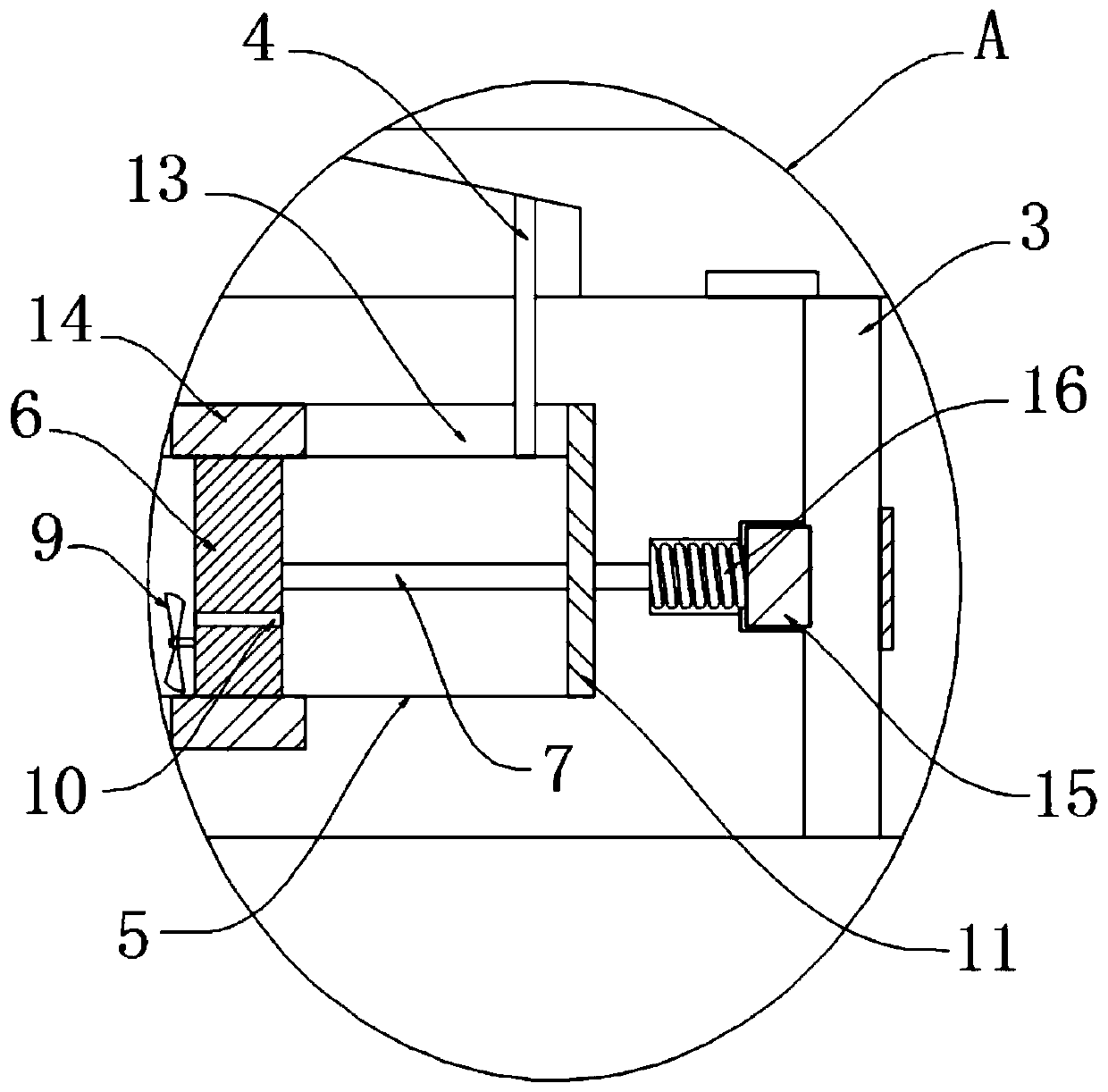

[0019] refer to Figure 1-2 , a gas stove for avoiding gas poisoning, comprising a stove 1 and a stove 2, the stove 1 is provided with an air intake passage 3, an igniter is provided at the connection between the air intake passage 3 and the outside, the stove 2 and the stove 1 A ventilation hole 4 is opened together, a sliding chamber 5 communicating with the ventilation hole 4 is provided in the stove 1, a separation plate 6 is sealed and slidably connected to the sliding chamber 5, and a reaction layer is fixedly connected to the side of the separation plate 6 close to the ventilation hole 4 And it is fixedly connected with a strut 7 , the strut 7 runs through the side wall of the sliding chamber 5 and communicates with the air intake passage 3 .

[0020] The side of the slide chamber 5 away from the pole 7 communicates with the outside world and is provided with an outlet 8. The side of the separation plate 6 close to the outlet 8 is connected with an impeller 9. The impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com